Fro

New member

Is the reason to mark the servo so if it moves at all during the cable adjustment you can rotate it back to that spot? So the 2.5mm is maintained on all 3 valves at the fully open position. It seems like when you barely go smaller than 2.5mm it will move.

I'm dead nuts on all 3, but wanted to make sure before I start it tomorrow. Is there any reason to mark the closed position? If so, do you do it while it is at normal idle? I would assume it rotates clockwise to close them.

Is there a specified distance the servo should travel between open & closed? Alot of questions, just trying to fully understand. Thanks.

I'm dead nuts on all 3, but wanted to make sure before I start it tomorrow. Is there any reason to mark the closed position? If so, do you do it while it is at normal idle? I would assume it rotates clockwise to close them.

Is there a specified distance the servo should travel between open & closed? Alot of questions, just trying to fully understand. Thanks.

Viper-Rules!

New member

Power valves!

Actually I'm just going through the whole adjustment process now. What are you measuring to get the 2.5mm gap? Hard to tell from the pic. I know you take out the two screws and move the adjustors in or out.

Actually the servo motor moves counter clockwise to close them and clock wise to open them. If you set it the other way your cables will kink and criss cross in a hurry.

Actually I'm just going through the whole adjustment process now. What are you measuring to get the 2.5mm gap? Hard to tell from the pic. I know you take out the two screws and move the adjustors in or out.

Actually the servo motor moves counter clockwise to close them and clock wise to open them. If you set it the other way your cables will kink and criss cross in a hurry.

daman

New member

Yes you have to be very carefull when tighen the cables as it will pull the

servo out of adjustment, yes thats the reason for making the mark

servo out of adjustment, yes thats the reason for making the mark

daman

New member

1-set servo,start engine and lower idle to 900 rpm's,(not necessary on viper ER's,just turn the key on),then make your marks on the servo(helps later if it moves on ya)turn off key(viper ER's).then shut down engine.

2- loosen the cables all the way up @ the servo cable adjusters

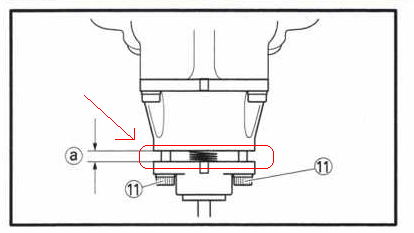

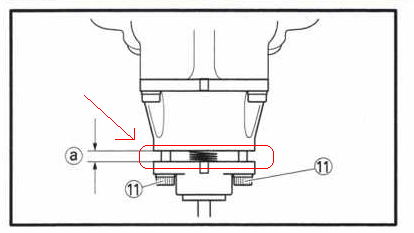

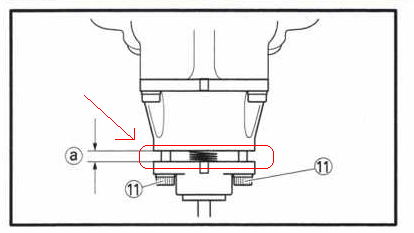

3-loosen the two allen bolts #11 @ the pv houseing and pull it back

4-insert the allen wrench's(2.5mm,)top picture, go back up to the servo and GENTLY

tight'en the cable adjusters so it pulls the two P/V housings together, so it just tuches the wrench, then pull out wrench and tight'en the two bolts and the cable adjuster lock nut.

5- re-peat steps 2-4 on the other two cables

2- loosen the cables all the way up @ the servo cable adjusters

3-loosen the two allen bolts #11 @ the pv houseing and pull it back

4-insert the allen wrench's(2.5mm,)top picture, go back up to the servo and GENTLY

tight'en the cable adjusters so it pulls the two P/V housings together, so it just tuches the wrench, then pull out wrench and tight'en the two bolts and the cable adjuster lock nut.

5- re-peat steps 2-4 on the other two cables

Last edited:

RIVERRUNNER

Active member

Nice picture Daman........I can spot my heads anywhere!!!!!!!!!!LOL

daman

New member

yup your a famous guy.RIVERRUNNER said:Nice picture Daman........I can spot my heads anywhere!!!!!!!!!!LOL

Viper-Rules!

