RJH

New member

Your sleds……I didn’t answer right away as I was trying to think of something smart to say….but I can’t think of anything better than…… than they just look fantastic. Better than the real ones.

Can’t believe the amount of work you did….cool ala Artic Cat 4 pugs to. Good you have VM’s on them as well. If you haven’t already…take out the high speed air jets and re-jet the main. The AJ even a 0.8 won’t let the fuel atomize right.

I’ll do one sled section at a time. Ohhh… just one thing…my seat was lower, hard and had a grain surface.

Front End:

Yes….the 76’s had the front arm extended outside the aluminium body. This was how they all were.

Ours

A lot had to do with the modified skid..I’ll tell you later about. At the front….you could not get the weight to the right carbide. Here is a picture of the year before in mod stock…..we were not allowed saw up the chassis…just the engine (however ours was a stock GYT kit on pump fuel for most HP)

This is what steering with the inside ski looks like below….we still won every weekend in one class…but it was a wild ride.

Basically – they changed the 76’s so when you turned the ski the carbide was right underneath it. When you use a saddle – the carbide turns on an arc. We had the illusion of using the full saddle…but our carbide was basically right under the spindle. So….about 3” in from the 76 model.

Anyway….sitting on the sled…the right carbide was under the spindle – the left was stock.

This is how much bite we had…..

We spent a lot of time trying to keep the right leaf spring from folding under. One time we got a ½” solid titanium rod. We made a sleeve for the ski and a sleeve on the top of the saddle. We bent the Ti to a 90 and installed it. The ski would move up and down..but not fold under.

First heat – I bent the rod there was so much force.

So friggin stupid…..why didn’t we just make the spring solid. Take the dam leaf springs off…extend the spindle and super brace it….perfect – the tracks were always smooth ice back then…so stupid….

I wouldn’t change your front end…it looks nice.

No - I wasn't fat.

Can’t believe the amount of work you did….cool ala Artic Cat 4 pugs to. Good you have VM’s on them as well. If you haven’t already…take out the high speed air jets and re-jet the main. The AJ even a 0.8 won’t let the fuel atomize right.

I’ll do one sled section at a time. Ohhh… just one thing…my seat was lower, hard and had a grain surface.

Front End:

Yes….the 76’s had the front arm extended outside the aluminium body. This was how they all were.

Ours

A lot had to do with the modified skid..I’ll tell you later about. At the front….you could not get the weight to the right carbide. Here is a picture of the year before in mod stock…..we were not allowed saw up the chassis…just the engine (however ours was a stock GYT kit on pump fuel for most HP)

This is what steering with the inside ski looks like below….we still won every weekend in one class…but it was a wild ride.

Basically – they changed the 76’s so when you turned the ski the carbide was right underneath it. When you use a saddle – the carbide turns on an arc. We had the illusion of using the full saddle…but our carbide was basically right under the spindle. So….about 3” in from the 76 model.

Anyway….sitting on the sled…the right carbide was under the spindle – the left was stock.

This is how much bite we had…..

We spent a lot of time trying to keep the right leaf spring from folding under. One time we got a ½” solid titanium rod. We made a sleeve for the ski and a sleeve on the top of the saddle. We bent the Ti to a 90 and installed it. The ski would move up and down..but not fold under.

First heat – I bent the rod there was so much force.

So friggin stupid…..why didn’t we just make the spring solid. Take the dam leaf springs off…extend the spindle and super brace it….perfect – the tracks were always smooth ice back then…so stupid….

I wouldn’t change your front end…it looks nice.

No - I wasn't fat.

YAMAHABUNCH

New member

Front End:

Yes….the 76’s had the front arm extended outside the aluminium body. This was how they all were

Maybe in Canada but not in the U.S. Look at the Best of SnoPro book 73-78 at pages 143 Jerry Fiske and page 145 Ed Schubitzke. Just my 2 cents

Yes….the 76’s had the front arm extended outside the aluminium body. This was how they all were

Maybe in Canada but not in the U.S. Look at the Best of SnoPro book 73-78 at pages 143 Jerry Fiske and page 145 Ed Schubitzke. Just my 2 cents

tseaberg

New member

Hey Leon, good to see you on here!

