you could always use an angle gauge from the hardware store.

Been a while since I've updated this. My father took over the painting which I'm happy and grateful for. He's almost done clear coating that.

Heatshields installed on silencer and pipe with new straps and allen head plated bolts/washers:

Tuner skis with Yamaha P/N (Woody) wearbar only and Stud Boy 4.5" carbide. The Stud Boy's fit terrible. Had to bend them and grind the sides of them to fit into the ski. These were made for this ski P/N (SMA-8JHDS-00-00). The Yamaha P/N fit fine. Some before/after photos of them, and installed. Think I decided on the carbides on inside after reading some more threads on the 2 stroke side. I appreciate everyone's input though! Hell, maybe I'll swap the skis over in the same day and see how they are on the same trail conditions reversed. Going to be a lot more bite than the stock setup I thinks.

Heatshields installed on silencer and pipe with new straps and allen head plated bolts/washers:

Tuner skis with Yamaha P/N (Woody) wearbar only and Stud Boy 4.5" carbide. The Stud Boy's fit terrible. Had to bend them and grind the sides of them to fit into the ski. These were made for this ski P/N (SMA-8JHDS-00-00). The Yamaha P/N fit fine. Some before/after photos of them, and installed. Think I decided on the carbides on inside after reading some more threads on the 2 stroke side. I appreciate everyone's input though! Hell, maybe I'll swap the skis over in the same day and see how they are on the same trail conditions reversed. Going to be a lot more bite than the stock setup I thinks.

All new suspension bolts/bushings/heims are set ready to go on and grease. New exhaust springs and gaskets ready to go on. Cleaned up the belly pan area and engine since I had space. I wouldn't be happy with it unless I could pull it all out and sand blast it, but with the current access I have it's ok.

Cleaned up both primary and secondary sheaves. Also ordered some secondary shims to get my belt up a little more in the secondary.

Will also be getting some tight tolerance shims tomorrow for the upper shock mounts (https://www.mcmaster.com/90214a422), the new replacement clevis' that came on the rebuild from Hygear have 2-2.5mm of play in them to the bushing. Will be evenly spacing them to center the shock up to the bulkhead. Stock shocks that came off had about a 1mm gap, I'll see how they line up to the trailing arms and go from there.

Getting ready for a trip leaving next Thursday, hope to get er ready! Haven't touched the skid, will grease it and wait to rebuild it for the summer.

Pipe straps I used: https://www.mcmaster.com/6898k74

Replacement cotter pins (seem ok, yet to install): https://www.mcmaster.com/98350a210

Replacement cotter pins (seem ok, yet to install): https://www.mcmaster.com/98350a210

Vincent

New member

Nice build, keep it commin

A couple of bucks

VIP Member

What did you decide on insulation between the the pipe and cover?

Yamahakid01

New member

Can I ask? I read you entire post and maybe I missed it some place, how are you cleaning these parts? They look really clean like ultra sonic clean! or maybe its just the pictures.

I used this stuff: https://www.mcmaster.com/93315k51

Traced the stock insulation liners, and cut out one set of each, let me double check what side I put the new vs. oem on tonight (I can't remember off the top of my head...). I first tried 2 layers of the new stuff sandwiching the stock but was too thick to get the shields to attach correctly. I don't really trust the stuff I bought alone without the oem, I just don't know the specs of the oem material to replace it exactly, and this stuff I bought has silica 'beads' in it (kind of gritty when cutting it). It would probably be fine rated for 2000*f but .

.

THe clutch parts were cleaned in a parts washer by hand. The above bolts and stuff in the last post are actually all new, the originals had a ton of rust (shown earlier). I tried to clean some in an ultrasonic then wirewheel just to see but the zinc coating was worn off and would just rust again. The radius rods and trailing arms were sand blasted. The steering arms I just first used the ultrasonic, then used green stochbright.

Btw, OEM stuff is expensive, but I found Partzilla is cheaper than dealer parts fiches. Also this thread helped me on bolts for stainless replacements: https://www.venturerider.org/forum/showthread.php?45627-How-to-find-Yamaha-bolt-sizes

Traced the stock insulation liners, and cut out one set of each, let me double check what side I put the new vs. oem on tonight (I can't remember off the top of my head...). I first tried 2 layers of the new stuff sandwiching the stock but was too thick to get the shields to attach correctly. I don't really trust the stuff I bought alone without the oem, I just don't know the specs of the oem material to replace it exactly, and this stuff I bought has silica 'beads' in it (kind of gritty when cutting it). It would probably be fine rated for 2000*f but

.

