supercharged111

Member

And ported and gutted airbox vs me. I am curious, Bender is the golden standard for pipes. How much of a difference is there between them and the SLPs? Was their real appeal a wider powerband and a smidge more top end? Those 8CR with no rivets are 42g as they sit. I feel I ought to hold off shotgunning any more clutch parts until I get my secondary in order. Quick easy and unlimited adjustability simply can't be beat. I may have to give those guys an email.

It looks like Thunder Products doesn't make the Heavy Hitter weights in the model I used anymore. I used a base weight of 38 grams then added 7.5 grams in the tip using a long cover silver/white/silver spring

I always used Bender products back then but SLP pipes are very good as well.

I always used Bender products back then but SLP pipes are very good as well.

supercharged111

Member

These new secondary bushings are TIGHT. I got the one in the sheave to play ball I think. There is zero slop with the new bushings, I'm hoping they wear in a little with use. I swapped out the bushing in the Bender helix with the old sheave bushing. That was less sloppy in the helix and proved I could fit a Yamaha bushing in there without fear of ruining the new one. But the new one is so tight I can't get the helix on at all. Anyone have any pointers here? I used a socket and my press and it didn't fight me or mushroom at all from what I could tell. I wiped the aluminum clean with a green scotch Brite so nothing on the surface to choke down the diameter of the bushing. I can squeeze a naked bushing on the shaft and it's very tight there. Like it was made with slightly too small of an ID? Or made with a layer that's either going to sacrifice itself or need to the exact size of the shaft on the clutch itself?

I have ran into this on both the primary and secondary bushings I have replaced recently(oem). I think Yamaha changed vendors and the tolerance is too tight. What I did was hand sand with emery cloth until they slide proper. I do have the correct Yamaha tools for pressing them on and have never tried your method with a socket

supercharged111

Member

I went back after the secondary sheave and hand squeezed it in 1 spot, rotated, and repeated in an effort to smoosh the new bushing out into the sheave more effectively . It worked! Got the thing loosened up to what I'd expect out of a new bushing.

supercharged111

Member

Went out Tuesday and spit the bushing right out. Pressed the old one in, went out yesterday, spit that one out too. Drove to my usual crack dealer and picked up a used low mile secondary from an 01 SX-R 600 which means I got a 47 degree helix to add to my mix. Came home, cleaned it up, and went out with the 8CR weights, no rivets, stock primary spring, stock secondary spring, and 47 degree helix. Not a whole lot different, would zing up around 9000 then about 60 would drop to 8500 and not go over 70 or so. Let off, get on it, no backshift no go. Swapped the helix for the RX1 unit. Theoretically should be close off the line, but allow more RPM up top vs the 47 degree unit. No change. Explodes out of the hole then done at 70. This was done right at sunset and about all that I'd hoped to accomplish. I just swapped out the 8CR weights for the 8DN-10 and plan to run them tomorrow. Thinking maybe I should start with a straight helix?

supercharged111

Member

Since I'll be waiting on shipping for more bushings I went and snagged a low mile secondary off an 01 SX-R 600 which also provided me with a 47 degree helix to add to my collection. With a straight helix the 8DN-10 seems to have a short lived, but not insignificant flare when you lay into it. It seemed to zing up around 9200 and then quickly settle in around 8500. The RX1 helix would take the flare and keep it under 9000, but it would lug to around 8400 by 60mph. North of 70 the RPM recovered and would stay right around 8800-8900 and this provided the highest top end speed in the heat of the day (it was high 40s today). I'm thinking of trying the stock weights tomorrow with the Bender helix as that combo had a flat shift curve if memory serves correct. It just has too low of RPM. I have a stiffer primary spring, 2 shims, and a stiffer secondary spring to throw at that to see what happens. My only concern there is efficiency. Right now I have 8DN-10 with no rivets, stock springs in both clutches, and an RX1 helix at 60 degrees. Only 1 way to find out I suppose.

supercharged111

Member

Also, how high can you spin this motor before you should be nervous?

