biglsells

VIP Member

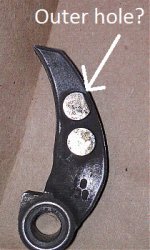

ok I have been working on my primary clutch and decided it needed some new parts. A couple of the weights look to be worn pretty bad and I heard that can cause the clutch to bind up so I have three brand new weights (remember first time doing this) and duh, they all have holes in them. Is there a way to get the inserts out of my old weights and push them into these new ones? Here are a couple pics (this weight is the least worn, would you say its ok?) see how the inserts are crushed or flared at one side? What do I do now?

Attachments

no reusing those rivets, you have to drill them out to remove them.

those apear to be heavily loaded, or installed wrong. cant tell by the pics but something just doesnt look right.

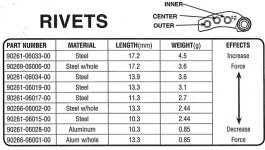

if you were happy with the sleds performance, you need to determine what those rivets were prior to removal so you can replace them with the same weight.

theres a good read in the tech pages, i believe, that will show the different rivets as well as the removal and install procedure.

those apear to be heavily loaded, or installed wrong. cant tell by the pics but something just doesnt look right.

if you were happy with the sleds performance, you need to determine what those rivets were prior to removal so you can replace them with the same weight.

theres a good read in the tech pages, i believe, that will show the different rivets as well as the removal and install procedure.

Might not be a bad idea to weigh them before you take the rivets out

biglsells

VIP Member

Was not happy at all with the sleds performance, would not go over 50. I'll check the tech section and see what it says, where to buy weights, etc. thanks!

biglsells

VIP Member

ok from what I gather from the tech pages, if I were going to keep these weights I would drill these rivets out and replace them but since I am not using these weights again I just need to purchase rivets and put them in my new weights.

I have read a few posts about people using button head machine screws, washers and jam nuts that match the weight of the rivets, can anyone explain this process better? It sounds like it would make life easier for changing tuning easily but I can't find many posts or pics of doing this (picture is worth 1000 words for me)

I have read a few posts about people using button head machine screws, washers and jam nuts that match the weight of the rivets, can anyone explain this process better? It sounds like it would make life easier for changing tuning easily but I can't find many posts or pics of doing this (picture is worth 1000 words for me)

biglsells

VIP Member

Uhg, sorry for multiple posts, still reading and learning. According to my manual it says I need 90261-06015 2.4 gram outer river and 90261-06034 3.6 gram inner river. Assuming the outer rivet (lighter one) is where I have the arrow drawn to? If so, going to the hardware store to see if I can make my own.

Attachments

If the arms are worn that much I would think the rollers are bad too.

if you dont have an accurate gram scale, your wasting your time, in my opinion.

you wont find anything that i am aware of at a hardware store, unless you go with the nut and bolt theory, along with the washers and loctite.

do not underestimate the power of the centrifugal force in your clutch spinning at nearly 10,000 rpm. yes, the rivets can be spendy, they are a pain to remove and install, but they stay put when done correctly and they maintain some sort of balance.

aviation buck rivets can be substituted for oem rivets if you have access to them. you will want the flush type rivets, but you will still need a gram scale.

you are correct on that being the outer hole. keep asking questions and dont be shy, lots of good teachers around here.

short cuts on clutch components is not a good idea in my book.

you wont find anything that i am aware of at a hardware store, unless you go with the nut and bolt theory, along with the washers and loctite.

do not underestimate the power of the centrifugal force in your clutch spinning at nearly 10,000 rpm. yes, the rivets can be spendy, they are a pain to remove and install, but they stay put when done correctly and they maintain some sort of balance.

aviation buck rivets can be substituted for oem rivets if you have access to them. you will want the flush type rivets, but you will still need a gram scale.

you are correct on that being the outer hole. keep asking questions and dont be shy, lots of good teachers around here.

short cuts on clutch components is not a good idea in my book.

It looks like the ramp of your weight may have a flat spot worn in it just above where the rivet head is worn down. Since you mention the other two weights are worse, and that you have new weights with empty holes, I'd call your local dealers in Grand Rapids to pick up the correct rivets (looks like you already have the numbers), or if you have time order them online from a Yamaha dealer (check TY advertisers). You can probably find them for a buck or two each (sounds expensive for a rivet, but only 6 are needed).

Also, as SXR1000 notes, the rollers may be bad as well. Also, check all of the bushings for slop/wear/uneven wear (weights, rollers, as well as the cover bushing and sliding sheave bushing). The bushings should slide easily on their shafts, with very little rock back and forth, the shop manual may have wear specs.

Also, as SXR1000 notes, the rollers may be bad as well. Also, check all of the bushings for slop/wear/uneven wear (weights, rollers, as well as the cover bushing and sliding sheave bushing). The bushings should slide easily on their shafts, with very little rock back and forth, the shop manual may have wear specs.

biglsells

VIP Member

Thanks for the good advice, I think I will pass on the bolt/nut idea. I do have a gram scale for cooking but if the rivets are that cheap why bother right? I've already replaced the rollers / bushings so its down to these weights, after that this thing should be totally rebuilt. Once I put the new rivets in can I peen them with a hammer or vice to lock them in place? (If it we a "normal" rivet it would have a hole and I could use a rivet gun but, alas, thats not the case).

staggs65

Moderator

it is a "normal" rivet. the ones with holes that you use a rivet gun are pop rivets

biglsells

VIP Member

hehe, I guess I should have said normal to what I am used to working with  Got them ordered, less than a dollar each.

Got them ordered, less than a dollar each.

Got them ordered, less than a dollar each.

Got them ordered, less than a dollar each.Hi guys. Quick question. I have a 94 vmax 500. I just put a 600 motor in if from the same year. I reused the 500 primary clutch. I know most of the parts look the same on the parts diagram. Except the rivets. Do the rivers change between 500 and 600? I've done a lot of reading and I'm confused. Do you have different rivets on the tip of the weight than on the inside? This is the site I use for part numbers. http://www.alljet.com/pro_parts/yamaha_v-max_snowmobile_oem_parts_diagrams_fiche.html

Can someone please tell me the exact part numbers for the rivets I need for a 94 vmax 600 using the site above? And what part number rivet goes on the tip of the weight and on the inside? And what does ap and std mean beside the part numbers? And why are the rivets on the diagram all in mm? thanks

Can someone please tell me the exact part numbers for the rivets I need for a 94 vmax 600 using the site above? And what part number rivet goes on the tip of the weight and on the inside? And what does ap and std mean beside the part numbers? And why are the rivets on the diagram all in mm? thanks

A couple of bucks

VIP Member

What elevation are you at?

A couple of bucks

VIP Member

A couple of bucks

VIP Member

Probably an engineer though it would be better.And why are the rivets on the diagram all in mm?