Just curious I see a lot of talk of 'properly set up' and 'its all in the tuning' what are you guys using for tools and data to do this?

Engine:

My thought process is to jet heavy and reduce with a tempaflow based on EGT, and plug wash. I don't have the skills or ambition to re-jet on a snowmobile trip so it has to involve some sort of compensation device to give me the adjustability.

Clutch:

Check RPMs, what about clutch temps you use a infared temp gauge?

Suspension:

No idea what to tune for here, I have it set up for comfort and enough transfer to pull the tension off the front shocks but the skies will still be glazing the surface.

Clue me in guys! Normally we don't get enough snow where i can do it at home, make some adjustments, go back out, etc. I usually have to drive and once i get there I want easy adjustment. Thanks!

Engine:

My thought process is to jet heavy and reduce with a tempaflow based on EGT, and plug wash. I don't have the skills or ambition to re-jet on a snowmobile trip so it has to involve some sort of compensation device to give me the adjustability.

Clutch:

Check RPMs, what about clutch temps you use a infared temp gauge?

Suspension:

No idea what to tune for here, I have it set up for comfort and enough transfer to pull the tension off the front shocks but the skies will still be glazing the surface.

Clue me in guys! Normally we don't get enough snow where i can do it at home, make some adjustments, go back out, etc. I usually have to drive and once i get there I want easy adjustment. Thanks!

either timers if your lucky or even by your speedo in a given marked off distance can help you to tune. Clutching can be done out on the trail if you carry basic tools and have a feel for changing stuff. I have even changed needle settings out on the trail, but if you take the time to set up the sled at the beginning of the season on 1 test and tune day at a freinds field or whatever, you can pretty much be set up decent all year as far as suspension, clutching and basic jetting.

I would work on your jetting first, but I wouldnt use a egt and a tempablow to set it up, you have to read the spark plugs and look at the top of the piston to get in the ballpark first. You see the perfect mixture may be lower or higher then what your egt will be showing, the egt is basicly a tool to "monitor the set up" after you baseline it with good ol fashion tuning and reading plugs and piston wash. What I do to guys when they come here to tune a sled is I put a peice of duct tape over the egt till we read the plugs and piston tops, then when we get the correct mixture, they can use the numbers displayed to monitor the set up. I have had alot of guys say wow, thats 2-300 degrees hotter or whatever then where I was running it at, and that means they were off on thier jetting.

After that is done I would go to suspension, get the sled to squat somewhat when it leaves the hole from a stop, it should just carry the ski's about a couple inchs off the snow. This is done by the rear transfer rods gap, the rear fra adjuster adjustment, and the rear spring tension. the front limiter straps will have alot of say in the amount of ski lift you are comfortable with, find a happy balance of adequate ski pressure and good out of the hole traction. After all that, do the clutching dead last, only because the motor has to make the proper power by having the correct fuel mixture in it and the suspension will dictate how much power you can apply to the ground, now you want your clutching to be what ever rpm range your sled is designed for. If you add pipes oe whatever the clutching is what dictates the rpm of the engine. It all depends on what clutching you use as to how to tune it, but basic rules are the front clutch controls your engine rpm, the back clutch controls the delivery of the shift. A hot clutch is a slipping clutch, a nice luke warm set up is what your after, you can use the infared indicators, they work slick, or you can do the touch test, if its too hot, you will not be able to have your fingers on the sheave face for more then about 2-3 seconds. When you get to optimium set up and the clutchs are hanging onto the belt and your rpms are perfect, youll be able to lay your whole hand on the sheaves and they will be luke warm to the touch. Dont let this all intimidate ya from trying it, its only a days worth of tuning to get where you need to be for a decent set up that will work good for ya.

I would work on your jetting first, but I wouldnt use a egt and a tempablow to set it up, you have to read the spark plugs and look at the top of the piston to get in the ballpark first. You see the perfect mixture may be lower or higher then what your egt will be showing, the egt is basicly a tool to "monitor the set up" after you baseline it with good ol fashion tuning and reading plugs and piston wash. What I do to guys when they come here to tune a sled is I put a peice of duct tape over the egt till we read the plugs and piston tops, then when we get the correct mixture, they can use the numbers displayed to monitor the set up. I have had alot of guys say wow, thats 2-300 degrees hotter or whatever then where I was running it at, and that means they were off on thier jetting.

