Gorkon

New member

I am restoring a 70 SS 338 and plan on having the thermal barrier coatings done by Swain technologies on the piston tops and the poly graphite coating on the skirts. I have read on another site that it is not recommended to do the thermal barrier coating on top of the pistons, especially for free air engines!?

It was suggested that the F/A guys were experiencing problems because of this coating. I inquired as to exactly what problems and the reasons why and was never answered. Does anyone have any firsthand knowledge with this that can tell me what the concerns are?

I would think that it would a be blessing for free air engines and thought it was exactly what my old GPX 338 needed. When it was tuned to the edge when I was racing it had an insatiable appetite for pistons!

My thoughts are that it may simply take a little longer to get the engine properly warmed, as in, to get the piston warmed up and expanded the correct amount before any WOT. Other than that I can see no downside. Anybody? Thanks. G.

It was suggested that the F/A guys were experiencing problems because of this coating. I inquired as to exactly what problems and the reasons why and was never answered. Does anyone have any firsthand knowledge with this that can tell me what the concerns are?

I would think that it would a be blessing for free air engines and thought it was exactly what my old GPX 338 needed. When it was tuned to the edge when I was racing it had an insatiable appetite for pistons!

My thoughts are that it may simply take a little longer to get the engine properly warmed, as in, to get the piston warmed up and expanded the correct amount before any WOT. Other than that I can see no downside. Anybody? Thanks. G.

montynormand

Member

I have done the domes and head with their Thermal Barrior on a mod GP292 when I was fighting combustion chamber temps. Seemed to help, but that was a 1 year project and I really cant say it solved all my problems.

For the price, I think it was worth a shot

For the price, I think it was worth a shot

Gorkon

New member

Thanks Monty, I too believe it is worth it. Like I said, when I asked for specifics I didn't any response, no one was willing to step to the plate and stand behind their statements. I'll keep watching here though for any other input as I have thought I would definitely do it to any free air motors I get in the future.

Best of luck selling your SR, hope you get what you're looking for out of it. I saw the ad and you certainly have lots into it, never mind the SR 643 chassis!!! Best. G.

Best of luck selling your SR, hope you get what you're looking for out of it. I saw the ad and you certainly have lots into it, never mind the SR 643 chassis!!! Best. G.

montynormand

Member

wanna write me a check Gorkon? i think you would look pretty good on my ol rocket

RJH

New member

my GPX never had piston problems...it was certinally running very clean...in mod stock..same thing. In pro - the factory piston lasted only 2 to 3 races.. light weight ...skirt cracked...never the top...

Take the high speed air jet out if you are running 40's miks or bigger

If you have m's you beter have lots of pistons...they only work right for 3 races +/-...

Take the high speed air jet out if you are running 40's miks or bigger

If you have m's you beter have lots of pistons...they only work right for 3 races +/-...

Gorkon

New member

Unfortunately I don't have her anymore. But when we were racing and we would go out in the morning and start tuning it, if the temperature changed too much before noon and between heats, she'd smoke a piston. I was only running superstock so the sled was stock other than carbides, pics and handlebar loop. The mechanic and the guy who actually had his hands in there was an old motocross guy so I don't know exactly what he was doing. She was definitely on the edge though and I never complained because my GPX was always the fastest stock GPX at the track on any given day. I would always enter it in 340 Mod stock and 440 superstock as well and would often wind up placing in those classes too. It was fun.

I would take that old girl Monty, but at present wouldn't have anyplace to play with it. We're hoping to have something going for some sort of track this year. Besides, next week I'm ordering a new Apex XTX and you know I gotta have that! LOL Thanks. G.

I would take that old girl Monty, but at present wouldn't have anyplace to play with it. We're hoping to have something going for some sort of track this year. Besides, next week I'm ordering a new Apex XTX and you know I gotta have that! LOL Thanks. G.

RJH

New member

Where on the track did it lock up..not that it matters today...

Gorkon

New member

I don't recall it locking up or where on the track it went. I recall it running like a demon and then all of a sudden you could feel a loss of power and hear it detonating. At that point I would always get out of it immediately as I knew exactly what was happening. I could usually limp it back to the pits. It was never more than a new piston and rings and sometimes cleaning some aluminum from the piston off the head with some muratic acid.

The piston was clearly melting which would have been eliminated by a thermal barrier coating. Thanks. G.

