chilli

New member

I have the tech sheet printed out, but I hear (and just read) about the confusion of adjusting, upsidedown valves, cable stretch etc.

My pipes are still off the machine, and was planning on doing the power valves, but have never done it.....

If I pull the cables out of the servo, and then re-install them without ever starting the engine, shouldn't everything be ligned up where they were before?

I dont want to start the engine without the pipes to get the actuator to move...

What to do, what to do

So seriously, how hard of a job is this?? Shouldn't it be easy to do?

Anyone have a better guide then whats in the tech section?

My Clymers manual doesn't have stuff about PV's

My pipes are still off the machine, and was planning on doing the power valves, but have never done it.....

If I pull the cables out of the servo, and then re-install them without ever starting the engine, shouldn't everything be ligned up where they were before?

I dont want to start the engine without the pipes to get the actuator to move...

What to do, what to do

So seriously, how hard of a job is this?? Shouldn't it be easy to do?

Anyone have a better guide then whats in the tech section?

My Clymers manual doesn't have stuff about PV's

mulderdad

New member

They are easy to do.

Yps

CHILLI, Is your sled electric start...

CHILLI, Is your sled electric start...

chilli

New member

nope.....srx700...only hot grips

mulderdad

New member

pm'd ya chilli

bluewho

Active member

Do yourself s favor and get a new seal and gasket kit they will likely leak after pulling apart.Or if you are in a hurry for a first timer remove the servo moter 2 bolts and wires mark the cables with tape,remove the whole set and put them on the bench for cleaning.

Yps

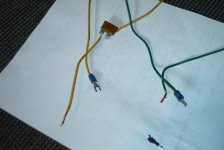

CHILLI, You’re going to have to put on your exhaust again and fire it up… this is step one; let it warm up abit and remove your servo cover & just screw out your idle (rpm) below 1000-900 rpm and watch the servo rotate, kill the engine and mark the spot with a black felt pen…(see photo) and mark the open and closed positions…now double check by readjusting the idle to 1700+/- 100 rpms and start and stop the engine and watch the servo and see if it opens to the mark you made…if so than there is no need to do this step anymore…I just use a pair of adjustable pliers and rotate the servo to the mark…Step two; remove the centre pipe, remove the exhaust manifold…(yes it is a pain)…now that the exhaust is off, you reach inside the exhaust port and feel the valve…it should be flush to the port-check all valves…now rotate the servo closed position and feel the valves close, if one is hung up than the(y) should be taken out and cleaned…if they all close o.k. then rotate your servo open again and reconfirm that they are opened…if not than adjust each valve at the servo…your are adjusting then to full open…keep an I eye on the servo mark as sometimes when you are adjusting them the servo starts to close abit…after adjusting, confirming that they are flush with the top of the port than your ready to close the exhaust up…Step three; replace the manifold, the centre pipe and the servo cover…FIRE HER UP…that sweet sound is back…your done…

Hope this helps out...good luck

Note: You do not have to adjust your valves every time you clean them…if your careful when removing them & they are not gummed up to the point where you have to take pliers to pull them out or if you have to clean the valve housing assembly…then you have to adjust everything up again…

http://www.totallyamaha.com/snowmobiles/aaTECH/YPVS/YPVS.htm

CHILLI, You’re going to have to put on your exhaust again and fire it up… this is step one; let it warm up abit and remove your servo cover & just screw out your idle (rpm) below 1000-900 rpm and watch the servo rotate, kill the engine and mark the spot with a black felt pen…(see photo) and mark the open and closed positions…now double check by readjusting the idle to 1700+/- 100 rpms and start and stop the engine and watch the servo and see if it opens to the mark you made…if so than there is no need to do this step anymore…I just use a pair of adjustable pliers and rotate the servo to the mark…Step two; remove the centre pipe, remove the exhaust manifold…(yes it is a pain)…now that the exhaust is off, you reach inside the exhaust port and feel the valve…it should be flush to the port-check all valves…now rotate the servo closed position and feel the valves close, if one is hung up than the(y) should be taken out and cleaned…if they all close o.k. then rotate your servo open again and reconfirm that they are opened…if not than adjust each valve at the servo…your are adjusting then to full open…keep an I eye on the servo mark as sometimes when you are adjusting them the servo starts to close abit…after adjusting, confirming that they are flush with the top of the port than your ready to close the exhaust up…Step three; replace the manifold, the centre pipe and the servo cover…FIRE HER UP…that sweet sound is back…your done…

Hope this helps out...good luck

Note: You do not have to adjust your valves every time you clean them…if your careful when removing them & they are not gummed up to the point where you have to take pliers to pull them out or if you have to clean the valve housing assembly…then you have to adjust everything up again…

http://www.totallyamaha.com/snowmobiles/aaTECH/YPVS/YPVS.htm

Last edited:

Pvs

Never had one that stuck or dirty...I run VES-2 and never had a issue

Never had one that stuck or dirty...I run VES-2 and never had a issue

bluewho

Active member

Thats a good explanation on setting and cleaning by the way.

chilli

New member

Thanks alot guys!