New member

Got it!

Do you adjust with the valves fully open or closed? I'm assuiming closed? Thanks

Steve

Do you adjust with the valves fully open or closed? I'm assuiming closed? Thanks

Steve

daman

New member

when you set the servo the valves will be open..Viper-Rules! said:Do you adjust with the valves fully open or closed? I'm assuiming closed? Thanks

Steve

akrievins

New member

Daman, that must be one of the best pictures I've seen for adjusting powervalves. After seeing that, I may just actually attempt cleaning my PV's by myself. I might bring it to a shop first so I can see how everything else is done, but after that I'd give it a go. I just don't want to mess anything up with my Viper.

You really do post some great info.

Thanks!

You really do post some great info.

Thanks!

daman

New member

lol, thanks akrievins.... i stole the engine pic from RIVERRUNNERakrievins said:Daman, that must be one of the best pictures I've seen for adjusting powervalves. After seeing that, I may just actually attempt cleaning my PV's by myself. I might bring it to a shop first so I can see how everything else is done, but after that I'd give it a go. I just don't want to mess anything up with my Viper.

You really do post some great info.

Thanks!

going to take my own but hey if i can save time right. lol

anyway it's really strait forward procedure with the info on this site

i'd like to see ya do it on your own instead of pay $ at a dealer, but

do what's comfortable to you.

Excellent pictures and step by step guide Daman!!! Very nice!!

I adjusted mine the other day on my 98' SRX and found it to be a rather easy prodedure. It also made a nice improvement in power too, unfortunately a bit too much of an improvement as now I'm over revving by 300rpm so I now have to do a bit more clutch work to get it back down to 8300rpm!!

I adjusted mine the other day on my 98' SRX and found it to be a rather easy prodedure. It also made a nice improvement in power too, unfortunately a bit too much of an improvement as now I'm over revving by 300rpm so I now have to do a bit more clutch work to get it back down to 8300rpm!!

daman

New member

thanks.

i believe you need more weight in the tip(4.5g), should help bring it down, but one of the clutch boys will tell ya for sure..

what are you revving too?

i believe you need more weight in the tip(4.5g), should help bring it down, but one of the clutch boys will tell ya for sure..

what are you revving too?

I didn't have chance to hold it for too long of a stretch, only till I hit about 130kms [80mph] but the tach was sitting at 8500rpm and then 8600 just as I let off. When I bought it the previous owner had told me he went to 8 tooth drivers b/c of clearence issues with the 1.25 track and he also said it had lower gears in the chain case but I haven't taken the cover off to see what's actually in there. I'm betting there's already pretty heavy rivits in the weights [stock clutches and weights]. I'm told 8300rpm's is where I want to be with a 98' [which was where it was till I adjusted the PV's] but I'm going to have a look around to see if I can find a dyno sheet and see if 8600 is indeed higher than I want to be. I'm going to pop on a new belt first and see what that does.daman said:thanks.

i believe you need more weight in the tip(4.5g), should help bring it down, but one of the clutch boys will tell ya for sure..

what are you revving too?

daman

New member

Yes you want to be @ 8300 top end on a '98

Rats, I was hoping you weren't going to say that! LOLdaman said:Yes you want to be @ 8300 top end on a '98

Thanks Daman!!

mdbauer62

Member

daman said:1-set servo(lower idle below 900 rpm)

2- loosen the cables all the way up @ the servo adjusters

3-loosen the two allen bolts @ the pv houseing and pull it back

4-insert the allen wrench's(2.5mm), go back up to the servo and GENTLY

tight'en the cable so it just tuches the wrench, then pull out wrench

and tight'en the two bolts,

5- re-peat on the other two cables

Daman, with a Viper ER, am I correct that I do not need the engine running, but just turn the key on, and then follow your procedure? Do I need to remove the servo cover at all?

daman

New member

Yes you are correct on the ER,because it has a battery already the servo has power avalible.mdbauer62 said:Daman, with a Viper ER, am I correct that I do not need the engine running, but just turn the key on, and then follow your procedure? Do I need to remove the servo cover at all?

and yes i would pull off the cove to make sure it cycled.