toydoc

Member

Gorkon said:Its a 70 SS 338 and it already has the transfer port in the piston and cylinder wall. One of the reasons for considering the Lectron is the stronger vacum signal so I was thinking that it should just fine on a piston port. Just unsure about the balance bottle.

Can't get jets? What about from Lectron? G.

For what it's worth, we made a billet balance tube for the SSR motor and lost power on the dyno

toydoc

Member

Also made billet carb spacers with O-ring seals, all size and shape. None added HP on the dyno. Made billet air horns for some custom 46mm round slides that did add a bit of hp

RJH

New member

Ace…haven’t been called that before.

I can optimize a flat slide to work better than a round slide…if I have the jets. Just to get that straight.

However..today’s Asian TMX carbs called the TMXx are built for a specific engine and model. The fuel flow is engineered to what the factory wants ..that is either high or low fuel flow thru the needle profile and tube I.D.

So…even thou the TMXx may have the best performance potential…it may not be able to optimize the performance on another engine…so..I would use a VM and go faster…

I raced the factory SSR (Larry Ohmans ride..when he left the camp) ) for a weekend. The engine was the same basic configuration as the stocker..but lighter pistons and trick pipe and monster 54 or 56 mm carb.

It was a proto type butterfly with a float bowl. Very very fast….made the stocker feel like a 250.

They lowered the engine in the pro sled …could they not tell that was the wrong way to go..…the stocker steered much better.

We also ran an SSR with a 340.

I have very few pictures dude…I was more interested in winning than fame ..at the time.

I can optimize a flat slide to work better than a round slide…if I have the jets. Just to get that straight.

However..today’s Asian TMX carbs called the TMXx are built for a specific engine and model. The fuel flow is engineered to what the factory wants ..that is either high or low fuel flow thru the needle profile and tube I.D.

So…even thou the TMXx may have the best performance potential…it may not be able to optimize the performance on another engine…so..I would use a VM and go faster…

I raced the factory SSR (Larry Ohmans ride..when he left the camp) ) for a weekend. The engine was the same basic configuration as the stocker..but lighter pistons and trick pipe and monster 54 or 56 mm carb.

It was a proto type butterfly with a float bowl. Very very fast….made the stocker feel like a 250.

They lowered the engine in the pro sled …could they not tell that was the wrong way to go..…the stocker steered much better.

We also ran an SSR with a 340.

I have very few pictures dude…I was more interested in winning than fame ..at the time.

Last edited:

dynofun

New member

- Joined

- Nov 14, 2005

- Messages

- 355

Wow doc, when did ya do all that work to make a balance tube? We just put stock engines on the dyno and tried them over and over taking it off and putting it on. No difference most of the time but sometimes maybe "felt" better in the low end area which we never cared about.

toydoc

Member

RJH said:Ace…haven’t been called that before.

I can optimize a flat slide to work better than a round slide…if I have the jets. Just to get that straight.

However..today’s Asian TMX carbs called the TMXx are built for a specific engine and model. The fuel flow is engineered to what the factory wants ..that is either high or low fuel flow thru the needle profile and tube I.D.

So…even thou the TMXx may have the best performance potential…it may not be able to optimize the performance on another engine…so..I would use a VM and go faster…

I raced the factory SSR (Larry Ohmans ride..when he left the camp) ) for a weekend. The engine was the same basic configuration as the stocker..but lighter pistons and trick pipe and monster 54 or 56 mm carb.

It was a proto type butterfly with a float bowl. Very very fast….made the stocker feel like a 250.

They lowered the engine in the pro sled …could they not tell that was the wrong way to go..…the stocker steered much better.

We also ran an SSR with a 340.

I have very few pictures dude…I was more interested in winning than fame ..at the time.

I'm trying not to bash you, but you seem to jump on me with your post "but a flat slide works just fine on piston port..if its spits back..its because some pretend a tuner with the *** hanging out his pants took a grinder to it"

If you have them working thats great. List what you have and whats working because I'd really like to know and learn from it (i'm allways learning, and can never know it all).

