Manuka

New member

- Joined

- Jan 27, 2005

- Messages

- 16

My friend has been having problems with the clutch on his 95' Phazer.

The clutch does not release after riding for a short period of time. When he first starts it up it runs great but after some riding the clutch just gets sticky and doesnt fully release the belt.

So we took the clutch apart and cleaned it. Forgive for not knowing the techinical terms so bear with me. There are three white plastic spacers or something that the clutch rides against when it is moving in and out. We removed the spacers and cleaned them. With the spacers out the clutch moved freely up and down. Once everything was clean we reassembled it seemed a bit sticky and it seemed the resistance was coming from the plastic spacers, bushing or what ever they are.

We bought the plastic pieces and will be installing them tonight. Hopefully that will do it.

Seems that the plastic would wear over time and make it loose as opposed to tight?

The springs have also been replaced.

Has anyone had this problem or could you guys suggest some other possible problems to look for?

Have a trip next week and would like to get things fixed up before we go.I would really appreciate your help

Thanks,

Mike

The clutch does not release after riding for a short period of time. When he first starts it up it runs great but after some riding the clutch just gets sticky and doesnt fully release the belt.

So we took the clutch apart and cleaned it. Forgive for not knowing the techinical terms so bear with me. There are three white plastic spacers or something that the clutch rides against when it is moving in and out. We removed the spacers and cleaned them. With the spacers out the clutch moved freely up and down. Once everything was clean we reassembled it seemed a bit sticky and it seemed the resistance was coming from the plastic spacers, bushing or what ever they are.

We bought the plastic pieces and will be installing them tonight. Hopefully that will do it.

Seems that the plastic would wear over time and make it loose as opposed to tight?

The springs have also been replaced.

Has anyone had this problem or could you guys suggest some other possible problems to look for?

Have a trip next week and would like to get things fixed up before we go.I would really appreciate your help

Thanks,

Mike

yamyrider

Active member

if there has not been any work done to the clutches the bushings are a good place to start. Make sure weights move freely. You will also ahve to make sure clutches are aligned properly, center to center and offset.

Mtnviper

Member

Been there done that, and I have a fix for it. The problem is the white nylon bushings warp when hot and bind.

The fix is to update your YXR clutch to YVX spider bushings used on all current Yamaha models. What you do is replace the 3 white bushings with 6 smaller YVX black spider bushings.

Parts required

6 part # 8BW-17653-00-00 YVX spider bushings (used in Viper, SRX, SXR, RX-1)

3 part # 91609-50032-00 YVX spider bushing roll pins

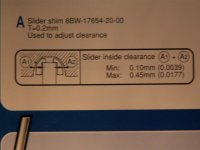

Spider bushing shims #8BW-17654-20-00 if required. Mine didn't require any of these. These shims are used to adjust spider to moveable sheave clearance if it is to loose.

Any bushings, rollers, pins, weights, etc that show signs of wear while you have the clutch apart.

Here kind of the Reader's Digest version of whats done.

Tools required

Clutch puller

Clutch break down tool (grunt tool) used to remove the spider from the fixed sheave.

drill press

3/32", 3/16", no 10 and no 9 drill bits.

3/16" bit is .1875"

no 10 bit is .1935"

no. 9 bit is .1960"

fine tooth file, and fine sand paper (used to file the outside of the new spider bushings for proper clearance to the moveable sheave.

Basicly what you are doing is drilling your spider to accept the roll pins that locate the new bushings. Try a 3/16" hole first, if the pin dosn't want to press in, then go to a number 10 or 9 drill bit. Care must be taken when drilling the spider to make sure the hole is centered, the YVX spider is slightly thicker in this area then the YXR spider. I used the bushing and a pair of measuring calipers to locate the hole. I also drilled in half way from each side of the spider to help make sure things are centered.

Most likely you will have to file down the "high spots" on the outside of the bushing, if the spider fits to tightly in the moveable sheave.

I do one arm at time and bolt the cover to the moveable sheave to keep things square while checking/adjusting spider to sheave clearance. Spec for clearance is .10mm to .45mm. If it to loose (greater than .45mm) then the shims listed above can be used behind the spider bushing to take up the extra clearance. When fitting the bushing to sheave, high spots will leave witness marks on the bushing. It's these areas where you would file for more clearance if needed.

When all 3 arms are fitted/clearanced correctly, you should be able to bolt the cover on and have the sheave move back and forth freely with no binding.

Basicly what your doing is making your YXR clutch into a YVX clutch. It makes a huge difference in performance, no more binding. I actually had to shim the primary spring to bring the rpms up when done. This is because the clutch shifted out much smoother and more aggressive! (a good thing).

