snow guy

New member

Can anyone give me ideas on how to support the running board area where the trailing arm connects to it? On one side of my Mtn. Viper it is bent from a hard hit at some point. Will the standard fishback style running board supports do the trick or is there some other way. Also how do I get the bend out of it now.

Vmax Al

New member

If you give Bender Racing a call they used to have a support that bolted under the board around the arm attach. I added a set after mine took a hit, wish I would have had them before. It will be a while until I see my sled but could snap you some pics if you like in a month or so.

MtnMax600

New member

Depends on how bad it is. I had a badly bent one last year from a tree. It had actually torn the metal of the tunnel around the mount for the trailing arm.

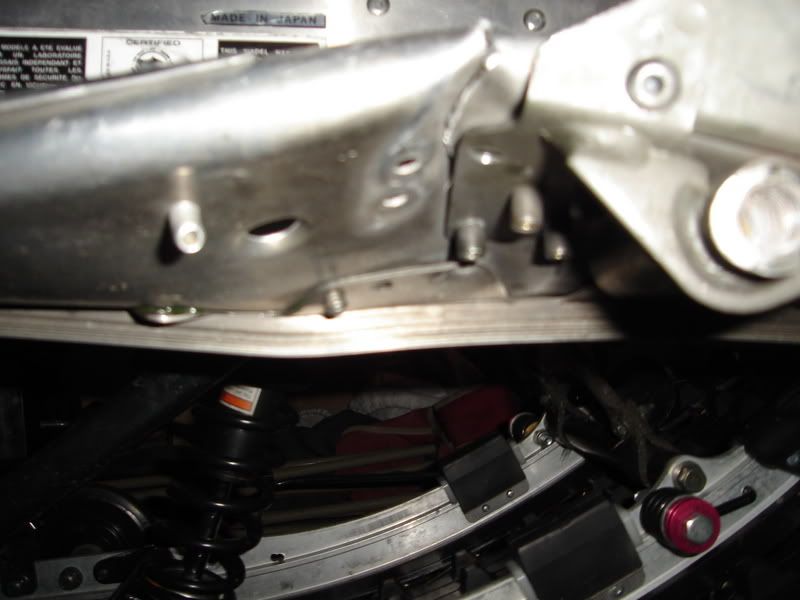

pics of how bad it was:

I had to drill out the trailing arm mount rivets, the foot well and basically everything around that section. I then hammered it and used C clamps to bend it all back to straight as I could. After it was straightened I got some aluminum sheet and riveted it on to support the torn section. Then I bolted the trailing arm mount back on. It was a real bitch of a job. It had bent the heat exchanger a little bit as well, which cracked it. I ran it for the rest of the season until the crack grew and I had to replace the heat exch., which I did this summer. I dont have any pics handy of the final fix, but it held up well and has felt solid since. Time will tell how it takes a shot on that side.

pics of how bad it was:

I had to drill out the trailing arm mount rivets, the foot well and basically everything around that section. I then hammered it and used C clamps to bend it all back to straight as I could. After it was straightened I got some aluminum sheet and riveted it on to support the torn section. Then I bolted the trailing arm mount back on. It was a real bitch of a job. It had bent the heat exchanger a little bit as well, which cracked it. I ran it for the rest of the season until the crack grew and I had to replace the heat exch., which I did this summer. I dont have any pics handy of the final fix, but it held up well and has felt solid since. Time will tell how it takes a shot on that side.