Lots of us can tune a carb, flat or round. Some of us even use a dyno with BSFC to dial it in just right. Right now I run VM's, TM's, TMX's, Megatrons, Crankshop's and CPC. All work just fine on reed motors of all size cc. No issue with fixed needel jet on the TMX, only issue was to bore them to 40mm with a fixed jet. We even got around that issue and now have 40mm TMX's.

You make a point to say I'm wrong (lots of times I am) and you have flat working fine. Then in the same post you list all the flats that you couldn't get to work because you ran out of tunning parts and just run a round slide. I posted why you maybe having a hard time tunning them because of port overlap. On a race piston port motor, you can get two draws of fuel from the needel jet on one stroke. That issue is worse with a flat right up on the intake. They may work better if they are moved back with a long intake, but i'm not sure. I would get out all the spacers I have and try them all over with flat slide and see if they work.

I really like the race storys you have. Thats cool stuff, but Gorkon was talking about running flats and I wasn't sure if that was the best way to go on his motor. In the end you and I are saying the same thing, we would run VM's.

toydoc

Member

dynofun said:Wow doc, when did ya do all that work to make a balance tube? We just put stock engines on the dyno and tried them over and over taking it off and putting it on. No difference most of the time but sometimes maybe "felt" better in the low end area which we never cared about.

All very old stuff. My box of ideas that didn't work (broken dreams

)

)RJH

New member

Ya..I tried to say it without bashing…too bad you took it that way. I do like that you are thinking hard about this stuff…enjoyed your pictures.

If the pistons have been cut..there is no way to stop spit back…In addition..if one sector of the carb circuit is rich…eg slide..needle..fuel will glob and look like spit back at high speed. My Yamaha’s ran against rotary and reed valves..no problem…

A bored carb cannot be tuned to optimum efficiency.

You need to jet race day…not on a dyno…in my day…we may change every heat race and final. In our 125 shifter kart days…we would sometimes flatten the mid range so the kid wouldn’t spin coming off a turn in the early morning damp conditions.

Here is good trick…take out the MJ (the least important jet) and drive it around and feel..you will be amazed…what you can learn. AMAZED...

Flat slide or round..no difference. They were invented by Suzuki as the VM didn’t fit their bike. As a benefit..they flow better. However…to get advantage…you need a TMXx as the American TMX..is way too sloppy in the slide area.

Most of my race engines were stock….and I tuned to that engine. The only one I did was when Yamaha got me a tri-moto 175 to run against the 250’s. We just welded a 6 petal reed block, 34 mm carb, on it and a Can Am 250 pipe. It was faster than any Honda 250.

Also..when we moved into mod stock..some famous engine tuner of the day said he would do my engine for free..for advertising….I ran it one weekend and put the stock GYT jugs back on…it would not tune to optimum performance.

Mod Stock

If the pistons have been cut..there is no way to stop spit back…In addition..if one sector of the carb circuit is rich…eg slide..needle..fuel will glob and look like spit back at high speed. My Yamaha’s ran against rotary and reed valves..no problem…

A bored carb cannot be tuned to optimum efficiency.

You need to jet race day…not on a dyno…in my day…we may change every heat race and final. In our 125 shifter kart days…we would sometimes flatten the mid range so the kid wouldn’t spin coming off a turn in the early morning damp conditions.

Here is good trick…take out the MJ (the least important jet) and drive it around and feel..you will be amazed…what you can learn. AMAZED...

Flat slide or round..no difference. They were invented by Suzuki as the VM didn’t fit their bike. As a benefit..they flow better. However…to get advantage…you need a TMXx as the American TMX..is way too sloppy in the slide area.

Most of my race engines were stock….and I tuned to that engine. The only one I did was when Yamaha got me a tri-moto 175 to run against the 250’s. We just welded a 6 petal reed block, 34 mm carb, on it and a Can Am 250 pipe. It was faster than any Honda 250.

