jesseSRX

New member

Does anyone have any additional information about an easy way to adjust the power valves for a 2001 SRX 700?

I remember a post about someone using an allen wrench as a spacer?

I have 5000 mi on this sled and would like to know what kind of important adjusments I should be making. Nothing on this sled has been touched (other than an occasional greasing and power valve cleaning)

Any help is appreciated.

I remember a post about someone using an allen wrench as a spacer?

I have 5000 mi on this sled and would like to know what kind of important adjusments I should be making. Nothing on this sled has been touched (other than an occasional greasing and power valve cleaning)

Any help is appreciated.

daman

New member

try a search...tons of info on this....

2.5mm

2.5mm

marty f

New member

cannot find the valve post

i am looking for the same post and cannot find it under the search engine

i am looking for the same post and cannot find it under the search engine

jesseSRX

New member

Is there any other important 5000 mi maintenance that I should do?

I take the exhaust off and adjust them valves flush with the ports so i know there right on.I would recommend new pistons and rings if you have 5000 miles it's cheaper to do it now then to have to replace your cylinders down the road.

daman

New member

I also would do pistons and rings(use OEM),and go through

and check oil,choke,throttle free play settings,etc..

and check oil,choke,throttle free play settings,etc..

jesseSRX

New member

Thanks guys. I will check it out tonight.

daman

New member

Post back if ya have any more Q's...

jesseSRX

New member

Thanks Daman,

This site is awesome!

Any chance I can call you if I hit a snag?

This site is awesome!

Any chance I can call you if I hit a snag?

daman

New member

sure any time,,PM me for my number....jesseSRX said:Thanks Daman,

Any chance I can call you if I hit a snag?

RIVERRUNNER

Active member

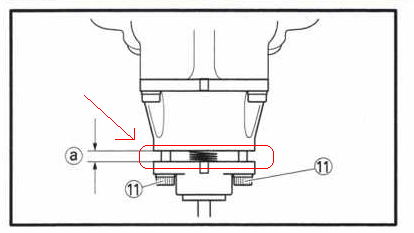

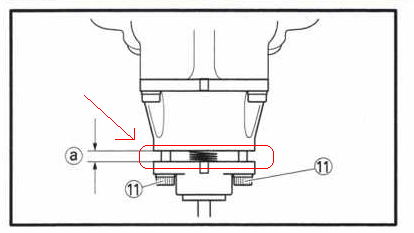

If I was you I would use both methods of setting the power valves!!! I tried the allen wrench method and I messed up and I ended up pulling one of my valves through. It was not a very fun experience. So, if I was you, and when I do it again I am going to use both Yamaha's method which is spacing the out housing from the inner housing. Then I would pull the exhaust headers to make sure that the spacing is right. That is my opinion just my opinion. I would also look up how to make the servo motor wiring harness. It will help you know where you should have the motor with ease.

daman

New member

When i did my PV's i used Yamaha's method with two 2.5mm allen wrenches, then i pulled the pipes and headers and set the servo and checked for flush with my fingers and i was surprised they were spot on!!! perfect...so from now on i'm doing it yamaha's way,allot quicker and IMO set's them perfect...

The only way that improper adjustment causes the cables to pull through is if they are adjusted so tight that the valve hits the stop before the servo is at full open. Your valves may have had ridges in them that caught on the valve recess.

The most accurate way to adjust is to feel through the exhaust ports, however it is important to know what to make the valve flush with. Remember that the valve affects exhaust port height relative to the piston, not exhaust passage size. I always like to check for freeplay once I am done adjusting. I feel that this freeplay is important to allow for differences across all heat ranges.

The most accurate way to adjust is to feel through the exhaust ports, however it is important to know what to make the valve flush with. Remember that the valve affects exhaust port height relative to the piston, not exhaust passage size. I always like to check for freeplay once I am done adjusting. I feel that this freeplay is important to allow for differences across all heat ranges.

daman

New member

This has all been discussed and argued before,he could do a search and

spend hours reading and decide for himself, but IMO yamaha states there procedure in there manual to do this a certain way and i think it's the best,

they should know they designed this motor. and if done correctly it

WILL be right...$.02

spend hours reading and decide for himself, but IMO yamaha states there procedure in there manual to do this a certain way and i think it's the best,

they should know they designed this motor. and if done correctly it

WILL be right...$.02

bluemonster1

LIFE MEMBER ONLY ONCE!!!

I`ll give you $.03 for that daman.I agree,the 2.5 is accurate,but take your time and don`t rush it.I did the exhaust port feel,put it all back and ran it.Didn`t seem real snappy.Then went back and did the 2.5 method,back into the ditch and pinned it.It was toatally awesome then,snapped like unreal.So I will continue the Yamaha method myself,use 2 allens wrenchs 2.5mm as your spacer.