blue missile

New member

just put slide on my nytro and like all mof my other sleds they will fit out throught the window. like somone said a little soap and alot of grunting and they will come out.

Swuff

New member

Good news first; Tied Brenda to the rafters in the garage dont know how I got the 2nd bolt at the rear out and will confirm I stripped the axle.

Good news I pulled the whole skid out; lets try and do this right.

Slides are off, stripped one screw. this was one of the easiest striped screws I have ever had the pleasure of doing.

Now just going to attack the axle and order a new one from the dealer. As well clean up some of the rust under there with some rust paint.

Be back with some more problems most likely.

Again, help is most appreciated.

Swuff

Good news I pulled the whole skid out; lets try and do this right.

Slides are off, stripped one screw. this was one of the easiest striped screws I have ever had the pleasure of doing.

Now just going to attack the axle and order a new one from the dealer. As well clean up some of the rust under there with some rust paint.

Be back with some more problems most likely.

Again, help is most appreciated.

Swuff

You will need to address the stripped bolt issue by either replacing the shaft or drilling and tapping for the next size up bolt.

The easiest way to get that other side bolt out is this:

1) Remove the first bolt all the way.

2) Locate a nut with the same threads.

3) Thread the nut all the way on to the bolt you just removed.

4) Re-install the bolt with the nut. run it down till the nut is close to the tunnel/bracket

5) using a pair of wrenches, tighten the but against the tunnel/bracket while holding the bolt head from turning.

6) Remove the bolt from the other side.

7) Remove your jam nut/bolt

Repeat on other shafts as required.

Repeat on other shafts as required.

The easiest way to get that other side bolt out is this:

1) Remove the first bolt all the way.

2) Locate a nut with the same threads.

3) Thread the nut all the way on to the bolt you just removed.

4) Re-install the bolt with the nut. run it down till the nut is close to the tunnel/bracket

5) using a pair of wrenches, tighten the but against the tunnel/bracket while holding the bolt head from turning.

6) Remove the bolt from the other side.

7) Remove your jam nut/bolt

Swuff

New member

Well the bad news go worse. THat wasnt the axle I stripped it was what they call "shaft 2 " (on the HLSM's page) the one that goes thru the pivot arm... went from a $ 30 fix to a $ 100 fix.

What is this shaft called so I know what to look for? Possibly any one know of a scap vmax that isnt going any where Id love to know. We have snow and I would like to get out as soon as possibe.

What is this shaft called so I know what to look for? Possibly any one know of a scap vmax that isnt going any where Id love to know. We have snow and I would like to get out as soon as possibe.

marty f

New member

listen up!!!

ok i have removed the slides with the skid in and out,when you take out the slides with the skid in first take the screw out then take a hammer and a large screw driver and put it in the hole where the screw was. (you have to roll the track so you can position the window for the right angle for the screw driver ).pound on the end of the screwdriver and as the slide moves back make sure to roll the track to keep a good angle,when the slide pertrudes out the track window take a wood screw and screw it thru the end of the slide about an inche in, then take a long pry bar and lock it on the screw as if your were going to pull a nail out now if you are lucky grab the end of the pry bar and sit on the ground facing the back of the sled and put both feet on the track and pull like helll and maybe just maybe it will slide back as you pull..if it does not slide back take a hammer to the pry bar and pound it with a hammer to get it out!!!

you can also put a wood screw in from the side of the slide a little over halfway back on the skid if there is enough slide to put one in and then you have somewhere to get leverage for a screw driver or even a 2x4 works good to use..

remember if you take the skid out when you put it back in take the bolt out on the end of the transfer rods or you will fight the skid for hours trying to get the back four holes to line up!!!!!!

good luck

ok i have removed the slides with the skid in and out,when you take out the slides with the skid in first take the screw out then take a hammer and a large screw driver and put it in the hole where the screw was. (you have to roll the track so you can position the window for the right angle for the screw driver ).pound on the end of the screwdriver and as the slide moves back make sure to roll the track to keep a good angle,when the slide pertrudes out the track window take a wood screw and screw it thru the end of the slide about an inche in, then take a long pry bar and lock it on the screw as if your were going to pull a nail out now if you are lucky grab the end of the pry bar and sit on the ground facing the back of the sled and put both feet on the track and pull like helll and maybe just maybe it will slide back as you pull..if it does not slide back take a hammer to the pry bar and pound it with a hammer to get it out!!!

you can also put a wood screw in from the side of the slide a little over halfway back on the skid if there is enough slide to put one in and then you have somewhere to get leverage for a screw driver or even a 2x4 works good to use..

remember if you take the skid out when you put it back in take the bolt out on the end of the transfer rods or you will fight the skid for hours trying to get the back four holes to line up!!!!!!

good luck

bluewho

Active member

Total recreation is 20 miniutes from you.Swuff said:Well the bad news go worse. THat wasnt the axle I stripped it was what they call "shaft 2 " (on the HLSM's page) the one that goes thru the pivot arm... went from a $ 30 fix to a $ 100 fix.

