Youllbe2nd

New member

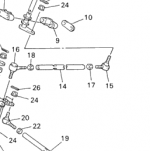

Anyone made up their own steering block? After pulling my motor to do some porting work i figured I would correct the slop in my steering. 99% of the slop is in the lower steering block. I was pretty astonished to see it was made of plastic...never had a close look at them. I'm thinking about two things. Maybe I'll make my own aluminum one or maybe bore this plastic out a bit and put in an oil lite split bushing... maybe the coffee tin trick?? Opinions welcome [emoji4]

Sent from my E6560C using Tapatalk

Sent from my E6560C using Tapatalk

Youllbe2nd

New member

There is a company that makes one already. Made for four strokes but same part even though the number is different.

It is unnessasary. you can tighten up the one you have by filing a little off the steel collars that keep the nut from over tightening the bushing. Drill the bushing with a tiny hole, drill and tap the metal plate that clamps it for a grease fitting dead center. Smooth the rust and such off the metal, polish it up a bit. Install everything so it is snug but not so tight it causes drag, this is a fine line so go slow when removing metal and checking. Doesn't take much. once together, grease with very thin grease as this area does not get warm and will cause the steering to move hard. While you down there replacing you tie rod with cut a piece of inner tube with a hole in it to cover your tie rode end. water is continuously being dripped on the tie rod end that faces upward to collect it. Makes them wear out prematurely. Pack grease in it and cover it with the rubber so the water runs off.

You can also tighten up the upper one the same way. Your front end needs some love as well. Article below.

It is unnessasary. you can tighten up the one you have by filing a little off the steel collars that keep the nut from over tightening the bushing. Drill the bushing with a tiny hole, drill and tap the metal plate that clamps it for a grease fitting dead center. Smooth the rust and such off the metal, polish it up a bit. Install everything so it is snug but not so tight it causes drag, this is a fine line so go slow when removing metal and checking. Doesn't take much. once together, grease with very thin grease as this area does not get warm and will cause the steering to move hard. While you down there replacing you tie rod with cut a piece of inner tube with a hole in it to cover your tie rode end. water is continuously being dripped on the tie rod end that faces upward to collect it. Makes them wear out prematurely. Pack grease in it and cover it with the rubber so the water runs off.

You can also tighten up the upper one the same way. Your front end needs some love as well. Article below.

Youllbe2nd

New member

Well this will save me alot of work! Great info thanks alot. I have a couple questions.There is a company that makes one already. Made for four strokes but same part even though the number is different.

It is unnessasary. you can tighten up the one you have by filing a little off the steel collars that keep the nut from over tightening the bushing. Drill the bushing with a tiny hole, drill and tap the metal plate that clamps it for a grease fitting dead center. Smooth the rust and such off the metal, polish it up a bit. Install everything so it is snug but not so tight it causes drag, this is a fine line so go slow when removing metal and checking. Doesn't take much. once together, grease with very thin grease as this area does not get warm and will cause the steering to move hard. While you down there replacing you tie rod with cut a piece of inner tube with a hole in it to cover your tie rode end. water is continuously being dripped on the tie rod end that faces upward to collect it. Makes them wear out prematurely. Pack grease in it and cover it with the rubber so the water runs off.

You can also tighten up the upper one the same way. Your front end needs some love as well. Article below.

How tiny a hole are we talkin? Smallest bits I have are 40 thou.

Should I file some of the plastic down too? Or just the steel collars?

I'm not totally following what you mean with the inner tube...cover with rubber and pack with grease I get. How do I get an peice of inner tube to stay on there and hold the grease?

Thanks again [emoji4]

Sent from my E6560C using Tapatalk

tiny hole, anything that grease will flow through into the shaft area.

Just the collars, the plastic will crush a bit. Also, sometimes the slack in these is side to side(usually a four stroke thing) so to tighten up the sides sometimes it is nessasary to drill a hole in the block and wind a couple screws into it. This pushes some material inward.

any old piece of rubber. Your just making an umbrella for your tie rode end so falling water will run off it instead of into it, washing out all the grease.

Just the collars, the plastic will crush a bit. Also, sometimes the slack in these is side to side(usually a four stroke thing) so to tighten up the sides sometimes it is nessasary to drill a hole in the block and wind a couple screws into it. This pushes some material inward.

any old piece of rubber. Your just making an umbrella for your tie rode end so falling water will run off it instead of into it, washing out all the grease.

Youllbe2nd

New member

Thanks again for your help

Sent from my E6560C using Tapatalk

Sent from my E6560C using Tapatalk