MtnMax600

New member

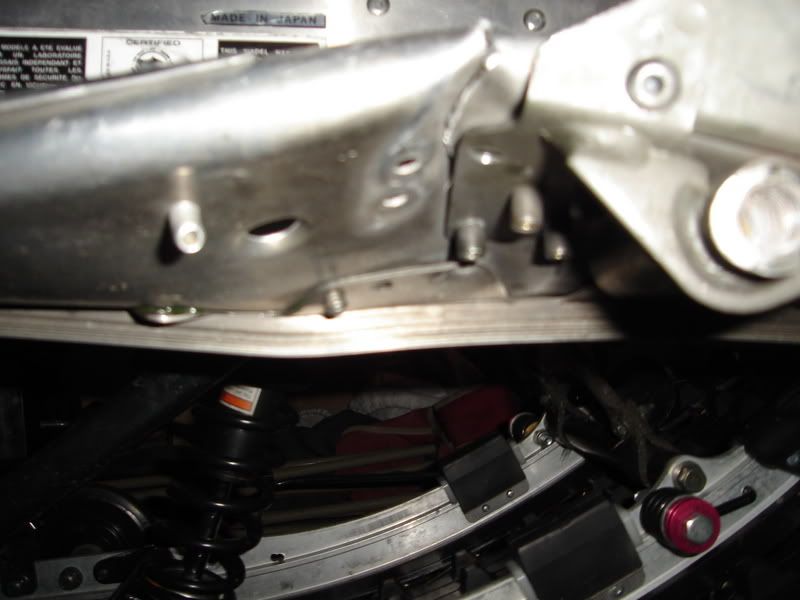

after removing parts and straightening:

Hopefully yours wasnt as bad. GOOD LUCK!!

Hopefully yours wasnt as bad. GOOD LUCK!!

Viper_Jim

New member

I had a similar injury to my Viper a few years back...pounded everything out with a hammer and C-clamps.....I also bought a set of those running boars supports....worked fine fr me....although I will be looking to get some extra supports fabricated in the future. good luck!

snow guy

New member

From the looks of yours mine is just a little tweak as you can see. My old MM had the same damage and I never did anything to fix it and was fine when I sold it. I'll see what Bender has and do some looking.

Attachments

MtnMax600

New member

Hell thats nothin. I ran mine for at least 800 miles looking like this(I did replace the arm) before the really bad damage happened. I would try to see if you can get the reinforcement parts and just beef it up. I didnt know anyone made parts to strenghthen this area.

Vmax Al

New member

Found my old thread from back in '04 where the part number was listed...

The part number is: TAB097. It retails for $44.95.

New phone number from their website, not sure how current it is as I have sent requests for info by email and got no reply...

BENDER RACING INC.

7804 Cole Road

Colden, New York 14033

(716) 941-5840

Fax (716) 941-6975

info@benderracing.com

HEATH LUX

OR

MIKE EBERT

The part number is: TAB097. It retails for $44.95.

New phone number from their website, not sure how current it is as I have sent requests for info by email and got no reply...

BENDER RACING INC.

7804 Cole Road

Colden, New York 14033

(716) 941-5840

Fax (716) 941-6975

info@benderracing.com

HEATH LUX

OR

MIKE EBERT

Call Bender

The Bender support mentioned above is the way to go. No doubt. That's just a little tweak......when you are done you'll never know it happend.

Madmatt

The Bender support mentioned above is the way to go. No doubt. That's just a little tweak......when you are done you'll never know it happend.

Madmatt

snow guy

New member

Vmax, can you describe what the supports look like, are they the fishbone oem style of something different. I know Bender is going through some changes and wonder when they will be up and running again.

Vmax Al

New member

It is flat and shaped somewhat like this and attaches under the footwell. Not sure on number of bolts but you get the idea. You replace some existing rivets to hold the template in place and then drill out the rest and use small bolts. They have flathead bolts and washers, allen head drive, and nyloc nuts, you could use a hex head bolt or even put them in "nut-side up" if you wanted extra traction in that area.

I got my running board as flat as possible with a hammer/clamp and then the support pulled it somewhat flatter yet, but it also conformed somewhat to the bend.

If you have access to material they would be easy enough to make up your own set.

I got my running board as flat as possible with a hammer/clamp and then the support pulled it somewhat flatter yet, but it also conformed somewhat to the bend.

If you have access to material they would be easy enough to make up your own set.

Attachments

PISTOL PETE

New member

I have 4 700 MM and after the first one took a hit I made supports out of diamond plate aluminum about 10" long. Bent them at 90 degrees and made a template for the angles then cut them out to fit just under the foot rest and up the side of the tunnel. Looks good and solved all my problems.

mm700sleder

New member

I wish i could help you out. I have a mini fabrication shop at home. If you had a tig welder you could repair that and make it twice as strong as stock. Good luck with the adventure.