Again Thanks alot for all your info RJH please keep it coming!!!!

As for the seat, I do not totally like the seat either but it will most likely stay that way for now. And as for the height. It is sort of an illusion as the foam is maybe 3" tall at most, but the flaps that hold it onto the tunnel extend fown about 1.5" so thats what makes the seat look so thick.

also on the ski supports, did you ever try anything like what we have on the snopro clone? That seems to be the setup every one running in the U.S. was using. thick aluminum on each side of the leaf.

And last question's for now. Were the bulkheads on your liquid gpx's and 76 snopros aluminum? I know leons liquid gpx is aluminum and was wondering if yours were too? also the hood's, were they just regular fibre glass or were they some sort of other composite material like Carbon fibre or a mixture of CF and fibre glass?

Thanks!!!!

Again Thanks alot for all your info RJH please keep it coming!!!!

As for the seat, I do not totally like the seat either but it will most likely stay that way for now. And as for the height. It is sort of an illusion as the foam is maybe 3" tall at most, but the flaps that hold it onto the tunnel extend fown about 1.5" so thats what makes the seat look so thick.

also on the ski supports, did you ever try anything like what we have on the snopro clone? That seems to be the setup every one running in the U.S. was using. thick aluminum on each side of the leaf.

And last question's for now. Were the bulkheads on your liquid gpx's and 76 snopros aluminum? I know leons liquid gpx is aluminum and was wondering if yours were too? also the hood's, were they just regular fibre glass or were they some sort of other composite material like Carbon fibre or a mixture of CF and fibre glass?

Thanks!!!!

RJH

New member

YAMAHABUNCH said:Front End:

Maybe in Canada but not in the U.S. Look at the Best of SnoPro book 73-78 at pages 143 Jerry Fiske and page 145 Ed Schubitzke. Just my 2 cents

Hey..yamahbunch

Thanks for the reply…if you have the book you must be an enthusiast. It was pretty interesting back then…however I guess it was normal at the time. Speeds on ½ mile ice ovals were over 100 mph..with 440.

All the 76 factory sleds 10 or less looked like the production models – wide….with covers over the extensions. I was there… don’t have the book. Could be two possible things.

1: It was a misprint

2: Well….. you can read the following if you have time.

You see…..just because it was a factory sled…..didn’t mean you could just go win…as many had fast factory sleds. There were like 5 or more heats…just to make the final. .... I would say – out of the box…the sled would not make a final.

This is probably why they did it…if it wasn’t a misprint….my sponsorship was part from Yamaha Canada East to race in Canada. Yamaha West was the main branch at the time…..and controlled who did what.

I only got to race against the very best at Peterborough, Quebec and some came to a race mid season. My mechanic and I were smart…we understood how things work…if you read my other post…you will see how we got the front end to work.

The 1st race was Peterborough….Adema (he was just hired by Yamaha) had just been killed the week before, but US team engineers were there at Peterborough I’m sure.

I won every heat and the final in 340 by over ¼ lap both days.

The 440 engagement was too high and I couldn’t get off well. The harmonic balance was shaking the Cat clutch to pieces in the 440. The best we could get was 2nd and 3rds. We could fix this..but not there.

In the 440 final…I was working my way to the front- heading for 2nd with 3 laps to go. A famous guy’s throttle stuck sending me into the wall and him thru the board’s one lap later.

They did give me the 1st ever Jim Adema memorial award for the effort.

Still here reading

…..anyways – my sleds were on rails – I had the 75 frame…did the engineers go back and tell Ed …that was the hot setup? No..I think it was a misprint.