The piston was clearly melting which would have been eliminated by a thermal barrier coating. Thanks. G.

RJH

New member

in SS..what carb did you use...

Maybe the coatings would have helped..but only as a crutch.

mine had stock carbs...the engine never had a problem...and it was the fastest...in its day...

However..I used coated vertex (vortex I forget) pistons (nice pistons) when my kid won his 125 shifter kart championship...engine ran at 14,000+

mod stock

Maybe the coatings would have helped..but only as a crutch.

mine had stock carbs...the engine never had a problem...and it was the fastest...in its day...

However..I used coated vertex (vortex I forget) pistons (nice pistons) when my kid won his 125 shifter kart championship...engine ran at 14,000+

mod stock

Last edited:

Gorkon

New member

Stock GPX carbs for SS. I don't understand crutch!? The heat that melted the piston could not have done so and would have had to exit the cylinder with the exhaust. It would have saved the piston.

Have you ever gone to Swain Technologies website and read through their material and looked at the demonstration with the blow torch on the top of the piston? Good information and I believe the reason for the popularity of the coatings with high buck race teams in all kinds of racing.

As I said previously, the only problem that I can see, is taking longer for the piston to get up to proper operating temperature. Nowadays with these fancy powdered metal forgings, pistons run closer tolerances because they don't grow as much when they get hot. With an old cast piston using the coating, the piston will still grow the same amount, just take longer to do so.

In my case with this 338 SS, especially since I will be adapting new carbs to this engine, I see it as providing protection from meltdown whilst getting it dialed in, then, one could probably get away with running it leaner and closer to the edge than would normally be possible without the threat of melting it down.

It blows me away that your GPX didn't eat pistons in racing, I couldn't even count the pistons I went through! Thanks. G.

Have you ever gone to Swain Technologies website and read through their material and looked at the demonstration with the blow torch on the top of the piston? Good information and I believe the reason for the popularity of the coatings with high buck race teams in all kinds of racing.

As I said previously, the only problem that I can see, is taking longer for the piston to get up to proper operating temperature. Nowadays with these fancy powdered metal forgings, pistons run closer tolerances because they don't grow as much when they get hot. With an old cast piston using the coating, the piston will still grow the same amount, just take longer to do so.

In my case with this 338 SS, especially since I will be adapting new carbs to this engine, I see it as providing protection from meltdown whilst getting it dialed in, then, one could probably get away with running it leaner and closer to the edge than would normally be possible without the threat of melting it down.

It blows me away that your GPX didn't eat pistons in racing, I couldn't even count the pistons I went through! Thanks. G.

Last edited:

dynofun

New member

- Joined

- Nov 14, 2005

- Messages

- 355

Gorkon said:Stock GPX carbs for SS. I don't understand crutch!? The heat that melted the piston could not have done so and would have had to exit the cylinder with the exhaust. It would have saved the piston.

Have you ever gone to Swain Technologies website and read through their material and looked at the demonstration with the blow torch on the top of the piston? Good information and I believe the reason for the popularity of the coatings with high buck race teams in all kinds of racing.

As I said previously, the only problem that I can see, is taking longer for the piston to get up to proper operating temperature. Nowadays with these fancy powdered metal forgings, pistons run closer tolerances because they don't grow as much when they get hot. With an old cast piston using the coating, the piston will still grow the same amount, just take longer to do so.

In my case with this 338 SS, especially since I will be adapting new barbs to this engine, I see it as providing protection from meltdown whilst getting it dialed in, then, one could probably get away with running it leaner and closer to the edge than would normally be possible without the threat of melting it down.

It blows me away that your GPX didn't eat pistons in racing, I couldn't even count the pistons I went through! Thanks. G.

Gorkon what did you use for gas and oil? What is the sled in your avatar?

RJH

New member

We raced on hard ice...no drag...heavy load would certinally seize a Yamaha on the edge.

I ran 1 set of pistons and rings all year in stock 340 and 440. 3 heat races and a final..0most weekends...in 340, 400 and 440 + mod at the circuits that alowed it.

The engine ran at factory recommended rpm (didn't lug it).

I would have the pipe done. The pipe heat affects the carb...once it cools..and that happens fast..the jetting is off. My sleds were always at WOT..no trail riding.

