saskattakman

New member

I am looking to adjust the powervalves on my srx and i know this question has been answered many times but what is the best way to set them....i have a broken cable and want to replace it and set the rest.....according to 2 yammy shop manuals hook up the battery power to servo motor and set clearance between the vavle and housing the other one says clearance between the end cover and housing....on this site it say to pull exhause pipes and feel for clearance ilde below 1000 to get the motor to open valves....can anybody add to this or tell me the best way to do this.....also between setting clearance or removing the pipes is there that much difference between the 2....i know when my sled was taken to the local yammy shop they never pull the pipes off.....also how much performance gain will i see with all 3 working and set right.....i can only pull 8100 right now

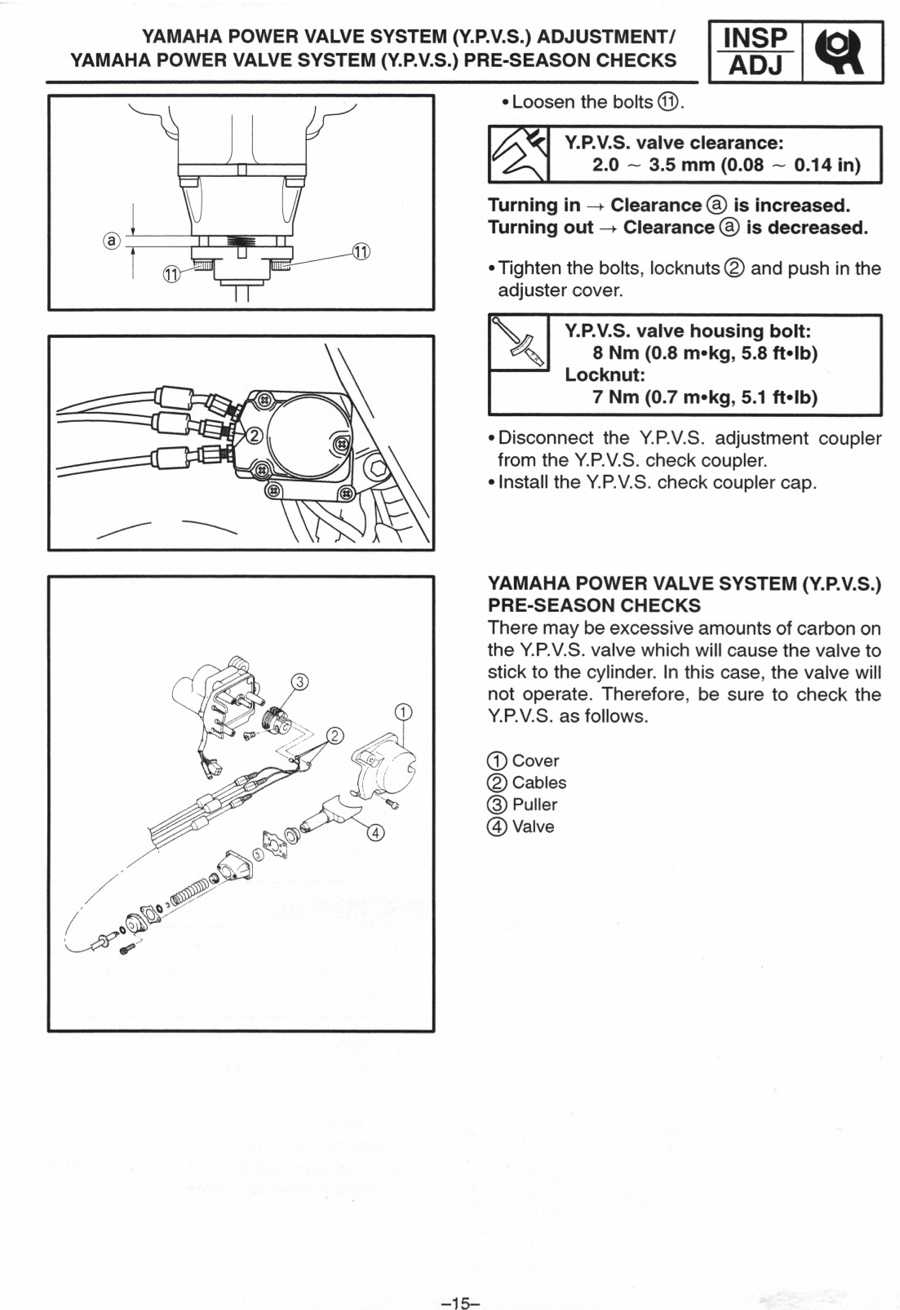

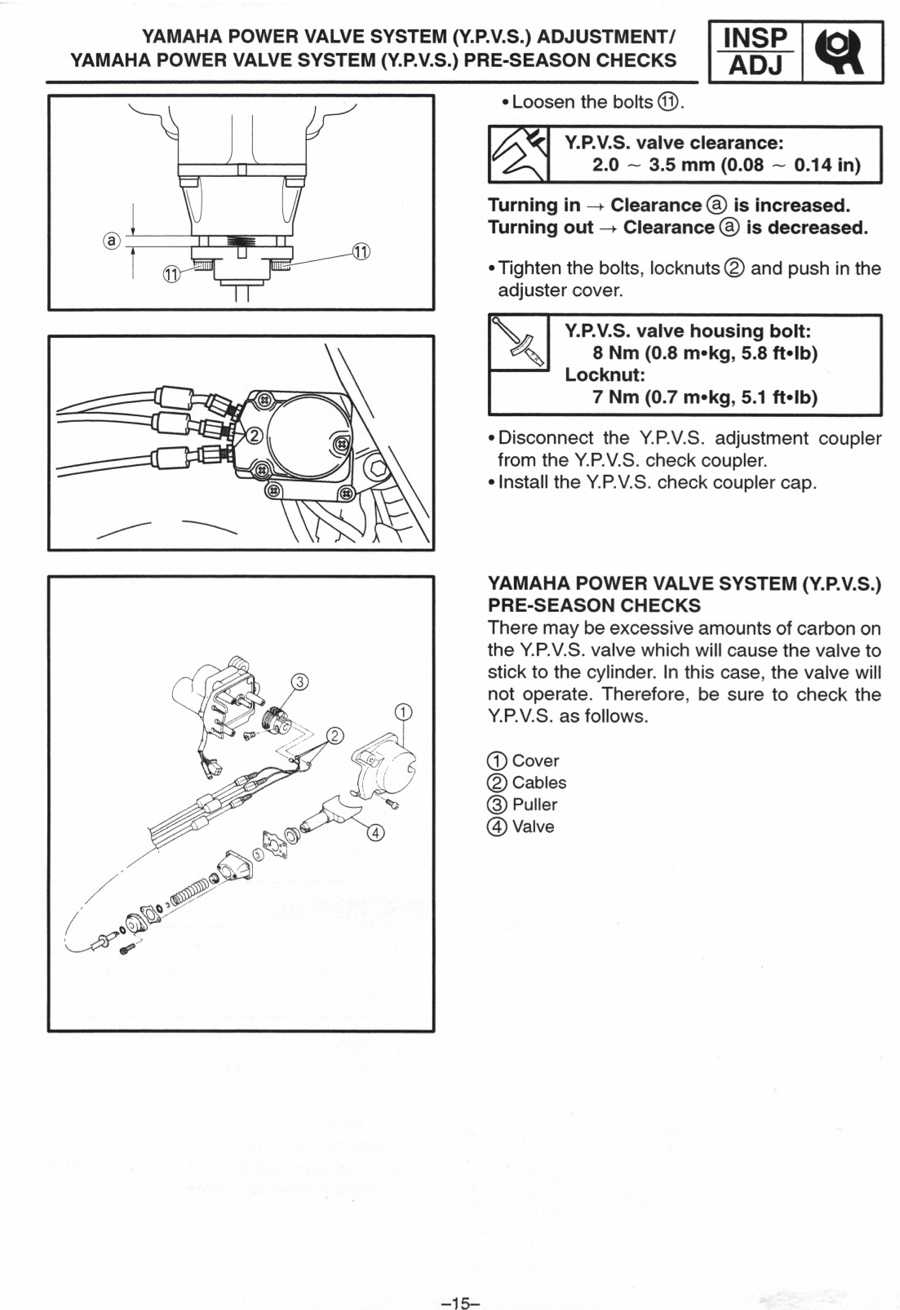

Well I have to disagree, the reason yamaha tells you to set the clearance at 2.5mm is so the cable isnt pulled taunt every time the valve opens, when you pull the pipes and adjust them with your finger ,they are bottomend out and thats why you pull the cables out thru the valve ends, theres no performance differance as the edge of the valve is what raises the roof of the exh.port and its way back inside when adjusted properly to the spec that yamaha gives you.

redsnake3

New member

its not mr.vipers way its the yamaha way. check a manual.

mwedig

New member

The Yamaha way is the suposly the best way.

I took off the exhaust and tried something recommended to be by a fellow yamaha friend. What I found out is you can set the valves much quicker if you tighten the cables until the servo motor hums/ and turn it back in one revolotion or a little more. The valves are still way out of the way (checked the exhaust port) and they are not too tight.

