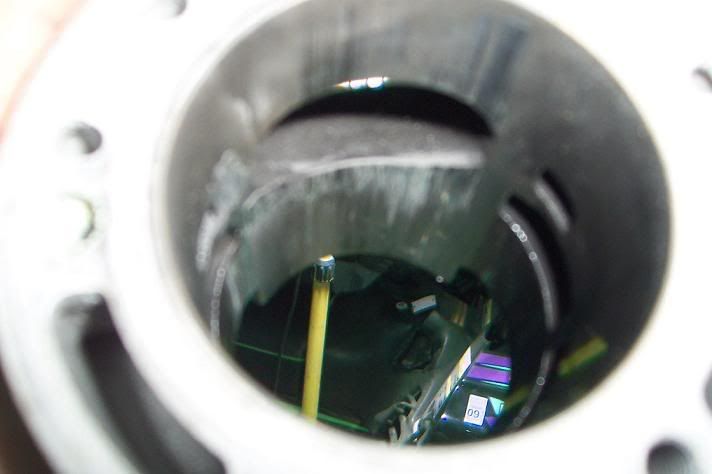

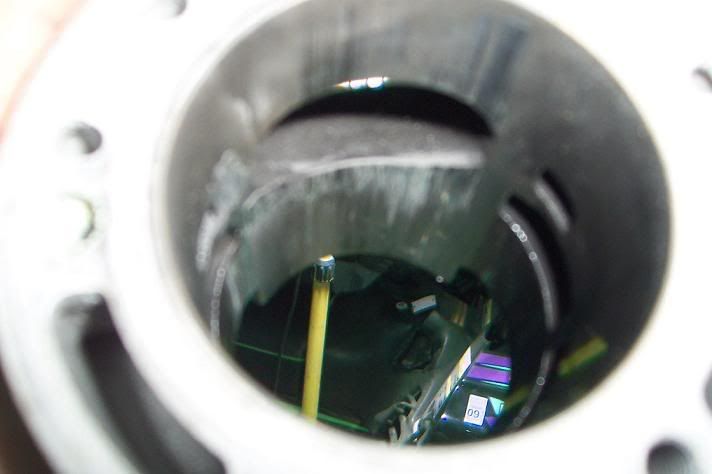

Tonight I was cleaning the cases for the viper and found something interesting.

On the case where the mag side cylinder attaches (the one that burned down) I found a raised area from where it appears someone hit the rod against the case(See pics)

Keep in mind this engine has been rebuilt before, before I owned it, and I don't think it was the greatest quality workmanship. I set the cylinder on there to check it out, and sure enough it doesn't sit flat and can be rocked a little. You can see a gap between the cylinder and case.

SO....I'm thinking maybe that the gasket didn't seal very well because of this, it let air leak in, and the result was the burndown. What do you guys think??

On the case where the mag side cylinder attaches (the one that burned down) I found a raised area from where it appears someone hit the rod against the case(See pics)

Keep in mind this engine has been rebuilt before, before I owned it, and I don't think it was the greatest quality workmanship. I set the cylinder on there to check it out, and sure enough it doesn't sit flat and can be rocked a little. You can see a gap between the cylinder and case.

SO....I'm thinking maybe that the gasket didn't seal very well because of this, it let air leak in, and the result was the burndown. What do you guys think??

Attachments

yep it could be possible ...

change_up

New member

I would put money on it and say that was most definetly the cause. I beleive the gasket sits tight around both edges of that area, so the gasket would have been affected by that spot. I would say you've found the problem.

mm700sleder

New member

i would have to agree with change up, but i wouldn't rule this as the sole cause yet. you might what to inspect more to see if it could possibly be anything else. i hate for you to rebuild and find out it was something else. well if it is that, what an easy fix

I suppose I'll just use emery cloth or something to remove the high spot. This is really the only obvious thing that showed up, the crank seals looked fine, the carb was spotless inside, I'll be putting everything back together with new crank seals and gaskets then finally I think I'm going to have a leakdown test done just to make sure everything is ok.

valin

Active member

When you pulled it apart, did you find any oil/fuel leakage from that area on the outside of the cylinder/cases? It looks like you might have cleaned things up before you took the pictures. If you did not clean things up, it doesn't appear as if it were leaking in that area. Do you have pictures of what the piston and cylinder looks like? That would certainly tell the story alot better.

opsled

Active member

A little tip for you to test cases and seals for leaks before complete dissassembly or during a rebuild. One I use all the time. After you get the cylinders off fill the crankcase with clean fuel one cylinder at a time. If an end seal, center seal or mating halves of the crankcase have an issue fuel will leak out. Filling them one at a time allows you to check for center seal leakage to the next cylinder. If there are no leaks move on to the next one and repeat. You can also do this on an engine during the assembly process to double check your work before installing the cylinders. If everything looks good just dump the fuel, blow it out and reoil everything before you move on.