Coated pistons are good...do it for sure...but if its going to seize it will...the coating ( a backdoor way or crutch) may allow a few more degrees...

As you are aware..the stock carbs 1/64 of a turn off will take you from 1st to 5th.

Lugging and seizing.

The secondary had to do a ton of work to overcome the weak primary. Just because it ran at factory rpm ..so doesn't mean it was..deep down. We used the GYT clutch and the secondary was really tight...

It will still run at the same rpm with stock...but it was actually lugging or just off the power line.

I bet we got another 10 mph with it would up.. I have a feeling...your sled is lugging...if you didn't have that setup..= seize...

I ran 1 set of pistons and rings all year in stock 340 and 440. 3 heat races and a final..0most weekends...in 340, 400 and 440 + mod at the circuits that alowed it.

The engine ran at factory recommended rpm (didn't lug it).

I would have the pipe done. The pipe heat affects the carb...once it cools..and that happens fast..the jetting is off. My sleds were always at WOT..no trail riding.

Coated pistons are good...do it for sure...but if its going to seize it will...the coating ( a backdoor way or crutch) may allow a few more degrees...

As you are aware..the stock carbs 1/64 of a turn off will take you from 1st to 5th.

Lugging and seizing.

The secondary had to do a ton of work to overcome the weak primary. Just because it ran at factory rpm ..so doesn't mean it was..deep down. We used the GYT clutch and the secondary was really tight...

It will still run at the same rpm with stock...but it was actually lugging or just off the power line.

I bet we got another 10 mph with it would up.. I have a feeling...your sled is lugging...if you didn't have that setup..= seize...

Gorkon

New member

I could not possibly remember what fuel was used, premium from the pumps I'm sure. The sled in the avatar is a Yamaha Motor Canada 75 GPX factory race sled, not mine unfortunately.

The clutching is the one thing that the mechanic clearly did not understand, nor I at the time for that matter. I used the stock clutching and it was great at the start of the season and I would be very strong off the line and first into the turn, you know how important that is. As the season progressed it started bogging on the line and I would have to fight my way through the field, and now that you mention it, that is when it started to melt pistons. I know now that I should have at least popped new springs into the clutches which I did not know then.

One late night after wrenching on the sled to prepare for the finals on Sunday and listening to my reports of what it was doing, the mechanic and my race team mate, who were always experimenting with stuff suggested cutting my secondary spring down to solve the problem. They were adamant and I argued with them that it made no sense since all I wanted to do was make it work like it did at the start of the season and forbade them to do it. The next day the sled was horrible and they told me that they cut the spring after I left for home. I was furious, but installed a new spring and then started figuring out that was I needed at minimum as the sled worked much better. It still was not up to snuff as it was new, but that was obviously the primary spring, at minimum, that should have been replaced as well. I never realized till not that long ago how fast these springs lose their tension. I replace springs regularily now, especially if they got hot.

As I said, I don't recall it seizing because I got out of it immediately, I understood what was happening and no, not all the tracks were as good as one would have liked so the sled was definitely working at times. Now that I think about it, I don't recall melting it down on the fast ice tracks. Thanks Bob. Best. G.

The clutching is the one thing that the mechanic clearly did not understand, nor I at the time for that matter. I used the stock clutching and it was great at the start of the season and I would be very strong off the line and first into the turn, you know how important that is. As the season progressed it started bogging on the line and I would have to fight my way through the field, and now that you mention it, that is when it started to melt pistons. I know now that I should have at least popped new springs into the clutches which I did not know then.

One late night after wrenching on the sled to prepare for the finals on Sunday and listening to my reports of what it was doing, the mechanic and my race team mate, who were always experimenting with stuff suggested cutting my secondary spring down to solve the problem. They were adamant and I argued with them that it made no sense since all I wanted to do was make it work like it did at the start of the season and forbade them to do it. The next day the sled was horrible and they told me that they cut the spring after I left for home. I was furious, but installed a new spring and then started figuring out that was I needed at minimum as the sled worked much better. It still was not up to snuff as it was new, but that was obviously the primary spring, at minimum, that should have been replaced as well. I never realized till not that long ago how fast these springs lose their tension. I replace springs regularily now, especially if they got hot.