Also..when we moved into mod stock..some famous engine tuner of the day said he would do my engine for free..for advertising….I ran it one weekend and put the stock GYT jugs back on…it would not tune to optimum performance.

Mod Stock

Last edited:

Gorkon

New member

That is good valuable information guys. ToyDoc, you answered a couple of questions for me with the pics as I was curious as to what could be proven using the balance tube, so thanks for that. The other thing that I learned here is and something that I was curious about, was spacing.

Since the Kiehin carbs for this engine are dinosaurs with no parts availability and the set I have is incomplete, I had decided long ago to update to modern carbs and build my own linkage for the oil pump, but had no experience to draw on to make any sort of decision as to which carb to use or exactly how to go about it.

While thinking about building an adapter to mount the carbs I wondered what effect moving them further away from the engine would have, since the adapter will necessitate that, by a little bit anyway. Sounds like that will actually help my cause.

My original thought was flat slides with K&N's and maybe even some Boyesen power wings, any experience with those? The results with the air horns is interesting. I did go to Lectron's site and read about their carbs and thought they would probably work well because of how they work for strong vacum signal on the venturi.

Are the Dollorto's not roundslide carbs? Or do they make flats as well?

I am watching here and listening carefully before making any decision, but keep in mind that this sled will not be doing all out competition but may find itself in the odd drag race with a certain 10 year old aboard. We felt we might as well modify it to make work as good as possible as they won't allow it to run stock ovals with the factory pipes anyway. The boy will probably trail ride it a bit too. (He's promised me he will wear hearing protection whenever riding it! We'll see how that goes.) So I don't want it too finicky. We would like to see it go to the drags and with his weight, give 500's fits! That'd be fun.

You guys have far more experience and expertise than I do with this stuff, which is invaluable to me. I raced yes, but I was more like Donald Sutherland's character in Kelly's Heroes, "Hey man, I don't know what makes em work, I just drive em." LOL

Right now my biggest problem is upgrading it to a taper end crank so I can run a modern primary and CDI. Still have research to do as to what to do with the crank but don't have time yet as I'm working hard on making money not the problem. Thanks for all the excellent posts and help. We're really looking forward to completion of this project around here and having fun. Best. G.

Since the Kiehin carbs for this engine are dinosaurs with no parts availability and the set I have is incomplete, I had decided long ago to update to modern carbs and build my own linkage for the oil pump, but had no experience to draw on to make any sort of decision as to which carb to use or exactly how to go about it.

While thinking about building an adapter to mount the carbs I wondered what effect moving them further away from the engine would have, since the adapter will necessitate that, by a little bit anyway. Sounds like that will actually help my cause.

My original thought was flat slides with K&N's and maybe even some Boyesen power wings, any experience with those? The results with the air horns is interesting. I did go to Lectron's site and read about their carbs and thought they would probably work well because of how they work for strong vacum signal on the venturi.

Are the Dollorto's not roundslide carbs? Or do they make flats as well?

I am watching here and listening carefully before making any decision, but keep in mind that this sled will not be doing all out competition but may find itself in the odd drag race with a certain 10 year old aboard. We felt we might as well modify it to make work as good as possible as they won't allow it to run stock ovals with the factory pipes anyway. The boy will probably trail ride it a bit too. (He's promised me he will wear hearing protection whenever riding it! We'll see how that goes.) So I don't want it too finicky. We would like to see it go to the drags and with his weight, give 500's fits! That'd be fun.

You guys have far more experience and expertise than I do with this stuff, which is invaluable to me. I raced yes, but I was more like Donald Sutherland's character in Kelly's Heroes, "Hey man, I don't know what makes em work, I just drive em." LOL

Right now my biggest problem is upgrading it to a taper end crank so I can run a modern primary and CDI. Still have research to do as to what to do with the crank but don't have time yet as I'm working hard on making money not the problem. Thanks for all the excellent posts and help. We're really looking forward to completion of this project around here and having fun. Best. G.

RJH

New member

They make both..here are a few carb things I did for a sponsor.

