Black Bear

New member

Folks,

Seems like I remember stock secondary settings at A-2? Do the secondary settings get progressively more skewed torwards the low end as you move to the B and C settings? If so anyone running C settings?

Seems like I remember stock secondary settings at A-2? Do the secondary settings get progressively more skewed torwards the low end as you move to the B and C settings? If so anyone running C settings?

Throttle Junkie35

New member

A-2 is correct. A-2 is 50*. The next step up is B-2 which is 60* and a step below A-2 is C-2 which is 40*. make sense?? I know there is a diagram on this site somewhere. I will see if I can find it. Generally, less of a wind= less rpm, more prewind = more RPM. The pre wind will affect max rpm, up shift, and back shift. This is used as a fine tuning adjustment once the rest of the clutching is where you want it.

The best thing I ever did was spend almost a week of changing clutch components, testing and taking notes. I learned more by changing parts myself and feeling the difference in how the sled responded to those changes than anyone could have ever explained to me up to that point. Get yourself some different springs and helixes if you want to play with the secondary. Make sure your primary is in perfect working order before going anywhere else. Also, make sure you have a couple of new belts of the same brand.

The best thing I ever did was spend almost a week of changing clutch components, testing and taking notes. I learned more by changing parts myself and feeling the difference in how the sled responded to those changes than anyone could have ever explained to me up to that point. Get yourself some different springs and helixes if you want to play with the secondary. Make sure your primary is in perfect working order before going anywhere else. Also, make sure you have a couple of new belts of the same brand.

Black Bear

New member

Thanks for the explanation Throttle Junkie. Separate question do you know what the thread size is on the Exciter Crankshaft? I finally did get the bastard clutch (QuickShift Magnum Gold) off one of the engines that I have needing rebuild. The first couple of threads are mangled. I was thinking I could run a tap in an out a couple of times and it may be ok.

Throttle Junkie35

New member

Well....I dont know the thread size in the crank end but I did damage the first couple of thread on one of my engines a while back by using a puller that had too short of a stub on it. I used a dremmel and ground out the first couple of threads. A thread chaser would have been a better option if I had one on hand. So....thats all I got for ya.

1/2" x 20. just an fyi, your spring's color will dictate the setting. if the spring has been changed from the stock color, angles will change.

Throttle Junkie35

New member

Good point snow dad. The settings as I explained it are for pink and white springs that I know of for sure. I believe the yellow/green? has totally different spring tab locations that make it differ. These are the most common springs from that era as far as I can tell.

Black Bear

New member

Big thanks to you both. Used a 1/2-20 to clean up the first few threads and its fine.

toydoc

Member

I use to drill a new hole in the driven sheave and set the secondary tension to what I wanted. I'd clamp vice grip on the outside top driven, use a fish scale and check it in LBS.

If I remember right, it like 14lbs of tension. I check factory holes combos, log data of lbs @ A-2.. and so on.

From the data you find what factory setting is above and below my target 14lbs. Then / the distance and it would be real close to what I was looking for.

If I remember right, it like 14lbs of tension. I check factory holes combos, log data of lbs @ A-2.. and so on.

From the data you find what factory setting is above and below my target 14lbs. Then / the distance and it would be real close to what I was looking for.

Secondary clutch...

Quote:

Do NOT change the secondary clutch to adjust engine rpm.

I’ve seen too many people increase the pre-tension on their secondary to bring up their engine rpm, myself included.

You are shooting yourself in the foot !!!!

It decreases the efficiency of transmission of power to the track while adversely affecting the ability of the secondary to keep the shift curve flat.

Once you have your rpm where you want it, you next job is to get it to shift out the way you want.

That’s the job of the secondary.

The combination of spring and helix is what determines this.

Multi-angle is what I prefer.

The secondary spring directly equates to side-force on the belt.

The idea is that the more side-force you have on the belt, the less efficient it is because of belt drag.

Yamaha Secondary pre-tension (wind) should be around 16-24 ft lbs.