.THe clutch parts were cleaned in a parts washer by hand. The above bolts and stuff in the last post are actually all new, the originals had a ton of rust (shown earlier). I tried to clean some in an ultrasonic then wirewheel just to see but the zinc coating was worn off and would just rust again. The radius rods and trailing arms were sand blasted. The steering arms I just first used the ultrasonic, then used green stochbright.

Btw, OEM stuff is expensive, but I found Partzilla is cheaper than dealer parts fiches. Also this thread helped me on bolts for stainless replacements: https://www.venturerider.org/forum/showthread.php?45627-How-to-find-Yamaha-bolt-sizes

Last edited:

Sorry 01, I edited my last post if you didn't see it, I think we posted at the same time.

I've actually thought about getting a plating/anodizing kit to try to replate stock stuff after blasting, I'm guessing that would be much cheaper than buying new in the long run.

For the insulation I put the new stuff against the pipe (hot side) and the original stuff towards the heat shield.

Dad finished up the painting and put the 2001 stickers on, turned out so good!

Last Sunday spent 11 hours in the garage getting this back together! Went smoothly besides the lower radius rod bolt holes for the aftermarket trailing arm not being aligned right, had to file it out a little to fit (also adjust the rod out a few turns from what I had written down from the OEM arm).

The lower PTO side exhaust manifold bolt is a total PITA to get in, when starting it you can't even put a socket on it because it touches the manifold. Had to get in an awkward angle to get it started then put an open end wrench on it then was able to put a socket on it. I needed 3 different socket setups to torque the mainfold on... Looks good though!

Alignment was all good after assembly, didn't need to adjust anything!

Absolutely love the '01 stickers on the blue paint, I can't recall seeing this before but it totally matches the strobes on the hood graphics!

Went up to Lakewood/Mountain WI area this weekend and it ran perfect. Will tear into the skid in Spring and hopefully finish this multi-year build...

I like the tuner ski setup, it didn't totally eliminate darting but much much better than before. I think I'll do the shim trick on the rubbers and that should eliminate it totally. Steering effort isn't noticeably higher than before but handles good. Front suspension felt smooth, went for a ride Saturday night after all the traffic during the day (was rough) and I can tell the skid is the weak point right now. When I sit on the sled I can hear the skid squeak... Looking forward to rebuilding it.

The lower PTO side exhaust manifold bolt is a total PITA to get in, when starting it you can't even put a socket on it because it touches the manifold. Had to get in an awkward angle to get it started then put an open end wrench on it then was able to put a socket on it. I needed 3 different socket setups to torque the mainfold on... Looks good though!

Alignment was all good after assembly, didn't need to adjust anything!

Absolutely love the '01 stickers on the blue paint, I can't recall seeing this before but it totally matches the strobes on the hood graphics!

Went up to Lakewood/Mountain WI area this weekend and it ran perfect. Will tear into the skid in Spring and hopefully finish this multi-year build...

I like the tuner ski setup, it didn't totally eliminate darting but much much better than before. I think I'll do the shim trick on the rubbers and that should eliminate it totally. Steering effort isn't noticeably higher than before but handles good. Front suspension felt smooth, went for a ride Saturday night after all the traffic during the day (was rough) and I can tell the skid is the weak point right now. When I sit on the sled I can hear the skid squeak... Looking forward to rebuilding it.

A couple of bucks

VIP Member

Lakewoods as in ... lake Namacogin? I don't think that is the correct spelling for that lake though.

The northern part of Oconto county, the trails go through public national forest Chequamegon-Nicolet. The lake the photos are on is Waubee.

Printed out the manual at work as my regular service manual has pages tearing out and the binding is cracking. Used some Office Depot sheet protectors and put them in a 3 ring binder. If anyone wants to do this I suggest:

- Print the front and back covers separate, the PDF manual doesn't put the blank sides on those so everything is 1 sheet off of the printed manual.

- Be careful of the pull-out sheets, for whatever reason the printer didn't print the pull-out long wiring diagram sheet.