Skidooslayer687

Member

Kind of different question guys but relating to powervalves, i cleaned and adjusted my the other day, i found that the center cylinder cable to the valve to be adjusted properly had to be nearly bottomed out on the servo motor... that being said is this alright to run like this?? or should i get a new cable?? I did have a problem with this cable when i first bought my machine, the powervalve clogged, and the cable pulled threw the back of the valve, but to my knowlege the dealer repaired this and put a new cable on. Since then i switched oils and havnt had a problem with powervalves sticking since. Just wondering if this is alright to run with

Take the cable off and go to a dealer and match it up to the exact one you would need...my guess is that they just threw one on to get it going...most likely you have a longer one or (if they reused yours) your cable has stretched beyond adjustment...The rule is something has to give, either a valve eye tears or the cable stretches...good luck

Skidooslayer687

Member

Do need to remove it though, i have proper adjustment in the valves now with the cable as it is

cacsrx1

New member

If they are stretched U need to turn them out not in. If its adjusted correctly leave it alone.

vibeline

New member

very easy

I have always used the servo test port to adjust my exhaust valves on my 98 srx700. It is located either behind the air box or behind the left side of the dash panel.

The first time I used the servo port I also used the low idle method

(idle engine below 900 RPM) to verify that they were adjusted correctly.

The cable spool actuated to the same position using both methods.

you need a 12 volt battery, a 5amp fuse, 2 pieces of wire and 2 small fork type crimp on ends.

For the negative wire cut 1 of the legs off of the fork type connector.

Solder the fuse in line in the positive wire. (Tape it up when done)

Put the 2 leged fork on the positive wire (this goes to red wires in port)

Put the 1 leged fork on the negative wire (this goes to black wire in port)

Hook the bare ends of the wires to the battery.

(the fuse goes on the + side of battery)

Plug in positive first.

When the servo is full open I mark the cable spool position and disconnect the 12 volt power. If the spool moves while you are making an adjustment you can turn it back to the full open position by hand.

I have always used the servo test port to adjust my exhaust valves on my 98 srx700. It is located either behind the air box or behind the left side of the dash panel.

The first time I used the servo port I also used the low idle method

(idle engine below 900 RPM) to verify that they were adjusted correctly.

The cable spool actuated to the same position using both methods.

you need a 12 volt battery, a 5amp fuse, 2 pieces of wire and 2 small fork type crimp on ends.

For the negative wire cut 1 of the legs off of the fork type connector.

Solder the fuse in line in the positive wire. (Tape it up when done)

Put the 2 leged fork on the positive wire (this goes to red wires in port)

Put the 1 leged fork on the negative wire (this goes to black wire in port)

Hook the bare ends of the wires to the battery.

(the fuse goes on the + side of battery)

Plug in positive first.

When the servo is full open I mark the cable spool position and disconnect the 12 volt power. If the spool moves while you are making an adjustment you can turn it back to the full open position by hand.

Attachments

Last edited:

Viper-Rules!

New member

Power Valve cleaning!

I find the easiest way is to remove 3 screws in servo cover. Take cover off. Then I turn the servo a quarter turn by hand counter clockwise to loosen cables. Then I remove the valves from cylinder head, and undue the valve from the wire by letting the end of the slot slide thru.

I find the easiest way is to remove 3 screws in servo cover. Take cover off. Then I turn the servo a quarter turn by hand counter clockwise to loosen cables. Then I remove the valves from cylinder head, and undue the valve from the wire by letting the end of the slot slide thru.

change_up

New member

Can it harm the servo motor if you leave the power source hooked up so that the servo doesn't move back as you get the cables tighter? My valves are far from flush with the port yet and the servo keeps getting pulled back as I tighten the cables.

vibeline

New member

servo motor

If the 12 volt power supply is fused you should not damage the servo motor.

Once the servo pulls the valves to full open It normally will stay in that position without the 12V power being hooked up. When the spool is in the full open position mark it and if it moves during adjustment you can turn it back by hand. The servo motor will turn the spool to the same position every time.

If the 12 volt power supply is fused you should not damage the servo motor.

Once the servo pulls the valves to full open It normally will stay in that position without the 12V power being hooked up. When the spool is in the full open position mark it and if it moves during adjustment you can turn it back by hand. The servo motor will turn the spool to the same position every time.

Last edited:

You are either tightening too much, or you have a problem in the cable or valve somewhere. When adjusted properly there should not be enough tension on the wires to turn the servo motor.change_up said:Can it harm the servo motor if you leave the power source hooked up so that the servo doesn't move back as you get the cables tighter? My valves are far from flush with the port yet and the servo keeps getting pulled back as I tighten the cables.

change_up

New member

I must have a problem with the cables somewhere... because I can still reach in the exhaust port and push the valve up another 1/8 inch or so until it bottoms out... and it is not quite flush with the exhaust port (very fine line to go, but it's not quite there... maybe 1/32" or so) This happens on all three valves but the worst is on the Mag side valve. Any ideas?