bluemonster1

LIFE MEMBER ONLY ONCE!!!

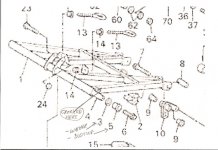

My w-arm on the 2002 SRX on the outside left upper where it is welded to the upper shaft,( this is where the threaded shaft runs thru into both sides of tunnel) has cracked just below the welding joint.Seems like one part of the weld is still intact.Should be no problem to take off and get it welded up again.

Also there is a lot of play where the top part of the arm(circular)runs between the tunnel sides.I'd say around 1/2" if I slide the arm to one side.All I can see is maybe the edge of the washer or the edge of the bushing after the length of the actual top of the w-arm.That would make it 1/4" play on both ends.This can't be normal.According to the Yamaha Parts diagram it shows a washer and then a bushing on each end which should bring everything tight against the tunnel on each side...right.Between the thickness of the washer and the bushing,what is the total thickness of both.

Also there is a lot of play where the top part of the arm(circular)runs between the tunnel sides.I'd say around 1/2" if I slide the arm to one side.All I can see is maybe the edge of the washer or the edge of the bushing after the length of the actual top of the w-arm.That would make it 1/4" play on both ends.This can't be normal.According to the Yamaha Parts diagram it shows a washer and then a bushing on each end which should bring everything tight against the tunnel on each side...right.Between the thickness of the washer and the bushing,what is the total thickness of both.

Attachments

2001SRX=Fast

New member

reforce and reweld kind of a big job.

Exciterfan

Member

You don't want the W-arm tight against the inside of the tunnel as that will prevent it from rotating when you compress the skid frame. That would hinder your suspension from doing its job.

However, I don't think you should have a 1/4" on both sides???

However, I don't think you should have a 1/4" on both sides???

sxviper32

New member

daman

New member

There will be some play in there,all thats in there is the washer and bush

make sure there is a washer on each side

make sure there is a washer on each side

bluemonster1

LIFE MEMBER ONLY ONCE!!!

Not working today because it is to cold out.Got right into tearing SRX 's suspension components...w-arm to be exact.Thought there was one crack in the arm,but once I got it out...see 3 cracks in the arm....wow.And as for the washer and bushings that should be there...there was none.Tons of play in this thing for sure.Whoever had this sled before sure didn't care or do proper maintenance that's for sure.That's why I'll spend $100's of dollars to get it back up to parr.But it's fun and a learning experience.I am a little pissed off of course,but when you buy a used sled you never know what you are really getting.My SXR really didn't have these problems.Maybe because the SRX is a beast and people ride them like they won't break

I went and ordered a new a-arm ,washers,upper bushings and lower bushings.Some $350.00 later of course,but I'll feel better.This is a major component of the suspension.Can't have all that play in there.

In the summer I'll get the old a-arm re-welded and re-inforced and keep as a spare part for the future.

Got my Tach today from UPS.Won't be able to see if it works until I get my clutch align. tool in to align clutches.Then back go on the carbs,air box and pipes.Then cross my finger I will get a rpm reading.

I don't know,but it is never ending working to get sleds up to parr.But at least I will do it properly and feel assured.

I went and ordered a new a-arm ,washers,upper bushings and lower bushings.Some $350.00 later of course,but I'll feel better.This is a major component of the suspension.Can't have all that play in there.

In the summer I'll get the old a-arm re-welded and re-inforced and keep as a spare part for the future.

Got my Tach today from UPS.Won't be able to see if it works until I get my clutch align. tool in to align clutches.Then back go on the carbs,air box and pipes.Then cross my finger I will get a rpm reading.

I don't know,but it is never ending working to get sleds up to parr.But at least I will do it properly and feel assured.

bluemonster1

LIFE MEMBER ONLY ONCE!!!

Had to order 1 mounting bracket for the a-arm also....one was cracked and piece broken off.Boy someone was really rough on this sled and didn't care a damn as far as I can see.Went thru the whole skid and nothing else is broken or missing.Got the transfer rod lower bracketrs off and drilled and tapped for a grease fitting on both of them.Cut some metal coffee can strips and shimmed the bushings so that the metal bushing is tight.Same thing for the front shock in suspension.Took off plastic bushings and shimmed them back in with strips cut from coffee can.The solid bushings now fit inside snug on both ends.I ordered 2 mounting brackets for the mounting arm and will drill and tap them also for a grease fitting just as BethViper suggests.