So if you have the valves clean you can stick them in and not mess with the 2.5mm clearance.

I took off the exhaust and tried something recommended to be by a fellow yamaha friend. What I found out is you can set the valves much quicker if you tighten the cables until the servo motor hums/ and turn it back in one revolotion or a little more. The valves are still way out of the way (checked the exhaust port) and they are not too tight.

So if you have the valves clean you can stick them in and not mess with the 2.5mm clearance.

here is how i set mine, drop my idle to around 700, (servo fully opens below 900)

scrib a line on servo mounting suface which will be there year after year. years 2000

and 01 machines middle cable slot is real close to being straight up so I scribe my line in the center of that slot on the aluminum behind the cable pully. loosen the cap screws holding the valve and slightly pull the cap untill you feel it stop and set the gap with two 7/64 drills which are .110 in dia. If i remember the spec was from .080-.140 which is in the 2.5mm range. I use the two drills kinda like feeler gages one each side to keep it square and then adjust the cables.Then just for a dbl check i screw one bolt in until it just touches the cap (with it still pulled out to the .110 drill)

then push the cap in and measure from the inside of the cap screw to the mating surface on the housing with a scale. may seem like alot of work but its really quit easy and acurate. I forgot to mention after shutting the machine down you need to line up the scribed line with the center slot, that is if you readjust the idle so the valve closes again if you shut the machine down at low idle the servo should stay where you want it.

scrib a line on servo mounting suface which will be there year after year. years 2000