The Red Heads seem to be ok up to around 9200 but really the pipes dictate what RPM you should run. The hp on most two strokes drops off dramatically if you rev them higher then the pipe manufactures have designed the pipes for. For example, if the pipes are designed for 8800 rpm you are far better off under revving to say 8600 rpm then over revving to 9000 rpmAlso, how high can you spin this motor before you should be nervous?

supercharged111

Member

The Red Heads seem to be ok up to around 9200 but really the pipes dictate what RPM you should run. The hp on most two strokes drops off dramatically if you rev them higher then the pipe manufactures have designed the pipes for. For example, if the pipes are designed for 8800 rpm you are far better off under revving to say 8600 rpm then over revving to 9000 rpm

I'm more asking from the perspective of where do they blow up? Since these combos need to be wrung out to fully characterize the shift curves. The combo in there now keeps it under 9000. . . in yesterday's conditions. It is noticeably happier at 8700-8800 than 8500 that's for sure.

supercharged111

Member

I just ordered some 8EK weights. Those look like they'll take away that flare initially but then let the RPM come in up top, sort of reversing what I saw with the straight helixes. I feel like a dual angle helix rather than a progressive might be the answer for the 8DN-10 if you could get that changeover point in the right spot. Probably take like 4 custom helixes to land just right there.

supercharged111

Member

Would it be correct to say that a larger roller would make everything happen later? I.E. if there's a shift in the RPM curve at some point, that that point gets moved to a higher speed with a larger roller?

supercharged111

Member

The Red Heads seem to be ok up to around 9200 but really the pipes dictate what RPM you should run. The hp on most two strokes drops off dramatically if you rev them higher then the pipe manufactures have designed the pipes for. For example, if the pipes are designed for 8800 rpm you are far better off under revving to say 8600 rpm then over revving to 9000 rpm

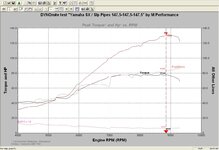

This dyno makes me think it's better to err on the high side than the low side as long as the bottom end will stay together.

I don't care about the numbers, just where the meat is at.

Peak Seeker

Member

- Joined

- Oct 2, 2025

- Messages

- 50

I put the same pipes on a sled I picked up a year ago.

The sled had a broke primary spring when I bought it so it was never 100% when it was in stock configuration.

I fought with the SLP pipes for many weekends. The clutch engagement seemed similar to yours, I'd hold it WOT amd it would wind up to about 100km/hr then the rpms would fade off to ~7800. I tried different weights and different rivets, jets, secondary settings and a different main spring.

Turns out my belt was just worn out.

I put a new belt on and set it up as SLP suggested and all was well.

Unfortunately I also bought them used so I didn't get the heat shields either. I tried no shields,things got a bit melted. I tried header/exhaust wrap and thay helped jut didn't complete solve the problem. I'll likely try to fab up some shields this fall.

The sled had a broke primary spring when I bought it so it was never 100% when it was in stock configuration.

I fought with the SLP pipes for many weekends. The clutch engagement seemed similar to yours, I'd hold it WOT amd it would wind up to about 100km/hr then the rpms would fade off to ~7800. I tried different weights and different rivets, jets, secondary settings and a different main spring.

Turns out my belt was just worn out.

I put a new belt on and set it up as SLP suggested and all was well.

Unfortunately I also bought them used so I didn't get the heat shields either. I tried no shields,things got a bit melted. I tried header/exhaust wrap and thay helped jut didn't complete solve the problem. I'll likely try to fab up some shields this fall.

have you looked at ceramic coating the pipes? i seem to remeber a lot of people doing that and not running heat shields back in the day.Unfortunately I also bought them used so I didn't get the heat shields either. I tried no shields,things got a bit melted. I tried header/exhaust wrap and thay helped jut didn't complete solve the problem. I'll likely try to fab up some shields this fall.

Peak Seeker

Member

- Joined

- Oct 2, 2025

- Messages

- 50

I haven't, I'll have to do some research into it.have you looked at ceramic coating the pipes? i seem to remeber a lot of people doing that and not running heat shields back in the day.

supercharged111

Member

My clutches are squeaky clean and I added a new belt, no change. I'll just reboot this season experimenting with clutching until I get somewhere.

supercharged111

Member

I'm starting to get the itch. Thinking I'll experiment with custom helixes this season, just need to figure out who it was that I called last year. These $300 triple pipes sure have gotten expensive. . .

Peak Seeker

Member

- Joined

- Oct 2, 2025

- Messages

- 50

I fired mine up and pulled it from the shed to the trailer so I got my first ride in already haha.I'm starting to get the itch. Thinking I'll experiment with custom helixes this season, just need to figure out who it was that I called last year. These $300 triple pipes sure have gotten expensive. . .

One of the next couple weekends I'm going to tackle fabricating some heat shields.

supercharged111

Member

I fired mine up and pulled it from the shed to the trailer so I got my first ride in already haha.

One of the next couple weekends I'm going to tackle fabricating some heat shields.

Do you have pics of what melted? The SLP instructions were written at a time when the bar was apparently quite low for such a thing.