…..anyways – my sleds were on rails – I had the 75 frame…did the engineers go back and tell Ed …that was the hot setup? No..I think it was a misprint.And……even thou I had run up front with the best in the world……I could not get to Eagle River the next weekend…would I have won????

In closing:

My two 76 sleds have been found...but the two 75's (which I raced in 76 are gone). The 76's I have seen - have the 75 engine in them.

If you are nice to me - I'll tell you how to make your GPX go real fast

Attachments

RJH

New member

tseaberg said:also on the ski supports, did you ever try anything like what we have on the snopro clone?

And last question's for now. Were the bulkheads on your liquid gpx's and 76 snopros aluminum? I know leons liquid gpx is aluminum and was wondering if yours were too? also the hood's, were they just regular fibre glass or were they some sort of other composite material like Carbon fibre or a mixture of CF and fibre glass?

Thanks!!!!

Ski supports – you have no idea….

we worked on the sleds almost 12 hours a day everyday except Friday.

we worked on the sleds almost 12 hours a day everyday except Friday.In the end we had two supports, on each ski, of what you show….. but just on one side – we only turned left.

We made them from steel…but they had a ½” plate on the side that faces the spring. For more support.

Weight… I could almost pick it up by the handlebars.

Hood – I’m not sure….paper thin…I don’t remember weaving on the inside.....

Pipes – I could squash them in my hand if I tried

Frame – (you asked) all 7075 T4 aluminium = 100% very light

Skid – same

Handlebars and steering post - same

Pistons – light

Ignition – TZ

Track – exclusive to us – coated Titanium called arboly –

The only other team to have that (at the time) was Polaris factory. It was made by the guy that owned Manta. I think maybe 15 #’s +/-

The jackshaft was steel…..because – of rotational mass. You see..it takes less effort to spin a 1” steel shaft than it does a 1 ¼” aluminium shaft. What we did is machine it smaller between brake and clutch bearing.

We further machined every rotating part down to a size where it just worked.

dynofun

New member

- Joined

- Nov 14, 2005

- Messages

- 355

Ed's winning sled was not a widened frame. I wonder if he got onto what you did... I do know that they said even a stock 76 SRX motor was stronger than the best liquid GPX and the Sno Pro 76's were quite modded. Good stuff RJH.

Gorkon

New member

Geez! The odd time I entered my stock GPX 338 in the other classes and and saw firsthand that the factory sleds were color-me-gone as soon as the checkered flag dropped. I couldn't believe the difference! Now I know why, I had no idea then. G.

YAMAHABUNCH

New member

(All the 76 factory sleds 10 or less looked like the production models – wide….with covers over the extensions. I was there… don’t have the book. Could be two possible things.

1: It was a misprint

2: Well….. you can read the following if you have time.)

Bob

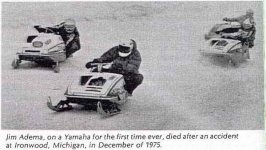

I attached a picture of Jim Adema taken right before his Accident at Ironwood MI. You can see that his sled is not widened and the production SRX in second is not widened either, nor, is Dick Trickle's SnoPro in third. All I'm saying is that the 76 SnoPro's in the U.S. did not come Widened like the 77-80 SRX's

Also Len Champoux's 76 SRX SnoPro was widend by his Father Gerald at Eagle River the night before Qualifying heats for the World Championship

Maybe Bob Works was ahead of the Game for the Canadian drivers.

1: It was a misprint

2: Well….. you can read the following if you have time.)

Bob

I attached a picture of Jim Adema taken right before his Accident at Ironwood MI. You can see that his sled is not widened and the production SRX in second is not widened either, nor, is Dick Trickle's SnoPro in third. All I'm saying is that the 76 SnoPro's in the U.S. did not come Widened like the 77-80 SRX's

Also Len Champoux's 76 SRX SnoPro was widend by his Father Gerald at Eagle River the night before Qualifying heats for the World Championship

Maybe Bob Works was ahead of the Game for the Canadian drivers.

