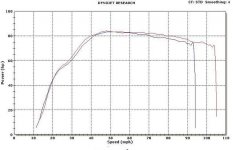

Here is a little bit of real world information regarding a speed sheave VS a stock yamaha sheave. You can see how the speed sheave trnsmits LESS power to the track then stock does, this is due again to the bending of the belt up in overdrive, resulting in a tight bending small radius in the secondary. The test were conducted on a stock Apex, 23/38 gearing was used in both test and the rpm was within 50rpm on both test, the only componet changed was the sheave itself.

This topic is always debated on here and some of the people think its only a "theory" where as you can see that Olav Aaen relays more then just theory , he proivides you with accurate information that is applicable to real world results helping you go faster and faster.

This topic is always debated on here and some of the people think its only a "theory" where as you can see that Olav Aaen relays more then just theory , he proivides you with accurate information that is applicable to real world results helping you go faster and faster.

Attachments

Was this Hauck's speed sheave?

Great info!

I have never found speed sheaves to work.

Cut overdrive works, it has for me anyway.

The above comparison is designed to fail. Not very scientific. They dyno run the same clutching with a different clutch face. To take advantage of any change to the clutch faces, you would need to adjust the weights, rollers or neutral and or gear down to compensate.

Also, this is one of those one face OD kits, not a true OD. It only changes the angle of one sheave so your not only bending the belt around, your twisting it on the clutch so that it wont be running paralell to the crank. This style of OD will never be as efficient as real OD which runs the belt paralell to the crank.

If they had done the discount OD in this test they would have seen absolutely no loss in power what so ever as the clutch sheave is not changed. This is where you cut the inside lower section of both of your sheaves and the split collars while they are installed. .035 off each is what will keep the cut line below engagement.

Now gear that discount OD down a tooth top or bottom, adjust the clutching so it runs the same rpms and then lets see what the hp numbers say at similar speeds?

There is another OD that recuts the lower angle and the flat, and another that recuts the sheaves about 1/2 a degree evenly from the top down and then the flat, another that is just different sheaves, forgot the degrees but they are flatter and come on some years of vk sleds. All three of these require neutral to be reset(grind split collars).

If your going to try for top speed or radar runs, OD I don't see as any advantage. Physics is still physics and 1-1 is the most efficient you can bend a belt. But for building a trail sled, Od can give you a little more when the conditions permit and allow for a little lower gearing, if you like that sort of thing.

I found the best situations that OD works for is the show up lake racing. I could run really low gears and get them on the bottom, and OD helped me stay ahead on the top even though I had those low gears.

My point is, Olav really didn't prove anything other than if you change one thing on your clutch, you might lose some power. Not to mention, this whole test was about OD and they tested the track speed to around 100mph. Since we don't know which style of sheave this is, we are not sure the transition on an OD sheave would even be used at that point.

Bored on saturday moring.

Cut overdrive works, it has for me anyway.

The above comparison is designed to fail. Not very scientific. They dyno run the same clutching with a different clutch face. To take advantage of any change to the clutch faces, you would need to adjust the weights, rollers or neutral and or gear down to compensate.

Also, this is one of those one face OD kits, not a true OD. It only changes the angle of one sheave so your not only bending the belt around, your twisting it on the clutch so that it wont be running paralell to the crank. This style of OD will never be as efficient as real OD which runs the belt paralell to the crank.

If they had done the discount OD in this test they would have seen absolutely no loss in power what so ever as the clutch sheave is not changed. This is where you cut the inside lower section of both of your sheaves and the split collars while they are installed. .035 off each is what will keep the cut line below engagement.

Now gear that discount OD down a tooth top or bottom, adjust the clutching so it runs the same rpms and then lets see what the hp numbers say at similar speeds?

There is another OD that recuts the lower angle and the flat, and another that recuts the sheaves about 1/2 a degree evenly from the top down and then the flat, another that is just different sheaves, forgot the degrees but they are flatter and come on some years of vk sleds. All three of these require neutral to be reset(grind split collars).

If your going to try for top speed or radar runs, OD I don't see as any advantage. Physics is still physics and 1-1 is the most efficient you can bend a belt. But for building a trail sled, Od can give you a little more when the conditions permit and allow for a little lower gearing, if you like that sort of thing.

I found the best situations that OD works for is the show up lake racing. I could run really low gears and get them on the bottom, and OD helped me stay ahead on the top even though I had those low gears.

My point is, Olav really didn't prove anything other than if you change one thing on your clutch, you might lose some power. Not to mention, this whole test was about OD and they tested the track speed to around 100mph. Since we don't know which style of sheave this is, we are not sure the transition on an OD sheave would even be used at that point.

Bored on saturday moring.

Last edited:

YAMMIEGOD3:16

Active member

ADDED A HAUCK OVERDRIVE SHEAVE FOR GRASS DRAG,IN ON MY 1995 VMAX 4 800 THIS SLED FEELS WAY STRONGER MID AND TOP, BUT I CAN,T CONFIRM UNTIL RUN ON TIMERS. LET ME PUT IT THIS WAY, ITS NOT SLOWER THAN STOCK SHEAVE. feels all of the same if not better. 3:16 (yammie tony)

jabber800

New member

Tony if you geared down to take advantage of the extra overdrive, the 800 would feel stronger down low and in the midrange!! Where the problems start is when the clutch face changes angle and is no longer parallel to the belt side angles. Anyone that would like to try to prove this is welcome to come over for an afternoon and prove it on my track dyno.. If you can make more HP with the overdrive sheave on the big end than I can make on the same sled with the stock sheave the dyno fees will be free! You pay if you lose!!

YAMMIEGOD3:16

Active member

DAN, YES THATS MY NEXT STEP TO GEAR DOWN. KEEP IN MIND HERE THIS MACHINE ONLY GOING 500 F.T. !! 3:16 (yammie tony)

look at the date of the first post, someone brought it back from 3 years ago....

1.) it clearly shows they dont work, you dont change componets to get a part to work so you can show better numbers then the marketed the part with no mention you geared down,changed weights,changed parts...lmao, thats ridiculous. How about adding more power to the motor as well and then track dyno it, kind of defeating the purpose, where does it end with changing parts to add the power from the first part..

2.) this track dyno test was not done by Aaen

3.) yes, the test also relays the speed sheave with 2 differnt sheave angles isnt as good as its "sold as", nothing new there, however it also still puts the belt into overdrive,so you have a combo of both negative results there.

1.) it clearly shows they dont work, you dont change componets to get a part to work so you can show better numbers then the marketed the part with no mention you geared down,changed weights,changed parts...lmao, thats ridiculous. How about adding more power to the motor as well and then track dyno it, kind of defeating the purpose, where does it end with changing parts to add the power from the first part..

2.) this track dyno test was not done by Aaen

3.) yes, the test also relays the speed sheave with 2 differnt sheave angles isnt as good as its "sold as", nothing new there, however it also still puts the belt into overdrive,so you have a combo of both negative results there.