and 01 machines middle cable slot is real close to being straight up so I scribe my line in the center of that slot on the aluminum behind the cable pully. loosen the cap screws holding the valve and slightly pull the cap untill you feel it stop and set the gap with two 7/64 drills which are .110 in dia. If i remember the spec was from .080-.140 which is in the 2.5mm range. I use the two drills kinda like feeler gages one each side to keep it square and then adjust the cables.Then just for a dbl check i screw one bolt in until it just touches the cap (with it still pulled out to the .110 drill)

then push the cap in and measure from the inside of the cap screw to the mating surface on the housing with a scale. may seem like alot of work but its really quit easy and acurate. I forgot to mention after shutting the machine down you need to line up the scribed line with the center slot, that is if you readjust the idle so the valve closes again if you shut the machine down at low idle the servo should stay where you want it.

saskattakman

New member

power vavles

man i am more confused them before

so mr. viper are you saying to set them the yamaha way or set them by pulling the pipes off.....i like the way of setting them the yammy way much quicker and easier to do.....any difference between the 2

man i am more confused them before

so mr. viper are you saying to set them the yamaha way or set them by pulling the pipes off.....i like the way of setting them the yammy way much quicker and easier to do.....any difference between the 2

that is the way yamaha does it I just dont use the connector from yammaha

to open the servo I drop the idle maybe ill send pic from the book if it would help

to open the servo I drop the idle maybe ill send pic from the book if it would help

I read the other post daman, I have done it by feel also i just prefer

to use the measurement way. dont have to remove pipes, if they are already off it is a good dble check, I guess its tomato, tamoto or something like that.

