rubbersidedown

New member

Yesterday was my first ride with a lot of changes over the summer. Dropped in a 1600 mile motor complete carbs exhaust powervalves servo cdi box all too eliminate odd codes that were hard to track. Fixed all bad spots in harness. Put on a used primary with heel clickers and the secondary that came with it I don't know the helix angle. I have 8 tooth anti ratchets 121 m-10 stretched to 144 tip up rails 7" rear wheels. 25 upper gear with I think is a 39 bottom. Reverse is out if a 98 TXC. Starts easy just hit key. Idles fine. Hit throttle and doesn't really spin track just excels but about 50 mph it just falls flat. Pin it and nothing slowly climbs to 60 mph and never passes 7000. Full throttle doesn't seem to bog just doesn't seem to do anything. Not seeing unburned fuel. plugs look maybe a little rich but not bad. Was going to put factory clutches back on to test but looking for other opinions. Thanks Scott

Last edited:

drew24

New member

Sounds clutch related. Put factory clutches back on and try it. If it is the problem you should be able to tune the heel clickers in once you know for sure that's the problem. Also not sure why a 25t top gear. Might want to try 22t especially with the 144 track. And make sure track is not tight. M10 has to be ran a lot looser than most skids. Likely have a combination of things going on.

Last edited:

rubbersidedown

New member

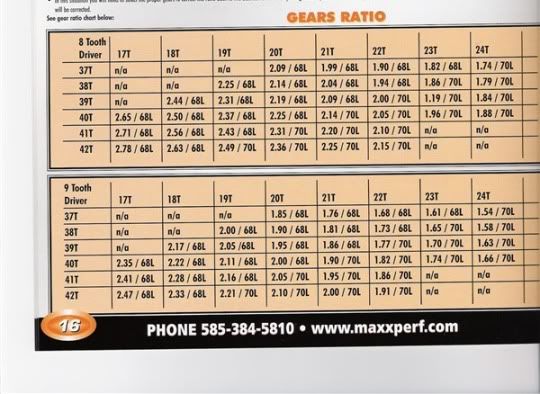

25 top was to get me back closer to stock gear ratio after switching too 8 tooth vrs 9 tooth drivers and bottom reverse gear from XTC. Right now my speedo reads within 1-2 mph of my gps. I will try clutches for sure thanks

drew24

New member

Gotcha. I forgot it said you had 8t drivers.25 top was to get me back closer to stock gear ratio after switching too 8 tooth vrs 9 tooth drivers and bottom reverse gear from XTC. Right now my speedo reads within 1-2 mph of my gps. I will try clutches for sure thanks

rubbersidedown

New member

I put the clutches back in that were on the sled when I bought it with 2200 miles. primary looks like stock, secondary has a Hauck helix I didn't write it down thought I could remember it but I think green spring hole 6 42/38. runs out fine down driveway but will try on trail tomorrow. I have noticed with this clutch since day one when it is on a stand that the track will always spin at idle but when on the ground never moves. There is 13,000 miles on the sled now so at least 12,000 on clutches that is why I wanted to change. I can't find anyone in the area to rebuild or build me anew clutch. My local dealer won't mess with it

super1c

Super Moderator

With that 144 you would want to gear down if running 9 tooth drivers but when changing to 8tooth it does it automatic. That is how it was explained to me when I 144'd mine. That's with stock gearing so I would try and bring that 25 back to 22 and try. That 25 is big!

super1c

Super Moderator

As far a track spinning in the air that's belt deflection and it should just creep when off the ground but not move when on ground

A couple of bucks

VIP Member

And with bringing it back to 22, you should gain RPM.

A couple of bucks

VIP Member

A 22/39 combo w/ 8 tooth drivers puts you at a 2:1 ratio. Not a huge amount of top end. But it does make for a good "jack rabbit", fence line to fence line sled.