What I try to do is get to the minimum side-force possible without slipping the belt in the secondary.

Too much side-force and the clutch will back-shift too fast and put you in too low of a ratio and over rev when you stab the throttle out of a corner.

Too little and it won’t back-shift fast enough and it will react sluggishly (bog) and you’ll loose rpm climbing hills or trying to maintain high speeds.

// Tom Hartman ( CEO and owner of: http://www.hartmaninc.com/ )

Quote:

Do NOT change the secondary clutch to adjust engine rpm.

I’ve seen too many people increase the pre-tension on their secondary to bring up their engine rpm, myself included.

You are shooting yourself in the foot !!!!

It decreases the efficiency of transmission of power to the track while adversely affecting the ability of the secondary to keep the shift curve flat.

Once you have your rpm where you want it, you next job is to get it to shift out the way you want.

That’s the job of the secondary.

The combination of spring and helix is what determines this.

Multi-angle is what I prefer.

The secondary spring directly equates to side-force on the belt.

The idea is that the more side-force you have on the belt, the less efficient it is because of belt drag.

Yamaha Secondary pre-tension (wind) should be around 16-24 ft lbs.

What I try to do is get to the minimum side-force possible without slipping the belt in the secondary.

Too much side-force and the clutch will back-shift too fast and put you in too low of a ratio and over rev when you stab the throttle out of a corner.

Too little and it won’t back-shift fast enough and it will react sluggishly (bog) and you’ll loose rpm climbing hills or trying to maintain high speeds.

// Tom Hartman ( CEO and owner of: http://www.hartmaninc.com/ )

Last edited:

Throttle Junkie35

New member

Good post lasse. I do have to say, 50* seems to work very well with my set up, however I sometimes will wind it to 60* if running in deep or very wet snow conditions.

toydoc

Member

I walked you through a process to check "what" your driven is set at. You need a real number with LBS, not you sunk my battle ship numbers. If it's above your head fine. But don't drive people away from tuning and understanding clutching with what you think is Voo Doo.

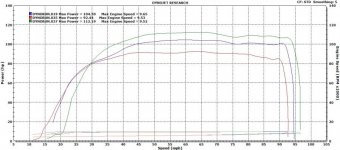

Here is a sled I tuned the secondary on. I'm not even sure what MFG the spring came from. I had to redrill holes in the driven to make it work.

It left my dyno and took 3rd in PS800, 4th PRO800 at Haydays. I don't think that guy you quoted took 1 or 2

Here is a sled I tuned the secondary on. I'm not even sure what MFG the spring came from. I had to redrill holes in the driven to make it work.

It left my dyno and took 3rd in PS800, 4th PRO800 at Haydays. I don't think that guy you quoted took 1 or 2

Attachments

I use to drill a new hole in the driven sheave and set the secondary tension to what I wanted.

I'd clamp vice grip on the outside top driven, use a fish scale and check it in LBS.

If I remember right, it like 14 Lbs of tension.

I check factory holes combos, log data of lbs @ A-2.. and so on.

From the data you find what factory setting is above and below my target 14lbs.

Good idea!

Good idea!

The Ski-Doo sleds measures the secondary clutch pre-tension in exactly that way with a fish scale.

Throttle Junkie35

New member

You are correct Doc, but I believe factory setting for the secondary on any year Exciter is 50* which is in fact a decent zero number (if your spring is decent) and assuming the rest of the clutch set up is in good shape. Going a step further is what you are suggesting which is a very cool and good idea which I never heard of before.......and I WILL be trying this winter.I walked you through a process to check "what" your driven is set at. You need a real number with LBS, not you sunk my battle ship numbers. If it's above your head fine. But don't drive people away from tuning and understanding clutching with what you think is Voo Doo.

Here is a sled I tuned the secondary on. I'm not even sure what MFG the spring came from. I had to redrill holes in the driven to make it work.