Good Luck, opsled

Good Luck, opsled

valin - I did clean it up already. There was some black oily/dirty stuff on top of the intake that I cleaned off with a paper towel, I guess I wasn't paying that much attention. On the exhaust side of the case there's a definite line of oily gunk down the side, though that's probably from the powervalve, I don't know for sure because CB Performance cleaned up the cylinder. Ill attach pics of the piston and cylinder from when I took it apart.

opsled - I don't think I have any center seals, at least on the viper, just the bearings and the half-moon circlip things. Are they supposed to be able to hold a seal between cylinders?

Also, after you dump the gas and blow it out, how do you reoil everything in there with the cases together?

I'll try the gas thing for the cases but I still think I'm going to have a leak down test done to check everything when it's done.

Piston (exhaust side) - also you can see a little bit of the base gasket and the residue on the intake (ignore the coolant, that was from disassembly)

Cylinder (bad pic sorry)-

opsled - I don't think I have any center seals, at least on the viper, just the bearings and the half-moon circlip things. Are they supposed to be able to hold a seal between cylinders?

Also, after you dump the gas and blow it out, how do you reoil everything in there with the cases together?

I'll try the gas thing for the cases but I still think I'm going to have a leak down test done to check everything when it's done.

Piston (exhaust side) - also you can see a little bit of the base gasket and the residue on the intake (ignore the coolant, that was from disassembly)

Cylinder (bad pic sorry)-

opsled

Active member

They all have center seals. Each cylinder on a two stroke needs to be sealed not only from the outside but also from any neighboring cylinders. Center seals are of a different type than end seals and arn't prone to as many problems but they can go bad. There are holes in the upper crankcase half that feed fuel/oil down to the bearings. There is usually at least one on either side of the rod a sometimes more depending on the engine. Just squirt some 2 srtoke oil down them while rotating the crank. When you see some oil starting to puddle in the bottom of the crankcase, the bearings have been oiled.

A leak down test is always a good thing to do but you could still pass a leak down test with a bad center seal depending on how the test was done. If each cylinder was tested independantly from the others while the other cylinder's ports are open you should find any problems if they igsist. If you test them all together or one at a time with all the cylinder's ports sealed a bad center seal won't show up.

The fuel in the crankcase trick works well when you are trying to diagnose a potential problem during dissassembly and to check your work (or your crank guys work) during reassembly of the bottom end. If the bottom end passes the fuel test before you install the top end you will at least know that part of the job it is done right.

Good Luck, opsled

A leak down test is always a good thing to do but you could still pass a leak down test with a bad center seal depending on how the test was done. If each cylinder was tested independantly from the others while the other cylinder's ports are open you should find any problems if they igsist. If you test them all together or one at a time with all the cylinder's ports sealed a bad center seal won't show up.

The fuel in the crankcase trick works well when you are trying to diagnose a potential problem during dissassembly and to check your work (or your crank guys work) during reassembly of the bottom end. If the bottom end passes the fuel test before you install the top end you will at least know that part of the job it is done right.

Good Luck, opsled

valin

Active member

Man, that thing must have been working away for a while. I've never seen a piston detonated so far that it results in a hole in the skirt. Good job.

Do you have a picture of the cylinder head?

Do you have a picture of the cylinder head?

valin said:Man, that thing must have been working away for a while. I've never seen a piston detonated so far that it results in a hole in the skirt. Good job.

Do you have a picture of the cylinder head?

Thanks

I'll get one of the head, but I don't know if there's much to see. It's just gray, like the plug.

If this helps any, here's the story on this sled, kinda long...  don't make fun of my ignorance haha, I learned SO MUCH since I found this site.

don't make fun of my ignorance haha, I learned SO MUCH since I found this site.

