Drwe

Member

- Joined

- Nov 28, 2021

- Messages

- 75

I just bought a '98 vmax 700 xtcd, the reverse doesn't want to engage. No grinding, nothing. Previous owner said reverse "was working great to take it off the trailer last week."

When I unbolt one of the rod eyes, and I actuate the bottom part of the linkage by hand, it moves pretty freely. Should I be feeling spring pressure from inside the chain case?

Also, where can I get the service manual for this machine?

Full disclosure, this is my first sled.

When I unbolt one of the rod eyes, and I actuate the bottom part of the linkage by hand, it moves pretty freely. Should I be feeling spring pressure from inside the chain case?

Also, where can I get the service manual for this machine?

Full disclosure, this is my first sled.

welcome to the site!

yes you should be feeling resistance.

this link will show you the steps on the install witch should help you on the dissasembly to see what is going on. could be the pins on the fork are worn out.

as to a manual, as a perk of being a vip here on ty, as a moderator i can send you any manual you need and you help keep a great site going.

here is link to becoming vip if you are interested.

yes you should be feeling resistance.

this link will show you the steps on the install witch should help you on the dissasembly to see what is going on. could be the pins on the fork are worn out.

as to a manual, as a perk of being a vip here on ty, as a moderator i can send you any manual you need and you help keep a great site going.

here is link to becoming vip if you are interested.

Drwe

Member

- Joined

- Nov 28, 2021

- Messages

- 75

Thanks, yeah I just paid for VIP, waiting for the badge.

Drwe

Member

- Joined

- Nov 28, 2021

- Messages

- 75

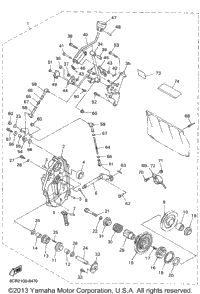

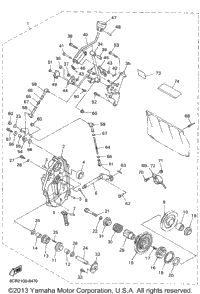

Also wondering if there is a chaincase gasket I should be ordering, the previous owner appears to have used some gasket maker in conjunction with the original gasket. I don't see one in this diagram.

www.yamahapartshouse.com

www.yamahapartshouse.com

1998 Yamaha VMAX 700 XTC DELUXE (ELEC START) (VX700XTCDB) Alternate Drive Std On Xtcdb

Shop online for OEM Alternate Drive Std On Xtcdb parts that fit your 1998 Yamaha VMAX 700 XTC DELUXE (ELEC START) (VX700XTCDB), search all our OEM Parts or call at (231)737-4542

it uses the same gasket as the non reverse chaincase. i have never had to use silicone on one yet.

Drwe

Member

- Joined

- Nov 28, 2021

- Messages

- 75

I opened up the chaincase, looks like all the sprockets and chain were replaced at some point. The only thing I see is that the shift fork teeth have worn down considerably on one side. Reassembling the cover with the shift forks in place, I can now feel the spring pressure. Was it just not assembled properly before? What could cause this kind of wear on the shift forks? Do you think I should try flipping them around to see if it'll help or should I just replace them?

It also looks like there is a crack in the chaincase cover, which has been sealed by some kind of gasket maker or similar compound. Should I go to the expense of replacing the cover of it wasn't leaking? Would epoxy such as JB weld be a better repair job?

Pictures:

drive.google.com

drive.google.com

It also looks like there is a crack in the chaincase cover, which has been sealed by some kind of gasket maker or similar compound. Should I go to the expense of replacing the cover of it wasn't leaking? Would epoxy such as JB weld be a better repair job?

Pictures:

Totallyamaha - Google Drive

drive.google.com

drive.google.com

wow those pins are worn pretty good on the reverse fork. i would just replace them.

jb weld would do a better job but if it is not leaking, i would leave it along.

jb weld would do a better job but if it is not leaking, i would leave it along.

Drwe

Member

- Joined

- Nov 28, 2021

- Messages

- 75

I filed off the burr on each fork and it looks like there's about 75% of the material remaining (pics added). The round good side is the part that pulls the reverse gear so the flat side shouldn't be a problem. Going to try and run it like this I think.wow those pins are worn pretty good on the reverse fork. i would just replace them.

jb weld would do a better job but if it is not leaking, i would leave it along.

Does JB weld adhere well to this cast (aluminum?) stuff?

if you use jb weld for aluminum it should work if all the prep is correct.

super1c

Super Moderator

Used JB weld on those covers with great success. Punched holes through the cover when gear bolt backed out of drive. Just clean good.