It left my dyno and took 3rd in PS800, 4th PRO800 at Haydays. I don't think that guy you quoted took 1 or 2

The problem I had with learning about clutching is that there is too much info on the net to decipher and adapt. Lots of stuff half way explained or explained as second hand, or just plain wrong.

I try not to muddy the waters for anyone nor do I claim to be a clutch expert, but I have found the best thing to do is only answer the question asked, because it will lead to more questions anyway. I still feel that unless you grab a box of primary and secondary tuning parts, spend a couple of weekends trying different set ups, learn what differences the pieces make to the clutching, that you will never really understand how to make atleast a seat of the pants, educated decision on how to get what you want out of clutching a sled.

So Doc,...what other tricks do you have up your sleeve??

toydoc

Member

Throttle Junkie you help alot of people with good answers. The more you help people, the more I remember and thats good. Thx

I may have taken the quote the wrong way from both of you. Sorry about that. It looked like when I posted what I do out of the norm, then the next post starts with quote "DO NOT adjust"??

Both of you and everyone working on old sleds with old clutching are going to run out of tuning parts for the primary. You only have so many weights, springs and rollers you can run / test. After that your forging your own weights or tuning with your driven (or both). Now your playing with your old driven. How may aftermarket helixs and springs did they make? They didn't have many when the Exciter was new even less now. So you now you look for stuff that may not have been made for it, but you can get it to work (cut down / re-drill holes..whatever it takes)

So how do you know what your even looking for? Lets use your sled as a example. I test belts first, soft, hard and top cog. Mine was always top cog soft. Your sled likes 50*, unless it's deep snow then 60*. Now you need a real number for each in lbs. From that you will have your area in lbs to work in. Now swap springs and retest pull in lbs or redrill holes move old spring. Take notes and go out and retest. You can use a bath scale, 2 wood blocks with a hole as a holding jig and jack to check your spring rates if you have to. Use SAME start point and end point of spring collapse, take notes on LBS of each spring. So at 3" gap scale shows 80lbs, at 2" gap 120lbs... so on. Test each spring.

Now you have GOOD notes on spring twist in LBS (back shift / up shift), and spring rate side pressure (belt slip). You know what spring you have and what it SHOULD do.

Then I make a grid on paper and go out and test:

Settings / Hole shot / mid / topend

Black spring 16lbs twist / good / ok / poor

I may have taken the quote the wrong way from both of you. Sorry about that. It looked like when I posted what I do out of the norm, then the next post starts with quote "DO NOT adjust"??

Both of you and everyone working on old sleds with old clutching are going to run out of tuning parts for the primary. You only have so many weights, springs and rollers you can run / test. After that your forging your own weights or tuning with your driven (or both). Now your playing with your old driven. How may aftermarket helixs and springs did they make? They didn't have many when the Exciter was new even less now. So you now you look for stuff that may not have been made for it, but you can get it to work (cut down / re-drill holes..whatever it takes)

So how do you know what your even looking for? Lets use your sled as a example. I test belts first, soft, hard and top cog. Mine was always top cog soft. Your sled likes 50*, unless it's deep snow then 60*. Now you need a real number for each in lbs. From that you will have your area in lbs to work in. Now swap springs and retest pull in lbs or redrill holes move old spring. Take notes and go out and retest. You can use a bath scale, 2 wood blocks with a hole as a holding jig and jack to check your spring rates if you have to. Use SAME start point and end point of spring collapse, take notes on LBS of each spring. So at 3" gap scale shows 80lbs, at 2" gap 120lbs... so on. Test each spring.

Now you have GOOD notes on spring twist in LBS (back shift / up shift), and spring rate side pressure (belt slip). You know what spring you have and what it SHOULD do.

Then I make a grid on paper and go out and test:

Settings / Hole shot / mid / topend

Black spring 16lbs twist / good / ok / poor

I may have taken the quote the wrong way from both of you.

Sorry about that.

It was not my intention to step on any toes.

I quoted just straight of what I read on a trusted site.

