Hello,

Was wondering if anyone has ever had this issue before? My sled started running on one cylinder at idle only last year,once off idle the midrange and full throttle seems fine.

I clean my carbs every year and did it twice this year for this specific reason thinking the idle circuit was plugged. It has spark on both holes and i replaced the spark plugs as well. When the mag side plug wire is pulled it makes a very slight difference in idle speed but when the PTO side is pulled it dies right away. In the past I had a similar problem but the issue was one of the slides for the throttle came out of adjusment and that was causing weird issues with idle but i am positive thats not the problem now.

I did a search on this and the only one I found that was having similar issues was a VK540 fan and it turned out his sled had a bent ring! I think his compression was 105 psi in each hole,he said his crank seals were bad too.

I have not done a comp test yet but will do that shortly and post reults.

I am the second owner of this machine owned it since 99 had 1900 miles on it when i got it now it has 7000. At about 5000 miles I put new rings in it (hope I didn't muck anything up) and took 1 layer of the head gasket out. Compression test after work was done was about 145psi in each hole.

Any advice,ideas welcomed Thanks

Was wondering if anyone has ever had this issue before? My sled started running on one cylinder at idle only last year,once off idle the midrange and full throttle seems fine.

I clean my carbs every year and did it twice this year for this specific reason thinking the idle circuit was plugged. It has spark on both holes and i replaced the spark plugs as well. When the mag side plug wire is pulled it makes a very slight difference in idle speed but when the PTO side is pulled it dies right away. In the past I had a similar problem but the issue was one of the slides for the throttle came out of adjusment and that was causing weird issues with idle but i am positive thats not the problem now.

I did a search on this and the only one I found that was having similar issues was a VK540 fan and it turned out his sled had a bent ring! I think his compression was 105 psi in each hole,he said his crank seals were bad too.

I have not done a comp test yet but will do that shortly and post reults.

I am the second owner of this machine owned it since 99 had 1900 miles on it when i got it now it has 7000. At about 5000 miles I put new rings in it (hope I didn't muck anything up) and took 1 layer of the head gasket out. Compression test after work was done was about 145psi in each hole.

Any advice,ideas welcomed Thanks

Just did the compression test it has 144psi on PTO side and 31psi on MAG side WOW!!!

I had no idea it was that bad and glad I didn't get talked into going on a pretty decent ride the other weekend, looks like i'll be tearing this thing down.

I just can't believe it SEEMS to run so good at higher RPMs .

Any advice on the best way to check crank seals?

Hope it's just a blown gasket or something cheap like that,I really don't want to take the bottom end apart if I don't have to.

THIS THING HAS NEVER LET ME DOWN BEFORE!!

I had no idea it was that bad and glad I didn't get talked into going on a pretty decent ride the other weekend, looks like i'll be tearing this thing down.

I just can't believe it SEEMS to run so good at higher RPMs .

Any advice on the best way to check crank seals?

Hope it's just a blown gasket or something cheap like that,I really don't want to take the bottom end apart if I don't have to.

THIS THING HAS NEVER LET ME DOWN BEFORE!!

Last edited:

yamahamark

Member

Wow is right that's crazy low. Check the seals by spraying starting fluid on them while running. It's also a good way to check all your gaskets. If they leak it will rev up.

A couple of bucks

VIP Member

Holy moly. I haven't seen that cranky baby on here in quite some time.

super1c

Super Moderator

At least time to tear top end down for sure.

That cranky baby and his sister are the reason I can't have fun with my yamaha very much anymore lol

Trying to figure out how to post a couple of pics from my phone, but no luck!

A couple of bucks

VIP Member

Hit the....go advance... At the lower right of the box your typing in. Then .... Add image.Trying to figure out how to post a couple of pics from my phone, but no luck!

Can't find "add image" anywhere in the go advanced option.

Is it one of the little icons on the top?

Anyway my MAG side piston is missing a decent size chunk out of it, the cylinder is fubared, the head seems ok besides a few little nicks in the combustion chamber.

I can't believe how well this thing ran in this condition!!!

The only thing I really noticed was the idle issue.

It looks more like breakage then burn down to me but as soon as I get photo's up maybe you can help decide.

Starting to think that I've gone this far so might as well do crank seals while I'm in there?

7000 miles

Thanks

Is it one of the little icons on the top?

Anyway my MAG side piston is missing a decent size chunk out of it, the cylinder is fubared, the head seems ok besides a few little nicks in the combustion chamber.

I can't believe how well this thing ran in this condition!!!

The only thing I really noticed was the idle issue.

It looks more like breakage then burn down to me but as soon as I get photo's up maybe you can help decide.