After that is done I would go to suspension, get the sled to squat somewhat when it leaves the hole from a stop, it should just carry the ski's about a couple inchs off the snow. This is done by the rear transfer rods gap, the rear fra adjuster adjustment, and the rear spring tension. the front limiter straps will have alot of say in the amount of ski lift you are comfortable with, find a happy balance of adequate ski pressure and good out of the hole traction. After all that, do the clutching dead last, only because the motor has to make the proper power by having the correct fuel mixture in it and the suspension will dictate how much power you can apply to the ground, now you want your clutching to be what ever rpm range your sled is designed for. If you add pipes oe whatever the clutching is what dictates the rpm of the engine. It all depends on what clutching you use as to how to tune it, but basic rules are the front clutch controls your engine rpm, the back clutch controls the delivery of the shift. A hot clutch is a slipping clutch, a nice luke warm set up is what your after, you can use the infared indicators, they work slick, or you can do the touch test, if its too hot, you will not be able to have your fingers on the sheave face for more then about 2-3 seconds. When you get to optimium set up and the clutchs are hanging onto the belt and your rpms are perfect, youll be able to lay your whole hand on the sheaves and they will be luke warm to the touch. Dont let this all intimidate ya from trying it, its only a days worth of tuning to get where you need to be for a decent set up that will work good for ya.

Last edited:

That is awesome and helpful.

One scenario, I just drove 300 miles to get to snow, I set up the sled as best as I could in the shop, get her out and its rich as heck. What do I do? Pulling the carbs and swapping jets is just way to intimdating and time consuming for me and my skill level, as well as not having a nice shop (if were renting a cabin or something) and the right tools. I can do it fine when its sitting in my shop but not on the trail. Are there any options or do I just plan a extra day to get the sled dialed in?

I take it your not a fan of any carb compensation device, is the engine forgiving enough that a proper set up at 20 degrees will still be safe at -20 on the way home some unexpected night?

One scenario, I just drove 300 miles to get to snow, I set up the sled as best as I could in the shop, get her out and its rich as heck. What do I do? Pulling the carbs and swapping jets is just way to intimdating and time consuming for me and my skill level, as well as not having a nice shop (if were renting a cabin or something) and the right tools. I can do it fine when its sitting in my shop but not on the trail. Are there any options or do I just plan a extra day to get the sled dialed in?

I take it your not a fan of any carb compensation device, is the engine forgiving enough that a proper set up at 20 degrees will still be safe at -20 on the way home some unexpected night?

ya, Kinger find someone around you that will let you come play with sled in a field or something, that day of tuning will be all it takes if you do it in the right order. I understand the drive to find snow, I have rarely gotten to ride from my house here, ohio just doesnt get snow like we used to.

As far as carbs go, once you get them where they need to be there is some forgiveness in them if you set them up that way, and yes, I kinda hate tempablows, I have fixed so many sleds that these things have ruined. You really dont get much better mileage with one versus without one if you dial in the carbs and clutching, yes........ clutching, as jetting and clutching go hand in hand for fuel mileage.

I will post some jetting advice for you when I get a chance, like how to read plugs and piston tops, and what to look for so.

As far as carbs go, once you get them where they need to be there is some forgiveness in them if you set them up that way, and yes, I kinda hate tempablows, I have fixed so many sleds that these things have ruined. You really dont get much better mileage with one versus without one if you dial in the carbs and clutching, yes........ clutching, as jetting and clutching go hand in hand for fuel mileage.

I will post some jetting advice for you when I get a chance, like how to read plugs and piston tops, and what to look for so.

YAMMIEGOD3:16

Active member

SEAT OF MY PANTS. OR YOUR PANTS FOR THAT MATTER !!! 3:16 (tony)

What I did last year was run at like 6000, 6500, 7000, 7500, 8000, 8500 and held it at each rpm as best I could then hit the kill switch and coasted to a stop, then check plugs. Never really been able to look at wash. Better invest in a flex light or something.

What I did was when I found a error I would adjust with the tempaflow (rich or lean you have some adjustment) and get it dialed in. I did find that tuning for 6000 rpm didn't match 8000 rpm when the timing spike would hit.

What I did was when I found a error I would adjust with the tempaflow (rich or lean you have some adjustment) and get it dialed in. I did find that tuning for 6000 rpm didn't match 8000 rpm when the timing spike would hit.

ya, get a bend a lite or flex light so you can look at piston tops, your gonna use it!!

you dont check the wash at each 100-500 interval, you see the carb circuits over lap each other, what you want to do is to start with your idle and low speed circuit, this is the pilot jet and your fuel screws. Get the sled to idle decently and not hang up the idle on returning from a rev.

Next try the sled out in the field, does it bog when you smack the gas? does it cough/ or does it rev up smoothly for about 50 feet or so out from your stop.

Once you have that done, your ready to move to midrange. this is the needle circuit and where 90 percent of all guys burn their sleds down! you want to take the sled for a half throttle run and do nothing but run it for about 350feet out at half throttle only, reach over with your left hand and hit the kill swithc while you continue to keep it at half throttle, sled will coast to a stop and you look at piston tops and plugs for correct mixture. Adjust needle position as per wash and plug coloring.

Lastly your ready to make a run for about 500-600ft at wide open, same kill switch thing as before, and same check of plugs and piston tops. This is the main jet circuit your working on now.

you dont check the wash at each 100-500 interval, you see the carb circuits over lap each other, what you want to do is to start with your idle and low speed circuit, this is the pilot jet and your fuel screws. Get the sled to idle decently and not hang up the idle on returning from a rev.

