My 98 xtc see to have an issue with he belt tension. I can hear it squealing when sitting at idle and has a tendency to start to walk away. I went throught the pains taking act of setting back the motor to the specs in the book but it still does it. Brand new belt. No shims in secondary. Do I go beyond the specs or what am I missing?

A couple of bucks

VIP Member

REARSPROCKET

New member

Your adjustment bolts may have the tips worn off making them shorter and tightening the belt. Check your belt deflection and if it's tight pull the secondary bolts out and see if the tips are worn off. Just went through the same issue on my buddies 97 SX700, there was almost a 1/4" of the bolt tips worn off. After installing new bolts the belt was too loose and we had to add a 1mm and a .5mm shim to each bolt to get the deflection right for a new 8DN. Adding shims shortens the bolts and TIGHTENS the belt.

Last edited:

A couple of bucks

VIP Member

I should really read things fully before posting. And shims do indeed narrow the sheave up. Making the belt squeal. Sprocket is correct. Sorry for my previous post.

Replacement of the adjustment bolts is probably needed.

Replacement of the adjustment bolts is probably needed.

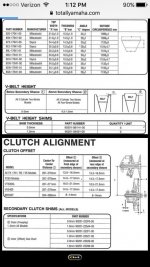

View attachment 66186

Belt height shims need to be added.

But adding shims reduces the secondary width right? That would tighten in the belt wouldn't it? The height is about 1mm above the edge of the secondary. And that's in spec.

But adding shims reduces the secondary width right? That would tighten in the belt wouldn't it? The height is about 1mm above the edge of the secondary. And that's in spec.

Sorry I wrote this before I saw your reply. I tried to delete it but couldn't ��

Your adjustment bolts may have the tips worn off making them shorter and tightening the belt. Check your belt deflection and if it's tight pull the secondary bolts out and see if the tips are worn off. Just went through the same issue on my buddies 97 SX700, there was almost a 1/4" of the bolt tips worn off. After installing new bolts the belt was too loose and we had to add a 1mm and a .5mm shim to each bolt to get the deflection right for a new 8DN. Adding shims shortens the bolts and TIGHTENS the belt.

My height is 1mm above the edge of the plate. Should I still look at the bolts? It feels to me like the deflection is way too tight. Barely moves.

My height is 1mm above the edge of the plate. Should I still look at the bolts? It feels to me like the deflection is way too tight. Barely moves.

Ok so I just went and measured again and I'm about 2mm above the edge. I looked real close and saw there was still a shim on each bolt. I'm taking them all out now. Thread is 14.75mm. How long should they be?

Jack99

Member

Silly question for some folks but did you install a pure Yamaha brand belt on your sled?

Reason I ask is because when I use my backup belt, it squeaks at idle and turns its track when using its rear stand as well. If wondering, my backup belt is listed as a non-Yamaha "clone" is compatible with Yamaha belt part number. But, its clone belt (from Amazon) isn't 100% exact as pure Yamaha brand.

No worries, my pure Yamaha belt arrived yesterday. Will use my clone belt for a few more remaining end of season rides..

Hope this helps as well.

Reason I ask is because when I use my backup belt, it squeaks at idle and turns its track when using its rear stand as well. If wondering, my backup belt is listed as a non-Yamaha "clone" is compatible with Yamaha belt part number. But, its clone belt (from Amazon) isn't 100% exact as pure Yamaha brand.

No worries, my pure Yamaha belt arrived yesterday. Will use my clone belt for a few more remaining end of season rides..

Hope this helps as well.

Last edited:

Silly question for some folks but did you install a pure Yamaha brand belt on your sled?

Reason I ask is because when I use my backup belt, it squeaks at idle and turns its track when using its rear stand as well. If wondering, my backup belt is listed as a non-Yamaha "clone" is compatible with Yamaha belt part number. But, its clone belt (from Amazon) isn't 100% exact as pure Yamaha brand.

No worries, my pure Yamaha belt arrived yesterday. Will use my clone belt for a few more remaining end of season rides..

Hope this helps as well.

Yup it's a genuine yamaha. I took the second shims out and it seemed to work. Won't really know until I get it warmed up. Doesn't usually squeak until the motor gets hot.

REARSPROCKET

New member

Not sure on new bolt length because we used them, but new or unworn bolts have a tip with no threads on it about an 1/8 or 3/32 long. If your bolts dont have a tip on the end and the threads go all the way to bottom it's worn. It depends on which belt your running and if its worn where you need to be with deflection. The 8DN like to have the outer ribs above sheeve and the older 8CH likes to be level or below.

Not sure on new bolt length because we used them, but new or unworn bolts have a tip with no threads on it about an 1/8 or 3/32 long. If your bolts dont have a tip on the end and the threads go all the way to bottom it's worn. It depends on which belt your running and if its worn where you need to be with deflection. The 8DN like to have the outer ribs above sheeve and the older 8CH likes to be level or below.

Oh Damn! There's definitely no tips. Threaded right to the end. I did take out the second shims (I think I left them originally because I thought they were washers for the bolt heads) and now I am just under 1mm above the edge. The belt I bought I'm pretty sure is the 8D. I fired it up and took it across the lawn and it didn't squeal but sometimes it doesn't until after everything gets hot. Hopefully Im good for this weekend and Ill get new bolts ordered. Ill probably have to put all the shims back in that I removed. Fingers crossed. Thanks Guys!

REARSPROCKET

New member

Here is the part number for the bolts 90105-06734-00

1mm Shims 90201-06431-00

.5mm Shims 90201-061H1-00

I'd probably order more 1mm shims you'll probably need them with new bolts, Good Luck

1mm Shims 90201-06431-00

.5mm Shims 90201-061H1-00

I'd probably order more 1mm shims you'll probably need them with new bolts, Good Luck