As I said, I don't recall it seizing because I got out of it immediately, I understood what was happening and no, not all the tracks were as good as one would have liked so the sled was definitely working at times. Now that I think about it, I don't recall melting it down on the fast ice tracks. Thanks Bob. Best. G.

RJH

New member

It seems a lot of Yamaha engines..seize..if lugged.

Did I mentuin we ran GYT springs in stock.

In mod stock..the GYT secondary was wound beyond belief.

I must have a spring fettish...we used the bigger GP spirngs in the skid as well...wound up further with hockey sticks...

Did I mentuin we ran GYT springs in stock.

In mod stock..the GYT secondary was wound beyond belief.

I must have a spring fettish...we used the bigger GP spirngs in the skid as well...wound up further with hockey sticks...

Gorkon

New member

I have some fetish's, but they have nothing to do with springs! LOL Took my little motor to show the porting guy the other day to see what he wanted to do before sending the pistons off for coating. He told me to wait until he is done as these pistons have the transfer port in them. I gotta get the bottom end assembled first and that means I have to get the modifications done asap for the new stator before that can happen.

Piston coatings, ceramic coated pipes, CDI and hopefully, Lectrons with a balance bottle and a Phazer skid! Yippee, can't wait! Little bugger should haul the mail! Got some ideas for clutching too!

Piston coatings, ceramic coated pipes, CDI and hopefully, Lectrons with a balance bottle and a Phazer skid! Yippee, can't wait! Little bugger should haul the mail! Got some ideas for clutching too!

toydoc

Member

Add transfer port to a piston in a piston port motor or reed motor?

I don't know how well flat slide carbs will work with race porring on a piston port motor. Piston port motors have some reverse pulse in the intake with race porting (spit back, gas fog infront of the carb). That reverse pules with a short intake and strong signal of a flat slide carb could cause jetting issues.

I don't know how well flat slide carbs will work with race porring on a piston port motor. Piston port motors have some reverse pulse in the intake with race porting (spit back, gas fog infront of the carb). That reverse pules with a short intake and strong signal of a flat slide carb could cause jetting issues.

RJH

New member

I do have opinions..sorry…..however they are based on successful experiences..

First off..if it’s a GPX..I would leave it stock..maybe take out a head gasket. The pipes are great. Needs a P85 and an SRX secondary +/-. You can get,,, more snoot out of other 338’s

Lectron…love that carb..its fantastic…but if you can’t get a full set of jets for it..then its no good..so stick to a VM. TM..is OK as well. TMX or TMXx have a fixed tube and can’t (well if your lucky) you can) be tuned to other engines...

I’m sorry..but a flat slide works just fine on piston port..if its spits back..its because some pretend a tuner with the *** hanging out his pants took a grinder to it…

Mine worked just fine..

First off..if it’s a GPX..I would leave it stock..maybe take out a head gasket. The pipes are great. Needs a P85 and an SRX secondary +/-. You can get,,, more snoot out of other 338’s

Lectron…love that carb..its fantastic…but if you can’t get a full set of jets for it..then its no good..so stick to a VM. TM..is OK as well. TMX or TMXx have a fixed tube and can’t (well if your lucky) you can) be tuned to other engines...

I’m sorry..but a flat slide works just fine on piston port..if its spits back..its because some pretend a tuner with the *** hanging out his pants took a grinder to it…

Mine worked just fine..

Last edited:

Gorkon

New member

Its a 70 SS 338 and it already has the transfer port in the piston and cylinder wall. One of the reasons for considering the Lectron is the stronger vacum signal so I was thinking that it should just fine on a piston port. Just unsure about the balance bottle.

Can't get jets? What about from Lectron? G.

Can't get jets? What about from Lectron? G.

RJH

New member

Geez..I wish you had a different picture..it was so much fun driving mine...wish I would have enjoyed it even more...at the time...

Lectron mixes the fuel well is why its good. I'm talking all the jets..its a balance program...jetting is. Forget the balance tube.

You wanna go fast get a pair of Dellorto's...flat slides. They are way too expensive...but work like a TMXx with VM adjustablity. I have about every jet for 32's +/-...

We could make a lean mid range with a rich main or rich mid with a lean top.

338..you can get that one going..have fun...

Lectron mixes the fuel well is why its good. I'm talking all the jets..its a balance program...jetting is. Forget the balance tube.