Try both see what is best for you

to use the measurement way. dont have to remove pipes, if they are already off it is a good dble check, I guess its tomato, tamoto or something like that.

Try both see what is best for you

yamaholic22

Active member

I do it so that the bottom of the valve is flush with the top of the exhaust port. I guess i dont really understand what mrviper was saying about over pulling the valves by adjusting this method, because you are basically setting the cables for the least amount of pull possible without having the valve obstruct the exhaust port when the servo is at its full open position. With yamaha's spec, for one there is variance with using a tolerance like that, you don't really know where it is at, and also they can be pulled open too far (pulling the valve ABOVE the top of the exhaust port) which over time will put more stress on the cable and top of the valve, increasing the chance that it will pull through. So for me, i lower the idle below 900 to get the valves to open on their own, mark the position of the servo (which should never change again), and pull the pipes and feel the exhaust port for when the valves are flush. If they are higher than flush, it is extra stress on the cables and valves and unecessary turbulence in the exhaust. If they are below flush, the aren't fully clearing the port and you will lose a little top end power. For me the only way is to pull the pipes and feel for the right adjustment. Hope that clears this up some, instead of dumping mud in the water.

I have pic put dont know how to send it?

daman

New member

host at photobucket.com then copy and past thr URL here..2muchhp said:I have pic put dont know how to send it?

The Yamaha method thats in the service manual takes about a 1/4 of the time and it is correct as to the valve placement in the cylinder when opened. It adjusts the valve perfectly and the exh. port opening roof is raised, thats where your power increase is from not the short end of the bevel being flush on the exh roof ,although the yamaha method will put the valve in perfect adjustment. I have been doing them this way since 1998, to each his own. I dont have cables pulled thru the ends, never been a problem for me doing it this way, with the other way you are pulling the cable back further then needed and it does tug the valve against the return spring more, this applies more pressure to the cable end inside the powervalve tip.

If you feel the need to waste a good hour of your time, take off the manifolds and pipes and all and reach up in there and do it, I like to spend 15 mins and have the job complete and be out riding, but thats just me. I follow the book as its twice as easy and it works for me.

make your own decision and do whatever way you feel like is the right way to you!

If you feel the need to waste a good hour of your time, take off the manifolds and pipes and all and reach up in there and do it, I like to spend 15 mins and have the job complete and be out riding, but thats just me. I follow the book as its twice as easy and it works for me.

make your own decision and do whatever way you feel like is the right way to you!

flying yami

New member

The yamaha way was the easiest and fastest way for me too.

2.5mm, use a allen wrench to lay between the housings, very simple to do.

saskattakman

New member

adjust power valves

so Mr. Viper you are saying to idle below 900 rpms to get the motor to open up mark the servo position in full open.....shut sled off....make sure servo is in full open according to the line..loosen screws on powervalve outer housing and adjust cables to 2.5mm then reinstall everything....is there any difference between setting them to 2.5mm from the valve to inner housing or is this the exact same thing just don't have to remove the vavle....

thanks guys for your input on this makes it much easier to set valves then removing the pipes all the time....

so Mr. Viper you are saying to idle below 900 rpms to get the motor to open up mark the servo position in full open.....shut sled off....make sure servo is in full open according to the line..loosen screws on powervalve outer housing and adjust cables to 2.5mm then reinstall everything....is there any difference between setting them to 2.5mm from the valve to inner housing or is this the exact same thing just don't have to remove the vavle....

thanks guys for your input on this makes it much easier to set valves then removing the pipes all the time....

the 2.5mm gap is between the powervalve housings, the part with 4 bolts you dont touch, you do everything as you listed below except you loosen the 2 bolts on end of block till they are only in by a couple threads, then wiggle the cable end/block, it will pop open and there will be a gap between the 2 housings, adjust this gap to 2.5 mm.

SRX7

New member

Here ya go

Skidooslayer687

Member

This method sounds much easier then pulling the pipes and manifolds each and everytime, takes quite a bit of time to rip the pipes and manifolds off and adjust each valve like that

SRX7

New member

Ya and snap a header bolt.