Attachments

Last edited:

RJH

New member

Dynofun

In practice, I went out …..side by each with Larry Ohmans….and our 440’s had identical speed. As I mentioned in a previous post, mine was not running its best. We got the 75 in like June...so we favoured that model and spent a lot of time on it.

A lot of time was spent modding engines like the Kohler – but …personally…I can’t see how one could get any more reasonable HP out of a Yamaha factory engine. We won’t get into that here. We used the 75 as we had the clutching dialled – the 76 had more rpm.

Gokon… Yamaha suff has more potential than we will ever realize.

Yamahbunch

Hey – you are the Koch guys…you do a good job. Nice to talk to you.

I’M WRONG….that 76 in the background jogged my memory. I went on a no engine of any kind sabbatical from the mid 80’s to 99….(wanted to get the kid thru University first) I guess some memory was flushed.

When I saw that picture – of the stock 76..it hit me. And…that is why when I look at my 75 sled…it is widened..I guess someone did that after…… So where are my 76 sleds…they have not been found yet…man this really messes up my day….

Funny how Len would widen it and we narrowed it. You can see that stock frame 76 is inside ski steering.

What I have been thinking,,,,maybe…we quit in 77 but someone gave me a 77 to race and one of it problems – beside so wide – it would not steer….one of the many things we fixed was taking 4 degrees of caster out……wait…..if we did that in 76 and widened it….hmmmm did Len do that????

Too much thinking….. anyways…You are right..I am wrong.

In practice, I went out …..side by each with Larry Ohmans….and our 440’s had identical speed. As I mentioned in a previous post, mine was not running its best. We got the 75 in like June...so we favoured that model and spent a lot of time on it.

A lot of time was spent modding engines like the Kohler – but …personally…I can’t see how one could get any more reasonable HP out of a Yamaha factory engine. We won’t get into that here. We used the 75 as we had the clutching dialled – the 76 had more rpm.

Gokon… Yamaha suff has more potential than we will ever realize.

Yamahbunch

Hey – you are the Koch guys…you do a good job. Nice to talk to you.

I’M WRONG….that 76 in the background jogged my memory. I went on a no engine of any kind sabbatical from the mid 80’s to 99….(wanted to get the kid thru University first) I guess some memory was flushed.

When I saw that picture – of the stock 76..it hit me. And…that is why when I look at my 75 sled…it is widened..I guess someone did that after…… So where are my 76 sleds…they have not been found yet…man this really messes up my day….

Funny how Len would widen it and we narrowed it. You can see that stock frame 76 is inside ski steering.

What I have been thinking,,,,maybe…we quit in 77 but someone gave me a 77 to race and one of it problems – beside so wide – it would not steer….one of the many things we fixed was taking 4 degrees of caster out……wait…..if we did that in 76 and widened it….hmmmm did Len do that????

Too much thinking….. anyways…You are right..I am wrong.

Last edited:

tseaberg

New member

Well, now that we got this sort of figured out I will have to say that I have never seen a picture of any of the black hooded "canadian" 76 snopro's that have the un-widened front end. But to me it looks like the reason for widening the 76 snopro's was to stay at the same total ski center width but remover the weak ski spreaders. Also eventually by the pictures Dick Trickles 76 snopro got widened at some point. And all the widened ones have the ski spreaders removed so that is my basis on they wanted to get rid of that weak link.

So now I do have a question, Did all of the 76 snopro's have the brake rotors drilled to lighten them or was that just a personal preference for each team?

Also did you guys stick with the aluminum chaincase cover or put on a composite one like some of the U.S. 75's?

So now I do have a question, Did all of the 76 snopro's have the brake rotors drilled to lighten them or was that just a personal preference for each team?

Also did you guys stick with the aluminum chaincase cover or put on a composite one like some of the U.S. 75's?

RJH

New member

tseaberg said:And all the widened ones have the ski spreaders removed so that is my basis on they wanted to get rid of that weak link.