You wanna go fast get a pair of Dellorto's...flat slides. They are way too expensive...but work like a TMXx with VM adjustablity. I have about every jet for 32's +/-...

We could make a lean mid range with a rich main or rich mid with a lean top.

338..you can get that one going..have fun...

toydoc

Member

RJH said:I do have opinions..sorry…..however they are based on successful experiences..

First off..if it’s a GPX..I would leave it stock..maybe take out a head gasket. The pipes are great. Needs a P85 and an SRX secondary +/-. You can get,,, more snoot out of other 338’s

Lectron…love that carb..its fantastic…but if you can’t get a full set of jets for it..then its no good..so stick to a VM. TM..is OK as well. TMX or TMXx have a fixed tube and can’t (well if your lucky) you can) be tuned to other engines...

I’m sorry..but a flat slide works just fine on piston port..if its spits back..its because some pretend a tuner with the *** hanging out his pants took a grinder to it…

Mine worked just fine..

So ACE you have the flat slides working so well you still recommend using a round slide VM over a flat slide

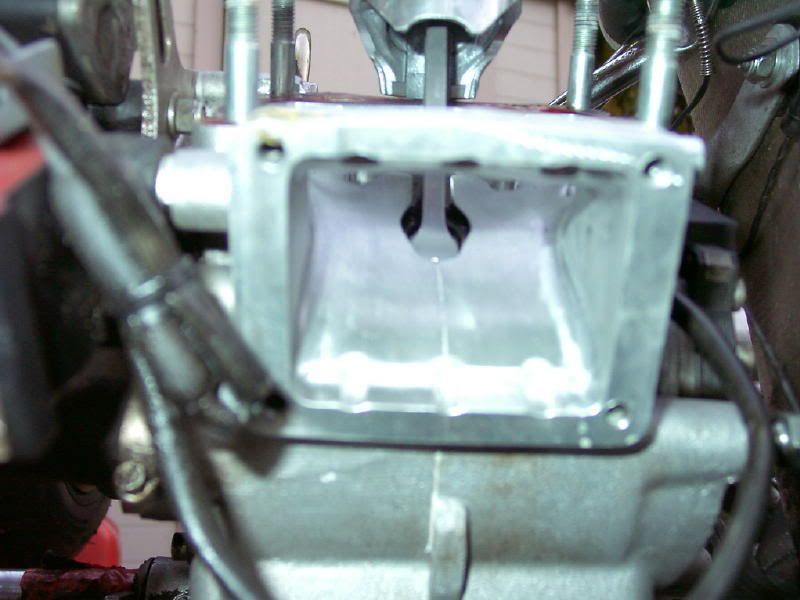

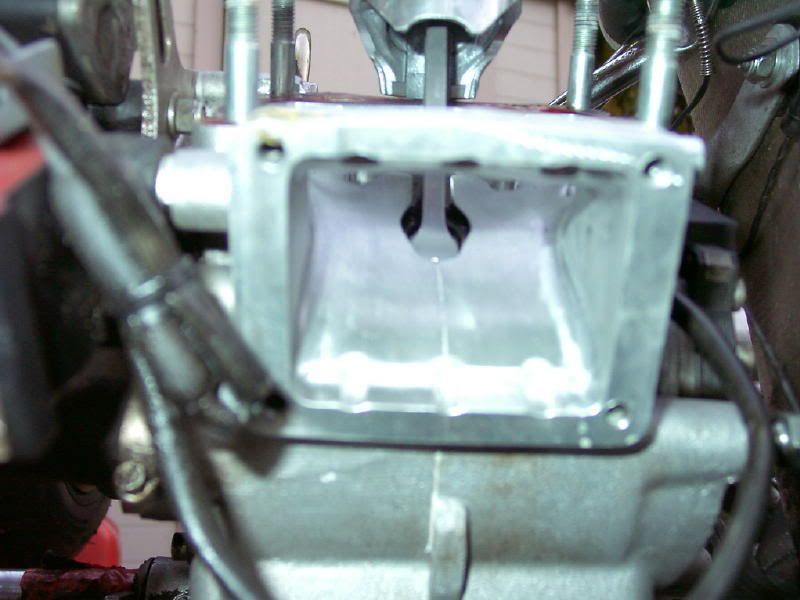

What motor do you run a flat slide on? What size flat slide and who's carb? How about a picture of your setup so we can learn something from a pro?