I'm really happy and grateful for all the help I can get from you Yamaha geeks

Last edited:

Throttle Junkie35

New member

Thanks for the complement Doc!!! You have always given me good advice and answers as well. I always appreciate it.

I guess what I was getting at is that for most guys running these older sleds a stock setting is a good place to start since I have seen many of these Exciters with miss matched "make it work" parts on them as guys try to keep these things running over the years. So you never really know what your working with unless you can actually see it in person...or have really good pics of what they have. That is why I was using battleship numbers. LOL. I like the idea of drilling new holes to get the correct tension. I never thought about that.

I figure a stock setting is a good idea and will give you a place to start from on an old sled. It will most likely tell you if you have anything else in the clutching that is wrong or needs attention.

You are correct as far as tuning parts. There are not many springs, helix's or weights out there for the YPZ. I have come across some aftermarket parts in my time in playing with these sleds though. The coolest being the 49-39 RPC helix's. These things pull out of the hole like no other. That is actually the only aftermarket helix that I am aware of for those secondaries. I also came across PSI clutch weights for PSI single pipe. They are just modified 84m's. They are very heavy.

I guess what I was getting at is that for most guys running these older sleds a stock setting is a good place to start since I have seen many of these Exciters with miss matched "make it work" parts on them as guys try to keep these things running over the years. So you never really know what your working with unless you can actually see it in person...or have really good pics of what they have. That is why I was using battleship numbers. LOL. I like the idea of drilling new holes to get the correct tension. I never thought about that.

I figure a stock setting is a good idea and will give you a place to start from on an old sled. It will most likely tell you if you have anything else in the clutching that is wrong or needs attention.

You are correct as far as tuning parts. There are not many springs, helix's or weights out there for the YPZ. I have come across some aftermarket parts in my time in playing with these sleds though. The coolest being the 49-39 RPC helix's. These things pull out of the hole like no other. That is actually the only aftermarket helix that I am aware of for those secondaries. I also came across PSI clutch weights for PSI single pipe. They are just modified 84m's. They are very heavy.

Is there a list of the different Yamaha OE helixes to YPZ secondary clutch ?There are not many springs, helix's or weights out there for the YPZ clutch system.

I have come across some aftermarket parts in my time in playing with these sleds though.

The coolest being the 49-39 RPC helix's.

These things pull out of the hole like no other.

That is actually the only aftermarket helix that I am aware of for those secondaries.

Throttle Junkie35

New member

Now that I think of it, I know I have a straight 51* cut helix and I remember talking with Yamaha Nutz about several other aftermarket helix's too. As far as stock goes, I know there is a 39* 42* 45* 47* and 45-39* Im sure there is more. I also know Hauck still makes some custom Helix's as well, but I dont know what they are spec wise.

Black Bear

New member

Definitely got more than i was expecting from this thread. I appreciate all of the knowledge that is being shared. I would have participated (asked more questions) in the discussion but i have been busy working on the sled. Its an 89 that I picked up earlier in the year for $75.00 with a dead cylinder. After cleaning at least 10 lbs of critter refuse from everywhere imaginable I have now have completed going through the various systems on the sled. I had another motor that was ready to go so that piece of the work was easy. Once cleaned up the sled was in near perfect shape. Anyhow took it out to my test strip (200 yards) the other day (Central Massachusetts 60 degrees F) made sure i was aligned, deflection (one washer between sheaves) was good and had a new belt 89X-17641-01. I started with the secondary in A2, Needle clip in the 2nd position sled response was a little sluggish. I moved the secondary setting to B-3 and the sled is absolute beast on the low end. I suspect it might spin the track to easy once the snow flies but for now it is fun on the grass slope.

I probably wont need to drill new holes but the discussion certainly helped me understand a little better. Thanks to all!!

I probably wont need to drill new holes but the discussion certainly helped me understand a little better. Thanks to all!!

Throttle Junkie35

New member

B-3 is 90*....seems like alot of tension. What spring and helix are you running??