Fantastic carb...it is..

http://www.ekartingnews.com/news_info.php?n=2235

http://www.ekartingnews.com/news_info.php?n=2336

http://www.ekartingnews.com/news_info.php?n=2442

I didn't do part 4..too much info..that would have been...

Fantastic carb...it is..

http://www.ekartingnews.com/news_info.php?n=2235

http://www.ekartingnews.com/news_info.php?n=2336

http://www.ekartingnews.com/news_info.php?n=2442

I didn't do part 4..too much info..that would have been...

toydoc

Member

RJH said:Ya..I tried to say it without bashing…too bad you took it that way. I do like that you are thinking hard about this stuff…enjoyed your pictures.

If the pistons have been cut..there is no way to stop spit back…In addition..if one sector of the carb circuit is rich…eg slide..needle..fuel will glob and look like spit back at high speed. My Yamaha’s ran against rotary and reed valves..no problem…

A bored carb cannot be tuned to optimum efficiency.

You need to jet race day…not on a dyno…in my day…we may change every heat race and final. In our 125 shifter kart days…we would sometimes flatten the mid range so the kid wouldn’t spin coming off a turn in the early morning damp conditions.

Here is good trick…take out the MJ (the least important jet) and drive it around and feel..you will be amazed…what you can learn. AMAZED...

Flat slide or round..no difference. They were invented by Suzuki as the VM didn’t fit their bike. As a benefit..they flow better. However…to get advantage…you need a TMXx as the American TMX..is way too sloppy in the slide area.

Most of my race engines were stock….and I tuned to that engine. The only one I did was when Yamaha got me a tri-moto 175 to run against the 250’s. We just welded a 6 petal reed block, 34 mm carb, on it and a Can Am 250 pipe. It was faster than any Honda 250.

Also..when we moved into mod stock..some famous engine tuner of the day said he would do my engine for free..for advertising….I ran it one weekend and put the stock GYT jugs back on…it would not tune to optimum performance.

A stock 8H0 yamaha SSR piston is cut down on the intake. Every SR motor called for cutting the intake in all 3 SR motors, 292, 433 and 643 right from Yamaha. So they will have port overlap or spit back with factory race spec. It's not a case of "if its spits back..its because some pretend a tuner with the *** hanging out his pants took a grinder to it". If that was the case, it would be the guys from Japan with the grinder and *** hanging out. Now we are on the same page with port overlap and what it can do.

I have not had any issue with slide area on the TMX. The two peice TM can have that issue (I don't care for them). If you run them in summer toys, MX bikes, ATV's, they can wear the friction coat off the slide and wear the slide. On sleds they seem to last way longer. I've seen 10,000 miles on snowmobile TMX slide that still look good.

I like the idea of running without a MJ. But the TMX is the only fixed needle jet. The others use the MJ to hold the needle jet in place. So wouldn't a running a big main to start tunning do the same thing? Safer, that way the slide can't get hung up (open throttle) if the needle jet was to ride up with the slide?

Not only do we tune at the dyno but at the track we made a auxiliary billet power jet that you can adjust when on the track racing. It's cable setup to the handle bars, you don't even slow down to adjust the jetting. Tune at each turn. Don't even open the hood. They are stock 44mm bored 49.5mm carbs with hand made billet slides that work very well.

Last edited:

toydoc

Member

RJH said:They make both..here are a few carb things I did for a sponsor.

Fantastic carb...it is..

http://www.ekartingnews.com/news_info.php?n=2235

http://www.ekartingnews.com/news_info.php?n=2336

http://www.ekartingnews.com/news_info.php?n=2442

I didn't do part 4..too much info..that would have been...

That is some cool stuff. Lots of work on your part, both in the shop and on the track. Thanks for the link.

toydoc

Member

Gorkon said:That is good valuable information guys. ToyDoc, you answered a couple of questions for me with the pics as I was curious as to what could be proven using the balance tube, so thanks for that. The other thing that I learned here is and something that I was curious about, was spacing.