So now I do have a question, Did all of the 76 snopro's have the brake rotors drilled to lighten them or was that just a personal preference for each team?

Also did you guys stick with the aluminum chaincase cover or put on a composite one like some of the U.S. 75's?

You guys certainly have some detail...guess we just didn't care then.

I’m afraid to answer.

Using a ski spreader makes the carbide turn in an arc. Not good. We didn’t have that problem as our 6” of carbide was moved in towards the sled. We only left the spreaders on for an illusion.

Just to confuse things.....my other sponsor wanted us to run a 250 so I could run 3 classes - they counted points in 3.

He managed to get me Bud Lees 75 Kohlor factory sled. After one ride - yikes...it would not turn.....we lifted the jack shaft up over top of the chassis - and moved the engine 6" to the right....ever look at the new Doo race sled set up..that's what it looked like.

It was on a rail...but we spent too much money on the ignition and engine...he parked it...just as it was getting fast.

I guess the thought of the day and today…go wide young man – not for me. If you get a chance – look at Benders factory mod Polaris – his ski’s were tucked in towards (in 0

Bob Work did the stuff like machining the crank to fit the Cat clutch….(I think) so he may have done our rotors. They were grooves not holes. We continued on by machining the jack shaft and every part that turned. I had a friend who supplied Titanium washers nuts and bolts to us.

Our biggest advantage was the Titanium (Arboly) track.

We had aluminium chain case covers. I never saw any other.

I wasn't in that loop...long story..can't tell...was bad...thats why I didn't make Eagle River

I can’t remember if Dick T. was at Peterborough in 76. If he was..he didn’t make the final. I did see him in 75 I think – but I was in mod stock then.

I’d like to tell you about our trick skid later..I will.

Last edited:

YAMAHABUNCH

New member

tseaberg said:Hey Leon, good to see you on here!

Again Thanks alot for all your info RJH please keep it coming!!!!

As for the seat, I do not totally like the seat either but it will most likely stay that way for now. And as for the height. It is sort of an illusion as the foam is maybe 3" tall at most, but the flaps that hold it onto the tunnel extend fown about 1.5" so thats what makes the seat look so thick.

also on the ski supports, did you ever try anything like what we have on the snopro clone? That seems to be the setup every one running in the U.S. was using. thick aluminum on each side of the leaf.

And last question's for now. Were the bulkheads on your liquid gpx's and 76 snopros aluminum? I know leons liquid gpx is aluminum and was wondering if yours were too? also the hood's, were they just regular fibre glass or were they some sort of other composite material like Carbon fibre or a mixture of CF and fibre glass?

Thanks!!!!

From What I know about the front stub material, it was steel also the Tank on your clone is what most used for 76 the 75 style that went all the way down to the running board would not allow the driver to get his left foot forward enough. But for Eagle River they put the larger 75 style tank on because it had a larger fuel capacity for the longer 15 lap race !

Good talking with you too Bob I have heard a lot about you!

Hey heres a link to our new website I think you guy's will enjoy it

It does have a few mistakes that are being corrected

http://www.vintageyamahasnowmobiles.com/

Thanks

Leon

tseaberg

New member

wow, Thanks again for all the info its great!!!

That story about the kohler is a good one!!! and you bet I know what a xp skidoo looks like. Just spent the last 9 hours fitting a 600 mod airbox and intake to my 800R summit. that was a huge job!!!!! not as easy as it looks and I was told it would be impossible, so of coarse it was a challenge then

that was a huge job!!!!! not as easy as it looks and I was told it would be impossible, so of coarse it was a challenge then

so Leon, the tank on the clone is close to what they used in 76? I thought they were more flat and square like the snopro of champioux's? Tom just had this one made up to look something like a tank that might have been used. It shure looks good!!!

so on the rotor's. did they look like the one in this picture?

also look at the picture of the rear suspension adjust in the second picture. I have never seen another with it positioned so far forward? Has anybody else?