I've been thinking about writing a more detailed step by step proceedure, with pics and part numbers. To see if Mr Sled would be interested in having it for the tech pages, but I havn't quite got around to it yet. With no snow around here maybe I'll get to it sooner than I thought.

The fix is to update your YXR clutch to YVX spider bushings used on all current Yamaha models. What you do is replace the 3 white bushings with 6 smaller YVX black spider bushings.

Parts required

6 part # 8BW-17653-00-00 YVX spider bushings (used in Viper, SRX, SXR, RX-1)

3 part # 91609-50032-00 YVX spider bushing roll pins

Spider bushing shims #8BW-17654-20-00 if required. Mine didn't require any of these. These shims are used to adjust spider to moveable sheave clearance if it is to loose.

Any bushings, rollers, pins, weights, etc that show signs of wear while you have the clutch apart.

Here kind of the Reader's Digest version of whats done.

Tools required

Clutch puller

Clutch break down tool (grunt tool) used to remove the spider from the fixed sheave.

drill press

3/32", 3/16", no 10 and no 9 drill bits.

3/16" bit is .1875"

no 10 bit is .1935"

no. 9 bit is .1960"

fine tooth file, and fine sand paper (used to file the outside of the new spider bushings for proper clearance to the moveable sheave.

Basicly what you are doing is drilling your spider to accept the roll pins that locate the new bushings. Try a 3/16" hole first, if the pin dosn't want to press in, then go to a number 10 or 9 drill bit. Care must be taken when drilling the spider to make sure the hole is centered, the YVX spider is slightly thicker in this area then the YXR spider. I used the bushing and a pair of measuring calipers to locate the hole. I also drilled in half way from each side of the spider to help make sure things are centered.

Most likely you will have to file down the "high spots" on the outside of the bushing, if the spider fits to tightly in the moveable sheave.

I do one arm at time and bolt the cover to the moveable sheave to keep things square while checking/adjusting spider to sheave clearance. Spec for clearance is .10mm to .45mm. If it to loose (greater than .45mm) then the shims listed above can be used behind the spider bushing to take up the extra clearance. When fitting the bushing to sheave, high spots will leave witness marks on the bushing. It's these areas where you would file for more clearance if needed.

When all 3 arms are fitted/clearanced correctly, you should be able to bolt the cover on and have the sheave move back and forth freely with no binding.

Basicly what your doing is making your YXR clutch into a YVX clutch. It makes a huge difference in performance, no more binding. I actually had to shim the primary spring to bring the rpms up when done. This is because the clutch shifted out much smoother and more aggressive! (a good thing).

I've been thinking about writing a more detailed step by step proceedure, with pics and part numbers. To see if Mr Sled would be interested in having it for the tech pages, but I havn't quite got around to it yet. With no snow around here maybe I'll get to it sooner than I thought.

Last edited:

Outstanding reply Mtn viper....

Sweet!! Its great to see informative post in the tech section!!

Nice job Mtnviper........

Sweet!! Its great to see informative post in the tech section!!

Nice job Mtnviper........

Mtnviper

Member

Thanks mrviper700, this is one of those problems I fought on my 91 exciter and then on the 92 Phazer. I tried just about everything trying to make those white nylon bushings work. It would be ok for a couple rides, then the primary would start binding again. Mountain riding makes it even worse. As soon as I converted the clutch to the new style bushings, binding is gone no matter how hard I ride it!

I believe this is why Yamaha went to the new style bushing in the YVX clutch.

I believe this is why Yamaha went to the new style bushing in the YVX clutch.

Manuka

New member

- Joined

- Jan 27, 2005

- Messages

- 16

Thanks for the input, we replaced the bushings and it seems to be running great. Or at least for know. Can't believe those bushings were 15 bucks a piece.

Thanks again

Mike

Thanks again

Mike

Mtnviper

Member

Here are some pic's for doing the YXR to YVX mod. ( I finally bought a digital camera!)

The primary difference between the YXR and YVX spider's, is the casting where the pin goes through on the YVX is thicker. This can be seen in some of the pic's. I used a YVX spider in some of the pics, for photo purposes.

If you are going to build a mod motor, then you may want to use a YVX spider, as they are stronger. For stock Phazer and Exciter motor's the YXR spider will work.

The primary difference between the YXR and YVX spider's, is the casting where the pin goes through on the YVX is thicker. This can be seen in some of the pic's. I used a YVX spider in some of the pics, for photo purposes.

If you are going to build a mod motor, then you may want to use a YVX spider, as they are stronger. For stock Phazer and Exciter motor's the YXR spider will work.

Attachments

Last edited: