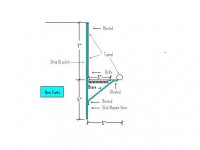

What is the best material for thin (1/8") drop brackets? I know the strength of the different (actually can look them up online), but don't know which material is the best for forming. The drop brackets I need extend 5 inches below the tunnel, so pretty sure I need a brace that attaches to the outside of the running board (over the heat exchanger).

Materials I am looking at include . . .

Any fabricators out there?

Materials I am looking at include . . .

- 316 Stainless (annealed) - is it strong enough?

- 7075-T6 Aluminum - can it be formed without becoming weak?

- 17-4 PH Stainless (annealed) - way too expensive?

- Some form of steel - which one and how to resist rust?

Any fabricators out there?

Ding one of the stainless that I know is hard as HeLL, think its 406??

7075 should work for you if you add some sort of stiffner bead or flanges to aleviate fold over and you could support it with a gusset that you explain to add strength. How thick of 7075 are you looking to use? 1/8" or thicker?

You could also use steel in the way that i am thinking also it would need to be powder coated well.

7075 should work for you if you add some sort of stiffner bead or flanges to aleviate fold over and you could support it with a gusset that you explain to add strength. How thick of 7075 are you looking to use? 1/8" or thicker?

You could also use steel in the way that i am thinking also it would need to be powder coated well.

WATCHMAKER

Member

Personally I would use 7075 for the vertical piece and 6061 or 5052 for the brace. 7075 will not bend without cracking and you can't weld it. For the brace I would try 6061 first but sometimes it will crack also but with only a 45 degree bend it should work. If 6061 cracks when you try to bend it then use 5052. All these alloys are light and easy to cut, drill, file and sand.

Last edited:

WATCHMAKER

Member

Another thing you could do is extend the bottom flange of the brace enough so the skid bolt goes through it and the vertical piece together. Make the lower bend of the brace just above the skid bolt hole. That will increase the strength.

Damn it Watchmaker!? you're reading my mind on post #5! :-)

You should be able to bend 6061 45* without it cracking it may get a little grainy though, you may also be able to anneal the area that you wish to bend/break to allow you to get the bend you need. I agree on the 7075, that it does not bend well.

GREAT idea tohough to use 7075 for the straight bracket and 6061 forthe support.

You should be able to bend 6061 45* without it cracking it may get a little grainy though, you may also be able to anneal the area that you wish to bend/break to allow you to get the bend you need. I agree on the 7075, that it does not bend well.

GREAT idea tohough to use 7075 for the straight bracket and 6061 forthe support.

6061 would be more then strong enough for both parts in my opnion, easily found,reasonable price. Theres no real load there unless you land sideways off a jump, then I figure youll have more problems then just a bracket....lol

WATCHMAKER

Member

Some of the strength will depend on how wide the brackets are. (you only show an end view) I agree 6061 should work if you brackets are wide enough. How wide do you plan to make them? A great place to buy small quantities of metals is onlinemetals.com

Thanks for all the input guys! !!!

Yah, the brackets I have now are 6061-T6 that came from onlinemetals.com. The problem is that they are 1/2 inch thick. No room for a 16 inch track.

I can make them 4, 5 inches or even more wide if needed.,,,

I'll post pics of the current ones Friday.

Yah, the brackets I have now are 6061-T6 that came from onlinemetals.com. The problem is that they are 1/2 inch thick. No room for a 16 inch track.

I can make them 4, 5 inches or even more wide if needed.,,,

I'll post pics of the current ones Friday.