- Get a 6-pack and some tunes, this is boring as all hell.

Just posting an update. I was never able to ride the sled last season (20-21). I didn't touch it at all until about a month ago.

Retorqued everything on the front end since it was ridden after the assembly of the redone shocks and trailing arms. Redid alignment, the right trailing arm camber was way out (I see in post #53 I said I had to adjust the radius rod out, must have settled or something as I had to adjust it in a few turns to get back to zero). I also realized when I installed the new shocks the fill port for the nitrogen was facing down, just rotated it around so they are facing up.

Was able to go for a short ride this past weekend, about 35-40 miles. I was using the same 2 year old gas just trying to burn it out. I went from the marker bar just under the half mark to running on low fuel light. I was riding a bit hard the first 3/4 until I realized how fast the gas was being used. It ran good, didn't seem too rich at all. Might be bad old gas, but a carb rebuild kit might not be a bad idea? Part of me wanted to ride it with new gas and see how the mileage is.

I also still have all the aluminum rebuilt shocks, new bushings, 4th wheel kit, rear wheels to rebuild the skid I've had for years now. I swear this off-season it'll finally happen!

Retorqued everything on the front end since it was ridden after the assembly of the redone shocks and trailing arms. Redid alignment, the right trailing arm camber was way out (I see in post #53 I said I had to adjust the radius rod out, must have settled or something as I had to adjust it in a few turns to get back to zero). I also realized when I installed the new shocks the fill port for the nitrogen was facing down, just rotated it around so they are facing up.

Was able to go for a short ride this past weekend, about 35-40 miles. I was using the same 2 year old gas just trying to burn it out. I went from the marker bar just under the half mark to running on low fuel light. I was riding a bit hard the first 3/4 until I realized how fast the gas was being used. It ran good, didn't seem too rich at all. Might be bad old gas, but a carb rebuild kit might not be a bad idea? Part of me wanted to ride it with new gas and see how the mileage is.

I also still have all the aluminum rebuilt shocks, new bushings, 4th wheel kit, rear wheels to rebuild the skid I've had for years now. I swear this off-season it'll finally happen!