Next try the sled out in the field, does it bog when you smack the gas? does it cough/ or does it rev up smoothly for about 50 feet or so out from your stop.

Once you have that done, your ready to move to midrange. this is the needle circuit and where 90 percent of all guys burn their sleds down! you want to take the sled for a half throttle run and do nothing but run it for about 350feet out at half throttle only, reach over with your left hand and hit the kill swithc while you continue to keep it at half throttle, sled will coast to a stop and you look at piston tops and plugs for correct mixture. Adjust needle position as per wash and plug coloring.

Lastly your ready to make a run for about 500-600ft at wide open, same kill switch thing as before, and same check of plugs and piston tops. This is the main jet circuit your working on now.

you can get a led bendalight at lowes by mag lite for about 5 to 10 bucks. You can use my way, lean on it till it sqweeeks, then try again. LOL Better yet to do it Don's way. I was always told to set it with the tempa flow unhooked, that way you are safe and it runs more consistant. Maxdlx

Last edited:

Hey Paul thats how us old timers did it, they always run the best right when they start to blow.....LOL!! Just go back up 1 size and it rips!!!!

KIDDING!!

KIDDING!!

shortstop20

New member

- Joined

- Mar 6, 2005

- Messages

- 1,583

- Age

- 39

- Location

- Stickney, South Dakota

- Website

- www.snowmobilefanatics.net

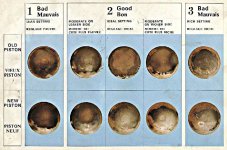

Mr. Viper can you explain what piston wash should look like?? I've researched a little on the subject and I hear some say you want 1/4"-3/8" wash and I've heard some say you want pinky fingernail sized spots near the exhaust port if I remember correctly. It seems there different info out there. I'm almost happy with the jetting on my sled. I bought some shims(.10, .20, and .30) for N2oiroc a while back that I'm going to try out this year. Plugs look like I may be able to go a little leaner yet but I want to look at the piston wash to verify my reading of the plugs. Does Napa sell bend a light's?? That's the easiest place for me to get one.

RJH

New member

Yes – the tempraflow works in one direction then back to a base point – it won’t go beyond that base point. Also - Running at 6000 rpm – you are off the main jet and jetting on the needle.

Get all that aftermarket stuff off it and jet to what the manual says –good enough for safe fast trail riding. If you are a mountain rider - maybe then.

Clutch – if you can’t touch it with your hand and hold it there – it’s too hot.

Suspension – test and tune. Don’t go too far beyond stock, with aftermarket – the track will not stay at the correct tension.

If you just get out a bit - sticking with aftermarket cosmetic stuff only would be good. You got so much stuff – it will be hard to run nice.

Piston wash – probably all that have suggested is correct – each engine style has its own wash. Our winning shifter kart with a 125 cc 43 HP, 13,000 rpm 6 speed had no piston wash it was so efficient, just a very slight rim around the entire piston that only repetitious looking could identify. It wouldn’t seize either – just detonate the piston rim if too lean. Sold

Our Yamaha Blaster has black around the rim – middle clean – low efficiency and our...

YZ125 (sold had all black with 2 little white tits on the rim of the piston – intake side. Good efficiency.

P.S.- the above picture post - would look like pistons from our Blaster or Phazer

Get all that aftermarket stuff off it and jet to what the manual says –good enough for safe fast trail riding. If you are a mountain rider - maybe then.

Clutch – if you can’t touch it with your hand and hold it there – it’s too hot.

Suspension – test and tune. Don’t go too far beyond stock, with aftermarket – the track will not stay at the correct tension.

If you just get out a bit - sticking with aftermarket cosmetic stuff only would be good. You got so much stuff – it will be hard to run nice.

Piston wash – probably all that have suggested is correct – each engine style has its own wash. Our winning shifter kart with a 125 cc 43 HP, 13,000 rpm 6 speed had no piston wash it was so efficient, just a very slight rim around the entire piston that only repetitious looking could identify. It wouldn’t seize either – just detonate the piston rim if too lean. Sold

Our Yamaha Blaster has black around the rim – middle clean – low efficiency and our...

YZ125 (sold had all black with 2 little white tits on the rim of the piston – intake side. Good efficiency.

P.S.- the above picture post - would look like pistons from our Blaster or Phazer

Last edited:

nightmanx1

New member

iif you know an aircraft Mech they might have a borescope to look in the sparkplug hole.

Alright so what I'm hearing is that once your dialed in for your mods, no more adjustment is needed. Therefore a tempaflow or variflow is not needed.

Everyone agree on that?

I get worried you at the mercy of mother nature and a trip could start out at 20 degrees and plumit to -20 by the time your heading home 100 miles away in the middle of BFE

Everyone agree on that?

I get worried you at the mercy of mother nature and a trip could start out at 20 degrees and plumit to -20 by the time your heading home 100 miles away in the middle of BFE