Hello All! First post and first lower engine rebuild on a sled. I picked up this 2003 Viper for cheap knowing it had engine problems. Supposedly it only has 150 miles on it, but apparently it has a wiped lower rod bearing. Got the thing tore apart and have sent the crank off to Jeff at Midwest Crankshafts to get checked out. So we are moving in the right direction.

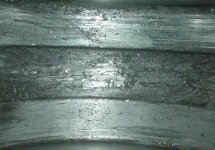

My current question is if I should be worried about the crank casing. There is a crack where it looks like the center rod has broken through the casing when the bearing went. Should I get this welded or what do you guys think? Also, the inside of the center area is pretty banged up.

Also, this sled doesn't have electric start but is there a way I can power up the guage to verify the mileage on this thing?

Thanks for the help!

My current question is if I should be worried about the crank casing. There is a crack where it looks like the center rod has broken through the casing when the bearing went. Should I get this welded or what do you guys think? Also, the inside of the center area is pretty banged up.

Also, this sled doesn't have electric start but is there a way I can power up the guage to verify the mileage on this thing?

Thanks for the help!

Attachments

3 options:

1.) tig weld the crack from bottomside and then smooth off inside with dremel tool

2.) put case bottom on bridgeport table, take a small saw cutter and go around the inside of the webbing cutting a small slice open just into the webs, not thru them, like .030-.040" deep around perimeter. Then use Devcon or like epoxy and pour into the void. The slot you cut will keep the epoxy from coming out(like a lip seal)

3.) replace the case with a known good one.

1.) tig weld the crack from bottomside and then smooth off inside with dremel tool

2.) put case bottom on bridgeport table, take a small saw cutter and go around the inside of the webbing cutting a small slice open just into the webs, not thru them, like .030-.040" deep around perimeter. Then use Devcon or like epoxy and pour into the void. The slot you cut will keep the epoxy from coming out(like a lip seal)

3.) replace the case with a known good one.

davidgboy

New member

i would go with option 1. does not look that serious in structual terms. check case mating surface on a reliably flat surface. piece of glass put on a countertop might work good. look for any gaps. make sure surface of case is perfectly clean. very tight tolerances i would think. make sure person doing welding is competent. dont heat up case much. check for flatness again after welding. u got lucky i think. thanx mrviper700 for your knowledge and time.

pitz0022

New member

I had one that looked worse than that and I had it welded for less than $100. However for a little over $100 you might be able to find a new case.

As for verifiying the miles, if you know of someone in your area with a viper, you could hook it up to their sled and start it.

As for verifiying the miles, if you know of someone in your area with a viper, you could hook it up to their sled and start it.

I would just get a new/used case and not worry about the repair in the future. If you do fix it, it's going to be in the back of your mind while riding all the time.

viperking

Active member

I have a set of used cases for $150 if you're interested let me know Thanks

viperking said:I have a set of used cases for $150 if you're interested let me know Thanks

I would go this route as mentioned above. For the price of welding it you might as well get a clean set of cases. Also, you can not mix lower and upper halfs. They are a matched set.

davidgboy

New member

if u can get a set of cases for $150, then that would be the best bet. thats a real good price it seems. always keep the original for emergency back up.(once repaired)