vintage srx

Member

Has anyone used a sled pro clutch alignment tool.The one i purchased the top pin hits the frame above the clutch should i just remove that one.

Concept Carbon

New member

isnt it supposed to hit the frame and hold the primary to line it up

1badz

New member

- Joined

- Nov 19, 2005

- Messages

- 179

I don't have the Yamaha one, but I do use the Ski-doo DSA one. What do you think the chances are that, if you have the correct one, you have to start tearing it apart to get it to work?? Last resort, google the company and call them. You're probably doing something wrong!

sgauthier

Member

are you saying that one of the offset pins is touching the frame?

do not take this the wrong way, not sure if you know how to use it . you must remove the 2ndary slid the round bushing end over the shaft where the 2ndary was and then you lower the tool over the primary clutch until it drops all the way down inside. if it does not you need to loosen the mounting bolts, move motor until it drops and then you align the offset pins with the back of the primary clutch before you tighten everything up. if it is hitting the frame then you are not doing something correctly or it's the wrong one.

the yamaha one should be blue in colour but maybe yours isn't, at least the ones that Royal Distributing sells are colour coded to the brand they are to be used on.

do not take this the wrong way, not sure if you know how to use it . you must remove the 2ndary slid the round bushing end over the shaft where the 2ndary was and then you lower the tool over the primary clutch until it drops all the way down inside. if it does not you need to loosen the mounting bolts, move motor until it drops and then you align the offset pins with the back of the primary clutch before you tighten everything up. if it is hitting the frame then you are not doing something correctly or it's the wrong one.

the yamaha one should be blue in colour but maybe yours isn't, at least the ones that Royal Distributing sells are colour coded to the brand they are to be used on.

sgauthier said:are you saying that one of the offset pins is touching the frame?

do not take this the wrong way, not sure if you know how to use it . you must remove the 2ndary slid the round bushing end over the shaft where the 2ndary was and then you lower the tool over the primary clutch until it drops all the way down inside. if it does not you need to loosen the mounting bolts, move motor until it drops and then you align the offset pins with the back of the primary clutch before you tighten everything up. if it is hitting the frame then you are not doing something correctly or it's the wrong one.

the yamaha one should be blue in colour but maybe yours isn't, at least the ones that Royal Distributing sells are colour coded to the brand they are to be used on.

I have this tool for my Yamahas[SXs + SRX].

When I first used the tool to check + align the clutchs, I had to move one of our SX engines over slightly to allow the tool to drop down over the primary.

vintage srx

Member

Yes i have the blue one i did remove the secondary and slid it over the shaft and let it drop over the primary as per instructions it came with.Unless i need to add shims behind were the secondary was.Yes it is the center offset pin.

Last edited:

ottawaair

New member

are you setting center to center or offset, there is 2 different tools. one sets the c-c, the other is for the 15mm offset on the back side of sheaves.

vintage srx

Member

I will take some pict's tomorrow.

sgauthier

Member

ottawaair, this tool does both the centre to centre and the offset, also holds the engine in place while you tightened it down. it sounds like he is having problems lowering the tool into the primary, i'm assuming the middle offset indicator is hitting the frame extension.

Vintage. are you sure the indicators are on correctly? the one closests to the front of the machine i think should be the shortest one, and the longest one should be at the back of the tool. sorry, i don't have the tool with me at work today to double check that to make sure i don't have that backwards. Maybe someone here will reply who has the tool in hand to double check that. maybe the indciators or pins are in the wrong order. when i bought mine it was already assembled so that could happen. if the longer one is in the middle then it might get hung up on the frame extension. i just did my 98 last night and it is really close but does clear it. just something to look at.

we will know more when you post the pics.

Vintage. are you sure the indicators are on correctly? the one closests to the front of the machine i think should be the shortest one, and the longest one should be at the back of the tool. sorry, i don't have the tool with me at work today to double check that to make sure i don't have that backwards. Maybe someone here will reply who has the tool in hand to double check that. maybe the indciators or pins are in the wrong order. when i bought mine it was already assembled so that could happen. if the longer one is in the middle then it might get hung up on the frame extension. i just did my 98 last night and it is really close but does clear it. just something to look at.

we will know more when you post the pics.

The actual pins on the Sled Pro allignment tools are exactly the same length, but they use spacers under the front and middle pins [the most forward spacer is thicker then the middle one] The reason the pins have spacers is to allow for an initial slight engine misallignment to allow for engine movement on the rubber engine mounts under load. The theory being, that the engine + clutches under torque will now be in perfect allignment.

If the engine is run with solid engine mounts the spacers should be removed for allignment.

Our SRXs [as we all know] have a torque stop that is there to prevent engine and clutch misallignment under torque...kind of like running solid motor mounts.

If the engine is run with solid engine mounts the spacers should be removed for allignment.

Our SRXs [as we all know] have a torque stop that is there to prevent engine and clutch misallignment under torque...kind of like running solid motor mounts.

ExpertXViper

New member

The 3 pins arent made/long enough to hit the subframe, unless they changed the design from what I have. The pins are made to line up/sit flush with the inner part/fixed sleave of the primary clutch, this is where you get your alignment. This also helps you keep everything aligned as you torque down the engine.

BTW I have one Sled Pro FS for $125+shipping......pics are in the classfieds

BTW I have one Sled Pro FS for $125+shipping......pics are in the classfieds

staggs65

Moderator

pm'ed youExpertXViper said:BTW I have one Sled Pro FS for $125+shipping......pics are in the classfieds

sgauthier

Member

^^^what sideshow said. ^^^

sorry i didn't have the tool in front of me but i knew they were offset for the torque, just forgot that it used washers/spacers underneath the pins

sorry i didn't have the tool in front of me but i knew they were offset for the torque, just forgot that it used washers/spacers underneath the pins

Last edited:

jamie

Member

All I do is drop the alignment tool on the primary closest to the movable sheave then slide it over til the tool hits the secondary bearing mounted in the bulkhead.

Bushman

New member

jamie said:All I do is drop the alignment tool on the primary closest to the movable sheave then slide it over til the tool hits the secondary bearing mounted in the bulkhead.

BINGO!

BINGO!vintage srx

Member

staggs65

Moderator

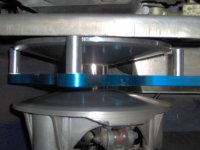

bringing this thread back since the one i bought is doing the same thing. what did you do? i'm thinking of notching the flange there a little. here some pics also. the first shows the tool isn't against the bearing yet. and in the second the pin hits the frame flange. funny we're the only ones with this problem.

bluemonster1

LIFE MEMBER ONLY ONCE!!!

I notched out the frame on mine for my clutch tool to drop down properly.

1badz

New member

- Joined

- Nov 19, 2005

- Messages

- 179

Here's the phone number for the tech dept. at Sled Pro

1-905-898-8003

Makes seen to go direct to the source, doesn't it??

1-905-898-8003

Makes seen to go direct to the source, doesn't it??

bluemonster1

LIFE MEMBER ONLY ONCE!!!

need someone to check their sled pro tool please.The very front pin has a thick washer,middle has a thinner washer and inside pin has no washer..is this correct?When I always do my alignment.the center pin never lines up flush with back of primary..the front and rear pins are the ones I make sure are flush..so the center oin is really useless..it is always sitting further ahead and not lined flush with back of primary.

Looks like the pin height with washer in front is 36mm,center with washer is 35mm and pin on the inside is 34mm.

Looks like the pin height with washer in front is 36mm,center with washer is 35mm and pin on the inside is 34mm.