Youllbe2nd

New member

I wonder if that is too much gear

Sent from my E6560C using Tapatalk

Sent from my E6560C using Tapatalk

Mac

Member

rubbersidedown

New member

Well I put on 135 on yesterday with old clutches and the rpms climbed a little to around7000 but speed was top at 62. has nothing after half throttle. I pin it and just nothing no bog just nothing. I ran this same setup last year and was fine with a 136 and seemed fine for the 1200 miles after I on the 144 but at the end of the season the two 150 ish mile loops I noticed terrible mileage. I always got 10-12 normally but 8.6 gallons for 56 miles on groomed trails no off trail is 6.5 not good. I took it to a dealer to have it looked at so I could ride the following weekend. I was getting a power valve code so I unplugged the servo because it would only twitch or rotate the opposite direction and a cable would come off. I thought that was my problem so they should be able to fix. I was then getting a tps code also. The dealer said that it was hard to pinpoint the problem it could be servo motor cdi box maybe even a voltage problem that my gps was drawing too much current. They did a compression test and said one side was low I think it was 125 125 110. That is when I took sled home I know that vipers run a lower compression on one if the dealer doesn't know this they can't trouble shoot my issues. After some thought I decided with 13,000 miles on the sled it was better to just put in a used motor and found a complete 1600 mile motor carbs cdi powervalves servo and heelclickers with secondary. When I did the replacement I found a rub though below the cdi box at the foot well and repaired. I get no codes now and my mileage has been 8-9. Now I am unsure what to do or where to look. It is not clutching. I am going to do a compression test today.

Hammer Down

Member

My 01 is 120 On all three. I bet the 110 cylinder is your issue.' It's also more than the "within' 10%" rule that is quoted repeatedly on TY.

BornYamaha

Member

Have you tested the power valves and made sure they are free and adjusted correctly?

Sent from my SM-G920V using Tapatalk

Sent from my SM-G920V using Tapatalk

rubbersidedown

New member

Yes power valves are clean and adjusted. I even took them out to be sure when I put old clutches in. When I had first put in the 8t drivers the 22 top was a rocket to start but was just screaming at 70 so I decided to re gear to get closer to stock. At the end of last season with the old motor when I had power valves unplugged it had plenty of top but was very flat on the bottom. I assume because they were open.

Don't know why the servo would turn the wrong way unless the cables are on wrong maybe? How did you adjust the cables? Idle the motor down to 900 RPM or do you have a servo plug in with the 12 volt wire set. With the sled on the stand did you ever pull the servo cover and watch what it is doing when you use the throttle?

also a twitching servo is a possible sign that the cables are to tight.

also a twitching servo is a possible sign that the cables are to tight.

rubbersidedown

New member

servo was twitching and turning the opposite way because of a rub through in the cdi harness. That was also causing my tps code. Now that is all fine. I did a compression test PTO 100 CENTER 113 MAG 115. I decided to pull carbs and check jets because someone said that it may be jetted to fat for pipes possibly. I have a white coating on all of the brass parts nothing else,odd. I also can't read the numbers on the jets. Will get a magnifying glass tomorrow. There was also some possible gunk in the center main. If I can't read the numbers I will put the mains in from my old carbs and see what happens. Could rust build up on the flywheel and cause a weak spark at higher rpms?

servo was twitching and turning the opposite way because of a rub through in the cdi harness. That was also causing my tps code. Now that is all fine. I did a compression test PTO 100 CENTER 113 MAG 115. I decided to pull carbs and check jets because someone said that it may be jetted to fat for pipes possibly. I have a white coating on all of the brass parts nothing else,odd. I also can't read the numbers on the jets. Will get a magnifying glass tomorrow. There was also some possible gunk in the center main. If I can't read the numbers I will put the mains in from my old carbs and see what happens. Could rust build up on the flywheel and cause a weak spark at higher rpms?

When you pull those carbs apart, remove the float needle/seat. There are "top Hat" shaped filters under the seat. These hidden filters can partially or fully plug the fuel flow into the float bowl and cause all kinds of issues. The one time I saw these plugged on a Yamaha was when there was white in the float bowl and on the brass...the filters also had a white paint like coating. I remove these filters on all my Yamahas.

Also the compression on an SRX should be the same all the way across...that PTO cylinder is outside of the max 10% difference between cylinders.

Usually a rusty flywheel/stator create a hard start issue as well.

JM.02c

vipers have staggered compression and it is perfectly normal to have the pto lower then the center and mag as the dome in the head is larger then that of the center and mag cylinders, theres nothing wrong with the compression.

rubbersidedown

New member

I always clean those top hat filters and clean. I will do it again since it is out of sled again. I didn't realize you could eliminate them.