Hi guys

I was wondering, since I cant get a hold of a aftermarket head for my viper w dcs. couldnt u take srx heads and water rail, and then manufacture a "holder" for the dcs and weld the "holder" on the water rail, just install the dcs and everything would work like a charm?

I know theres a guy on this forum who made a speedwerx head compatible w dcs by doing the same thing i mentioned above.

the dcs "reads" the frequenzy from a bad detonation if I remember right? so it should work?

tell my ur thoughts about it, or if someone has a mega power, pioneer perf or mountain perf. head for sale with a reasonable price pm me

Thanks

Jonatan

I was wondering, since I cant get a hold of a aftermarket head for my viper w dcs. couldnt u take srx heads and water rail, and then manufacture a "holder" for the dcs and weld the "holder" on the water rail, just install the dcs and everything would work like a charm?

I know theres a guy on this forum who made a speedwerx head compatible w dcs by doing the same thing i mentioned above.

the dcs "reads" the frequenzy from a bad detonation if I remember right? so it should work?

tell my ur thoughts about it, or if someone has a mega power, pioneer perf or mountain perf. head for sale with a reasonable price pm me

Thanks

Jonatan

dirtjumper895

New member

I am thinking i am "that guy" .

As for how it works, i think it works pretty freakin sweet. I have yet to had any problems with detonation, and the sensor definitely does read when it could be detonating.

Two things i would change-

1st, would be to insert a steel insert in the boss that gets welded on, so the senor has steel threads to thread into. (mine with just aluminum threads got loose after a year or so, a helicoil fixed it.)

2nd, would be to possibly try and de-sensatize the sensor slightly using a plastic or rubber sealing washer.

As for how it works, i think it works pretty freakin sweet. I have yet to had any problems with detonation, and the sensor definitely does read when it could be detonating.

Two things i would change-

1st, would be to insert a steel insert in the boss that gets welded on, so the senor has steel threads to thread into. (mine with just aluminum threads got loose after a year or so, a helicoil fixed it.)

2nd, would be to possibly try and de-sensatize the sensor slightly using a plastic or rubber sealing washer.

yeah u are "that guy"

So how would u get that steel "boss" in the aluminium "bung" as called it in ur thread?

So how would u get that steel "boss" in the aluminium "bung" as called it in ur thread?

dirtjumper895

New member

Well when i made my "bung" i simply turned it on a lathe, and drill and tapped the threaded hole.

To do it the way i described, i would turn the bung once again. Lets say we wanted 20mm of threads, and had an overall length of the bung was 22 mm. I would drill a hole in the head's side of the bung big enough for the insert, and then the hole for the sensor.

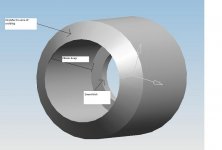

Here is a really crude drawing of how i would do it again.

To do it the way i described, i would turn the bung once again. Lets say we wanted 20mm of threads, and had an overall length of the bung was 22 mm. I would drill a hole in the head's side of the bung big enough for the insert, and then the hole for the sensor.

Here is a really crude drawing of how i would do it again.

Attachments

do I get it right?

first u do a alu bung like the one u drawed, and then make an steel insert that will fit inside the alu bung and then make a threaded hole in the insert which the dcs sensor goes in to?

but then you still have the hard vs soft material problem with the steel insert to alu bung?

first u do a alu bung like the one u drawed, and then make an steel insert that will fit inside the alu bung and then make a threaded hole in the insert which the dcs sensor goes in to?

but then you still have the hard vs soft material problem with the steel insert to alu bung?

mopar1rules

Active member

yay, solidworks drawing!! lol. i LOVE solidworks.

dirtjumper895

New member

Haha that was actually Unigraphics NX5... same thing however

I would look up threaded inserts on the internet and make the inner dimension of the bung a clearance fit with the outer diameter of the insert. This step is just to ensure you will never have problems with stripping the bung. I was saying all sorts of new words once i stripped mine out. So if i was to do it again i would per-say "over engineer" the parts that irritated the hell out of me.

I would look up threaded inserts on the internet and make the inner dimension of the bung a clearance fit with the outer diameter of the insert. This step is just to ensure you will never have problems with stripping the bung. I was saying all sorts of new words once i stripped mine out. So if i was to do it again i would per-say "over engineer" the parts that irritated the hell out of me.