I had so much play in the w-arm(had no upper bushings in the top rail),combined with loose shock bushings and mounting bracket bushings were all basically destoyed.A-arm with 3 cracks also didn't help.Once I put all new parts and bushings back in,this should really make a difference in the skid for being on plane and straight.Track should also ride better and true.I am learning new things every day.

I had so much play in the w-arm(had no upper bushings in the top rail),combined with loose shock bushings and mounting bracket bushings were all basically destoyed.A-arm with 3 cracks also didn't help.Once I put all new parts and bushings back in,this should really make a difference in the skid for being on plane and straight.Track should also ride better and true.I am learning new things every day.

Exciterfan

Member

Cold!! You're not kidding. This is stupid. If you ride in this weather something WILL break.

Had to fix the plug on my truck's block heater because it decided to stop working last week end. Had to boost the truck Sunday morning. It amazes me that they use such crappy wire on block heaters.

.....Then found out the "Mr. Lube" boy didn't tighten my oil filter properly because I had a nice black pool of oil under the truck once I got it started. Fortunately I caught it in time and avoided a major failure (and the untimely death of the Mr. Lube boy). "doing right before your eyes"...NOT!!!!

Blue... to do things right, you just have to do them yourself!!

Had to fix the plug on my truck's block heater because it decided to stop working last week end. Had to boost the truck Sunday morning. It amazes me that they use such crappy wire on block heaters.

.....Then found out the "Mr. Lube" boy didn't tighten my oil filter properly because I had a nice black pool of oil under the truck once I got it started. Fortunately I caught it in time and avoided a major failure (and the untimely death of the Mr. Lube boy). "doing right before your eyes"...NOT!!!!

Blue... to do things right, you just have to do them yourself!!

bluemonster1

LIFE MEMBER ONLY ONCE!!!

Exciterfan

Member

I don't quite understand where the "coffee can" strips are used. Are you shimming out worn shock bushings??? Must be a better way????

bluemonster1

LIFE MEMBER ONLY ONCE!!!

This idea is from Bethviper.Did this on my SXR front end bushings,everything is tight and snug now.Works great on all plastic bushings.You got to slice a 1/16" out of the bushing so that when the metal strips are inserted,it will close up the bushing.

bluemonster1

LIFE MEMBER ONLY ONCE!!!

Got this idea from Bethviper. Can be done on all plastic bushings to tighten them up.Take a slice of about 1/16" out of the side of the bushing where the split is.The metal shimm strips will close the bushing more and make it snug again.Done it on the front end of the SXR.Do it on transfer rod bushings,shock bushings,trailing arm bushings,radius rod bushings,etc.

daman

New member

post a pic of it monster when you get one ready to put in..bluemonster1 said:Got this idea from Bethviper. Can be done on all plastic bushings to tighten them up.Take a slice of about 1/16" out of the side of the bushing where the split is.The metal shimm strips will close the bushing more and make it snug again.Done it on the front end of the SXR.Do it on transfer rod bushings,shock bushings,trailing arm bushings,radius rod bushings,etc.

w-arm srx

i broke the arms on my srx,viper&rx1. if you pulled the front limiter straps tighter to get more ski presure you need to make sure you readjust the front shock spring tension or it will be to stiff on rebound and the straps will snap the webbing in the arm. (get the straps where you want them thn loosen or tighten the front shock spring till you can turn it by hand) i would also weld the new arm where ever the factory did not. ihad no more problems after doing these two things.

i broke the arms on my srx,viper&rx1. if you pulled the front limiter straps tighter to get more ski presure you need to make sure you readjust the front shock spring tension or it will be to stiff on rebound and the straps will snap the webbing in the arm. (get the straps where you want them thn loosen or tighten the front shock spring till you can turn it by hand) i would also weld the new arm where ever the factory did not. ihad no more problems after doing these two things.