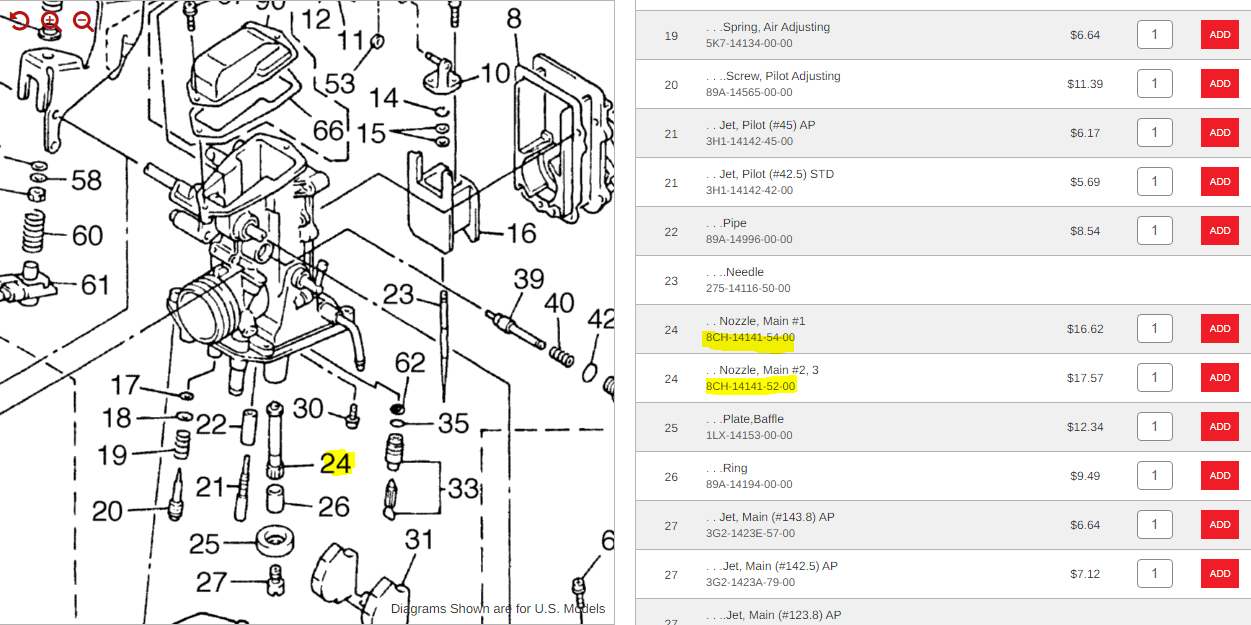

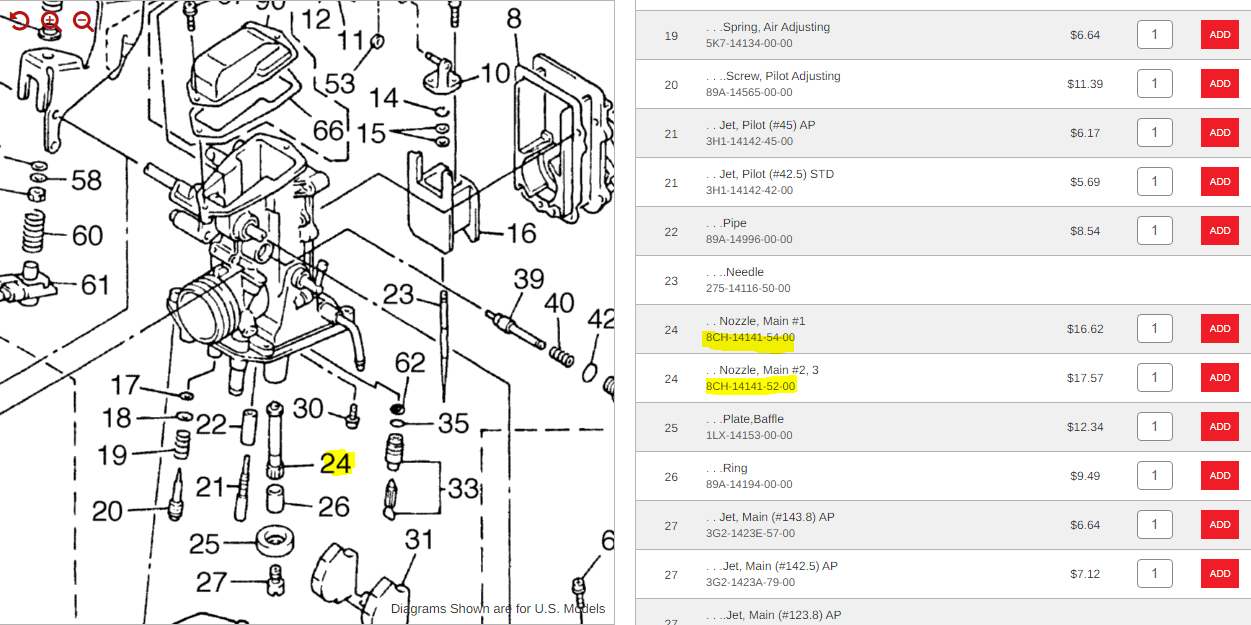

Have a carb rebuild kit coming (https://www.allballsracing.com/26-10039.html) and new main nozzles.

Looks like carb 1 has a different part than 2 & 3. Why would that be? I know they have different main jets, but why would the nozzle be different?

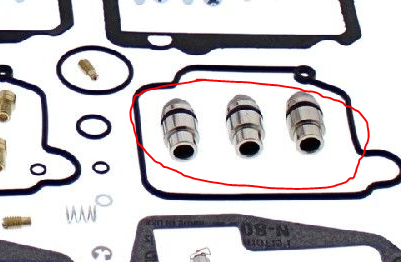

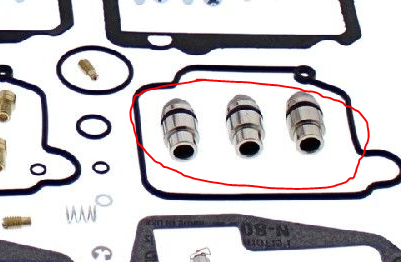

Might be dumb, but I can't figure out what these are?

Looks like carb 1 has a different part than 2 & 3. Why would that be? I know they have different main jets, but why would the nozzle be different?

Might be dumb, but I can't figure out what these are?

looks like the filters above the needles.