Also this is on a 75 liquid gpx.

thanks!!!!

That story about the kohler is a good one!!! and you bet I know what a xp skidoo looks like. Just spent the last 9 hours fitting a 600 mod airbox and intake to my 800R summit.

that was a huge job!!!!! not as easy as it looks and I was told it would be impossible, so of coarse it was a challenge then

that was a huge job!!!!! not as easy as it looks and I was told it would be impossible, so of coarse it was a challenge then

so Leon, the tank on the clone is close to what they used in 76? I thought they were more flat and square like the snopro of champioux's? Tom just had this one made up to look something like a tank that might have been used. It shure looks good!!!

so on the rotor's. did they look like the one in this picture?

also look at the picture of the rear suspension adjust in the second picture. I have never seen another with it positioned so far forward? Has anybody else?

Also this is on a 75 liquid gpx.

thanks!!!!

Attachments

RJH

New member

It takes time to do a good job….I guess if the jetting was good before..you will have to re-jet…assume the mod box has better flow. The quest for better..does it ever end.

It’s hard to tell on sleds with so many variables…but when my son ran a 125 shifter kart he could hear the resonance in the special box we ran. The two air intake tubes were adjustable ….he said it wound up like a turbine sound if it was right. Shift RPM was about 14,0000.

Yes..the gas tanks was lower on the 75 – bigger on the 76.

That is what my rotor looked like..in the trick reversed picture. Same stamped look. Our jackshaft was turned down a lot.

It’s strange, there are no rivet holes in the original location where the plate should have been. Ours just had a metal bar - with an adjustment. It’s almost like he changed chassis to a steel front end.

I don’t think he moved the skid – I think he just lengthened the front arms. I think he was after more leverage, depending on the skid mount..….we did it another way. A third way would be to raise the point to which it connects to the skid.

Ours was so simple….Jacques sells a hydraulic skid today what ours did on its own. Getting too, long here..so next time.

If we had a stayed interested longer – we would have incorporated the following somehow.

We built a parallelogram suspension for our flat track bike with twin carb single cylinder Kawasaki. It had a reed valve carb and a rotary valve carb 36 mm …I broke a lot of bones on that project so it went aside. The front wheel would not come up – awesome starts.

Later…I built a sled with external shocks and springs…the shocks were mounted on the running boards behind my feet…hmmm. Did Polaris see that?

No pictures..just didn’t care at the time.

It’s hard to tell on sleds with so many variables…but when my son ran a 125 shifter kart he could hear the resonance in the special box we ran. The two air intake tubes were adjustable ….he said it wound up like a turbine sound if it was right. Shift RPM was about 14,0000.

Yes..the gas tanks was lower on the 75 – bigger on the 76.

That is what my rotor looked like..in the trick reversed picture. Same stamped look. Our jackshaft was turned down a lot.

It’s strange, there are no rivet holes in the original location where the plate should have been. Ours just had a metal bar - with an adjustment. It’s almost like he changed chassis to a steel front end.

I don’t think he moved the skid – I think he just lengthened the front arms. I think he was after more leverage, depending on the skid mount..….we did it another way. A third way would be to raise the point to which it connects to the skid.

Ours was so simple….Jacques sells a hydraulic skid today what ours did on its own. Getting too, long here..so next time.

If we had a stayed interested longer – we would have incorporated the following somehow.

We built a parallelogram suspension for our flat track bike with twin carb single cylinder Kawasaki. It had a reed valve carb and a rotary valve carb 36 mm …I broke a lot of bones on that project so it went aside. The front wheel would not come up – awesome starts.

Later…I built a sled with external shocks and springs…the shocks were mounted on the running boards behind my feet…hmmm. Did Polaris see that?

No pictures..just didn’t care at the time.

snopro

New member

RJH

Jacques' skid is electronic, not hydraulic. I have his kit on my 77 skid.

Jacques' skid is electronic, not hydraulic. I have his kit on my 77 skid.