What is this shaft called so I know what to look for? Possibly any one know of a scap vmax that isnt going any where Id love to know. We have snow and I would like to get out as soon as possibe.

Swuff

New member

drill and tap bigger...... I dont have the resources for that, where would I go?

I was looking at how to take #50 (shaft 2) out when I got the skid out I pulled one wheel off by hand, just a little pull and it came right off. I put it back on and sort of poped back into place. I've only taken one wheel off so I dont know what to expect out of the other one. probably tighter than me on New Years Eve!

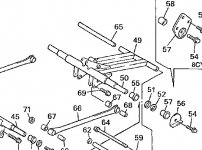

As well is # 65 that goes thru # 49 is slopy is that normal?

I was looking at how to take #50 (shaft 2) out when I got the skid out I pulled one wheel off by hand, just a little pull and it came right off. I put it back on and sort of poped back into place. I've only taken one wheel off so I dont know what to expect out of the other one. probably tighter than me on New Years Eve!

As well is # 65 that goes thru # 49 is slopy is that normal?

Ya, that's normal and sometimes you get lucky with the wheels  . Any little machine shop, fab place should be able to help you, maybe even the local mechanic. The post above yours mentions Total rec though......Maybe a phone call at least. The shaft should be the same over a bunch of pro-action years. That arm is generally referred to as the rear arm or scissor of the rear suspension.

. Any little machine shop, fab place should be able to help you, maybe even the local mechanic. The post above yours mentions Total rec though......Maybe a phone call at least. The shaft should be the same over a bunch of pro-action years. That arm is generally referred to as the rear arm or scissor of the rear suspension.

You'll also have to drill out the mount hole and any related washers and spacers if you go the drill and re-tap route. I should also include the possibility that you just cross threaded the first couple of threads and may infact be able to have the threads cleaned up with a tap of the correct size. Just throwing some thoughts out there....

. Any little machine shop, fab place should be able to help you, maybe even the local mechanic. The post above yours mentions Total rec though......Maybe a phone call at least. The shaft should be the same over a bunch of pro-action years. That arm is generally referred to as the rear arm or scissor of the rear suspension.

. Any little machine shop, fab place should be able to help you, maybe even the local mechanic. The post above yours mentions Total rec though......Maybe a phone call at least. The shaft should be the same over a bunch of pro-action years. That arm is generally referred to as the rear arm or scissor of the rear suspension.You'll also have to drill out the mount hole and any related washers and spacers if you go the drill and re-tap route. I should also include the possibility that you just cross threaded the first couple of threads and may infact be able to have the threads cleaned up with a tap of the correct size. Just throwing some thoughts out there....

Last edited:

Swuff

New member

Thanks Chief I wasnt to sure what was meant by the post above mine.. Bluewho thanks,

I'll get it back tomorrow, taking it over to a machine shop in Barrie $ 10.00 , Not too bad.

What does drill out the mount hole mean?

I'll get it back tomorrow, taking it over to a machine shop in Barrie $ 10.00 , Not too bad.

What does drill out the mount hole mean?

Swuff said:Thanks Chief I wasnt to sure what was meant by the post above mine.. Bluewho thanks,

I'll get it back tomorrow, taking it over to a machine shop in Barrie $ 10.00 , Not too bad.

What does drill out the mount hole mean?

The mount hole is the hole in the side of the tunnel ...where the bolt goes thru into the #50 axle part that was stripped. If you drill and tap to the next size thread, Your old bolt hole will not be big enough, Drill the mount hole and the washers that go with the bolt to a bigger size that fits your new bolt/thread combination.

Swuff said:What does drill out the mount hole mean?

The hole in the tunnel the bolt goes through may need to be a little bigger if you're going to a larger bolt. Just check with the new bolt if it will go through the hole.