I had never owned a 2 stroke motor before, I didn't know much about them, though I've been all through 4 stroke motors before and I own a raptor 660. I bought the sled last february from the local dealer, it had 900 miles on it. They had been asking $4000 for it but they had a big inventory reduction sale on all sleds because there was no snow, and I got it for $2500 which I thought was a great deal. Some guy had traded it in the year before so the dealer had it for a year. When I bought it, they said that they ran it thru the shop and made sure everything was ok. The sled seemed to run good and I put 500 miles on it. For summer storage I put sta-bil in the fuel and that was it, I didn't know any better or what fogging was at the time. So this year I started it and it idled crappy, I cleaned the entire carbs, jets, passages, etc with the help of this site that I just found and it ran great it had a little bit of an idle hang. Probably in the first 20 miles I rode it, it shut down on me, and it seemed to be locked up. Me and the guy I was with (he's not very mechanically inclined, lol, and this was my first sled so I'm clueless) thought the primary stuck or something, because we turned it a little and it seemed perfectly normal. Started right off and had good power. When I got home I checked the plugs, the mag side looked kind of dark gray compared to the others. I had never actually seen a lean plug before and thought it would be white or a lighter color, so I thought nothing of it. 50 miles later, the same thing happens again, cept this time I have to limp it luckily only 1/2 mile home on 2 cylinders, take it apart and here I am with a hole in the skirt of the mag piston. Then as I take it apart, I can see very obviously that sometime in its short 900 mile lifetime it had been rebuilt, and it was kind of a shoddy job. Whoever did it used some cheap aftermarket pistons, used some wrong bolts, and was responsible for the high spot on the case. Also, I found that one of the oil lines going to the fuel pump had a pin hole in it. So here I am now rebuilding it with new seals and gaskets, and oem pistons and rings for the top end. Is it possible that it was leaking throughout 500 miles of riding last year, somehow got worse from sitting over the summer without being fogged, and finally went this year?

don't make fun of my ignorance haha, I learned SO MUCH since I found this site.

don't make fun of my ignorance haha, I learned SO MUCH since I found this site.I had never owned a 2 stroke motor before, I didn't know much about them, though I've been all through 4 stroke motors before and I own a raptor 660. I bought the sled last february from the local dealer, it had 900 miles on it. They had been asking $4000 for it but they had a big inventory reduction sale on all sleds because there was no snow, and I got it for $2500 which I thought was a great deal. Some guy had traded it in the year before so the dealer had it for a year. When I bought it, they said that they ran it thru the shop and made sure everything was ok. The sled seemed to run good and I put 500 miles on it. For summer storage I put sta-bil in the fuel and that was it, I didn't know any better or what fogging was at the time. So this year I started it and it idled crappy, I cleaned the entire carbs, jets, passages, etc with the help of this site that I just found and it ran great it had a little bit of an idle hang. Probably in the first 20 miles I rode it, it shut down on me, and it seemed to be locked up. Me and the guy I was with (he's not very mechanically inclined, lol, and this was my first sled so I'm clueless) thought the primary stuck or something, because we turned it a little and it seemed perfectly normal. Started right off and had good power. When I got home I checked the plugs, the mag side looked kind of dark gray compared to the others. I had never actually seen a lean plug before and thought it would be white or a lighter color, so I thought nothing of it. 50 miles later, the same thing happens again, cept this time I have to limp it luckily only 1/2 mile home on 2 cylinders, take it apart and here I am with a hole in the skirt of the mag piston. Then as I take it apart, I can see very obviously that sometime in its short 900 mile lifetime it had been rebuilt, and it was kind of a shoddy job. Whoever did it used some cheap aftermarket pistons, used some wrong bolts, and was responsible for the high spot on the case. Also, I found that one of the oil lines going to the fuel pump had a pin hole in it. So here I am now rebuilding it with new seals and gaskets, and oem pistons and rings for the top end. Is it possible that it was leaking throughout 500 miles of riding last year, somehow got worse from sitting over the summer without being fogged, and finally went this year?

davessrx

New member

Hey anything is possible, Check the crank bearing out too if it was loosing oil!!!! Sometimes you think you get a great deal and you don't, lesson learned. I have been guilty of this too. Good Luck with the rebuild.

valin

Active member

If you still have the piston, take a picture of the bottom of it (inside). I am curious to see the colouring of it. I am just curious to see if oil was part of the culprit. Also, was the top of the piston detonated severely in the middle? Was it starting to wear through the piston?

I've attached pics of the piston domes, insides, and the head. The dome of the burned piston is still intact, it wasn't wearing through that I can see.

The crank bearings seem fine, I don't think it was losing enough oil to make a difference. It was a pin hole in the hose that was only visible when you bend it over. Thanks for the help btw, I appreciate it.

The crank bearings seem fine, I don't think it was losing enough oil to make a difference. It was a pin hole in the hose that was only visible when you bend it over. Thanks for the help btw, I appreciate it.

Attachments

valin

Active member

Is the top of the piston that burnt starting to wear a dome in it? It's hard to tell in the pictures.

valin

Active member

and was the cylinder only scored on the exhaust side?

valin said:Is the top of the piston that burnt starting to wear a dome in it? It's hard to tell in the pictures.

No, it's the same as the others. The only wear is what you can see on the side. I accidentally broke the skirt taking it off, otherwise it was all intact.

valin said:and was the cylinder only scored on the exhaust side?

Yes, it's by far the worst on the exhaust side. There are some marks on the intake side but they weren't too bad and the cylinder looked ok on that side.