roudyroy1

Active member

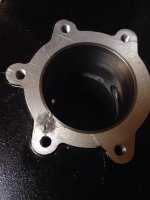

Let me explain, I'm helping my buddy rebuild his 98 200 blaster(atv). now he got a whole top end rebuild kit, pulled the cyl out of the box and look at this.

Looks it's been nicked where the head and gasket seat.... Not good. So we need to fix this.

Seeing as it's air cooled, I'm thinking we can very gently knock the high part off with a mill file, then place the cyl on some 600grit wet sand paper on a sheet of glass until it's flat, then if there is any remaining divot, fill it with some jb weld(good to 600f), wet sand again, then put it together. Not pretty but, he got it cheap.

Thoughts???

Looks it's been nicked where the head and gasket seat.... Not good. So we need to fix this.

Seeing as it's air cooled, I'm thinking we can very gently knock the high part off with a mill file, then place the cyl on some 600grit wet sand paper on a sheet of glass until it's flat, then if there is any remaining divot, fill it with some jb weld(good to 600f), wet sand again, then put it together. Not pretty but, he got it cheap.

Thoughts???

rx1jim

New member

It is hard to see the extent of the damage from the photo. Your suggested procedure sounds reasonable. Be sure to use a thick piece of glass (I used to use a 12" dia. piece of glass which is 3/4" thick just for this purpose but recently got a granite surface plate). If after you polishing process there is still a shallow divot, the surface should seal fine. i would be concerned with a remaining divot if it was in the shape of a line or scratch rather than an isolated divot. After you finish the polishing, match the surface up to the head gasket and see where the remaining damage falls. The head gasket will form to the divot under the required torque settings. My bet is your sugested procedure will produce fine results. Be sure to apply pressure as evenly as possible during the polishing to maintain flatness of the original surface. I use a lightweight oil like WD-40 while polishing on the paper. Wash the cylinder in hot soap and water (I use dishwashing detergent) to release all the grit from the cylinder honing and surface polishing, cleaning with solvent only is not nearly good enough. Good luck with the rebuild and darn nice of you to help out your friend!!!!

Jim

Jim

Let me explain, I'm helping my buddy rebuild his 98 200 blaster(atv). now he got a whole top end rebuild kit, pulled the cyl out of the box and look at this.View attachment 58441

Looks it's been nicked where the head and gasket seat.... Not good. So we need to fix this.

Seeing as it's air cooled, I'm thinking we can very gently knock the high part off with a mill file, then place the cyl on some 600grit wet sand paper on a sheet of glass until it's flat, then if there is any remaining divot, fill it with some jb weld(good to 600f), wet sand again, then put it together. Not pretty but, he got it cheap.

Thoughts???

It sounds like what I would do.

roudyroy1

Active member

roudyroy1

Active member

Contacted seller, said they would replace it if it fails. Might as well give it a shot. Thanks for the help guys!

I would chase those threads out with a tap too, just to be safe.

roudyroy1

Active member

definitely doing that too!

roudyroy1

Active member

Hit all the gaskets with some hightac to ensure a good seal. Didn't end up jb welding the divot as it cleaned up nicely. Engine is together and running, thanks guys.

roudyroy1

Active member

View attachment 58460

On another note, what do you think the cause of this was....

Snow ingestion can cause that.

roudyroy1

Active member

Snow ingestion can cause that.

It's and atv engine and that's the exhaust side, so It can't be that. Looks like it though.

roudyroy1

Active member

Bump for a piston diagnostic

Throttle Junkie35

New member

I would bet you have at least some other light scratches on the other side of the exhaust port as well?? Maybe on the intake too?? In my opinion, it looks like someone didnt let the engine warm up properly before opening up the throttle.