Starting to think that I've gone this far so might as well do crank seals while I'm in there?

7000 miles

Thanks

A couple of bucks

VIP Member

Sorry it's ..... Manage attachments

If I were to go with a 94-95 head gasket instead of taking a layer out of the 96 one would it have lower compression or be about the same?

Starting to wonder if it was a little overkill?

I always run non oxy premium.

Starting to wonder if it was a little overkill?

I always run non oxy premium.

yamahamark

Member

Going to a 95 head gasket would raise your compression.

Almost looks like that cylinder was running a little on the lean side. Other cylinder looks about spot on.

Almost looks like that cylinder was running a little on the lean side. Other cylinder looks about spot on.

Going to a 95 head gasket would raise your compression.

Almost looks like that cylinder was running a little on the lean side. Other cylinder looks about spot on

Are you saying that using a 94 to 95 head gasket will produce more compression than doing the "head gasket mod" to a 1996 gasket?

I'm talking about taking 1 layer out of the 3 that make up a 96 gasket, that is what I did when I reringed it.

Attachments

Last edited:

A couple of bucks

VIP Member

How thick is your modified 96 XT gasket.

Head gasket thickness by year

1994-95' .6mm

1996 1.4mm

1995-96 Mountain max 600's were .8mm

Head gasket thickness by year

1994-95' .6mm

1996 1.4mm

1995-96 Mountain max 600's were .8mm

I was actually just out in the garage and measured it because I found those stock specs!

It measures out at .48mm. Hopefully thats not too excessive, what do you think about the piston wash in the good cylider?

I did the mod probably 5-6yrs ago and had 145psi of comp. the good one still has 144psi.

Thanks Tony

It measures out at .48mm. Hopefully thats not too excessive, what do you think about the piston wash in the good cylider?

I did the mod probably 5-6yrs ago and had 145psi of comp. the good one still has 144psi.

Thanks Tony

A couple of bucks

VIP Member

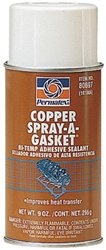

When your ready to torque the head down, do this. Warm that gasket up on the garage stove/heater until it's to hot to touch. Spray 2 coats of Permatex Copper spray gasket onto both sides. The hot gasket will make the spray flash-over instantly and another can be applied immediately.

Attachments

Thanks for all the help Dannyboy.

I found a guy nearby that has a used jug and piston for $160 think I might just go that route if it looks good, I think I'll just do crank seals to be safe.

Anything else you can think of?

I was thinking about upgrading reeds, I keep hearing about spacers and stopper notch? I'll have to look into that some more.

I found a guy nearby that has a used jug and piston for $160 think I might just go that route if it looks good, I think I'll just do crank seals to be safe.

Anything else you can think of?

I was thinking about upgrading reeds, I keep hearing about spacers and stopper notch? I'll have to look into that some more.

A couple of bucks

VIP Member

You can't notch the stops on the 94-96 cages. Spacers would be harder to find as the bolt pattern on the 94-96 cages are different than the 97 & up.

I did put Carbon Tech reeds in my 96 XT6.

http://www.totallyamaha.net/forums/threads/97649-96-XT6-to-144

I did put Carbon Tech reeds in my 96 XT6.

http://www.totallyamaha.net/forums/threads/97649-96-XT6-to-144

Thanks for the link,lot of cool mods you did to that vmax,I like the grease zerks on the scissors!

Was out in the garage with a buddy of mine that is going to set me up with the parts I need and I was looking at the failed piston.

What I saw pretty much nailed it down to why this happened, the top ring on the piston spun and the end caught the transfer port!

He said they pretty much are not able to spin once assembled but it was running fine for several years after I reringed it, he gave me a good tip for assembly to make sure this doesn't happen again.

We decided the crank seals are good by looking at the bearings on the connecting rod journals,he says they will turn bluish if there was a lean condition from bad seals.

I decided not to go with used jug&piston and he will look into some performance reeds for me.

Tanks for all the help and I hope this will help someone out in the future.

Tony

Was out in the garage with a buddy of mine that is going to set me up with the parts I need and I was looking at the failed piston.

What I saw pretty much nailed it down to why this happened, the top ring on the piston spun and the end caught the transfer port!

He said they pretty much are not able to spin once assembled but it was running fine for several years after I reringed it, he gave me a good tip for assembly to make sure this doesn't happen again.

We decided the crank seals are good by looking at the bearings on the connecting rod journals,he says they will turn bluish if there was a lean condition from bad seals.

I decided not to go with used jug&piston and he will look into some performance reeds for me.

Tanks for all the help and I hope this will help someone out in the future.

Tony