Since the Kiehin carbs for this engine are dinosaurs with no parts availability and the set I have is incomplete, I had decided long ago to update to modern carbs and build my own linkage for the oil pump, but had no experience to draw on to make any sort of decision as to which carb to use or exactly how to go about it.

While thinking about building an adapter to mount the carbs I wondered what effect moving them further away from the engine would have, since the adapter will necessitate that, by a little bit anyway. Sounds like that will actually help my cause.

My original thought was flat slides with K&N's and maybe even some Boyesen power wings, any experience with those? The results with the air horns is interesting. I did go to Lectron's site and read about their carbs and thought they would probably work well because of how they work for strong vacum signal on the venturi.

Are the Dollorto's not roundslide carbs? Or do they make flats as well?

I am watching here and listening carefully before making any decision, but keep in mind that this sled will not be doing all out competition but may find itself in the odd drag race with a certain 10 year old aboard. We felt we might as well modify it to make work as good as possible as they won't allow it to run stock ovals with the factory pipes anyway. The boy will probably trail ride it a bit too. (He's promised me he will wear hearing protection whenever riding it! We'll see how that goes.) So I don't want it too finicky. We would like to see it go to the drags and with his weight, give 500's fits! That'd be fun.

You guys have far more experience and expertise than I do with this stuff, which is invaluable to me. I raced yes, but I was more like Donald Sutherland's character in Kelly's Heroes, "Hey man, I don't know what makes em work, I just drive em." LOL

Right now my biggest problem is upgrading it to a taper end crank so I can run a modern primary and CDI. Still have research to do as to what to do with the crank but don't have time yet as I'm working hard on making money not the problem. Thanks for all the excellent posts and help. We're really looking forward to completion of this project around here and having fun. Best. G.

G, you have lots of good ideas. I'm not saying don't try them. I'd get your motor built. Get it to run good with round carbs. Then try your ideas one at a time to see what works or not. Lots of people should get you close with round carbs and thats good. When you start with lectron and odd things you maybe on your own for help and if it won't run right, thats no fun.

If your motor has reeds, you have alot more mods to pick from

Last edited:

Gorkon

New member

Wow! Thanks so much for the links Bob, that should help me immensely.

ToyDoc, thanks for the input, you may well be absolutely correct, though at this time I really wouldn't know. Perhaps after reading the information in the links Bob has provided? Unfortunately I don't have reeds, but part of the fun of this for me, is to take a dinosaur and infuse it with as much modern tech as I can and see what happens.

Back in 94 I built a 400 M Ford engine with 4bbl Cleveland heads, port plates and built my own lower intake to mate with a 302 EFI upper. Made my own injector bosses on the lathe and installed fuel injection on it, then built a pair of full length, equal length headers and had them ceramic coated. It works great, though I thought I was getting a mass air set up when I chose the cam and wound up stuck with speed density, so the computer doesn't really know what to with the cam in start up and she hunts a little. People said it wouldn't work, I knew it would, its just a reciprocating assembly that doesn't know how it gets it air and fuel and doesn't care! I had a blast building it though and most people can't believe it when they see it.

I'm so glad to see someone out there seriously running an SSR, how is that working out for you? We have no tracks in these parts and would have to travel half the continent to the nearest one, so I'm way out of touch with the scene. I had heard though that Rotax was the dominant force, is that true? Back in the day as I recall, the only reason Rotax was winning stuff really was because there was so many of them and very few Yamaha's.

Here's a shot of my creation, not a sled, but cool I think. I call it a 6.6 EFI Cleveland. lol Thanks again. G.

ToyDoc, thanks for the input, you may well be absolutely correct, though at this time I really wouldn't know. Perhaps after reading the information in the links Bob has provided? Unfortunately I don't have reeds, but part of the fun of this for me, is to take a dinosaur and infuse it with as much modern tech as I can and see what happens.

Back in 94 I built a 400 M Ford engine with 4bbl Cleveland heads, port plates and built my own lower intake to mate with a 302 EFI upper. Made my own injector bosses on the lathe and installed fuel injection on it, then built a pair of full length, equal length headers and had them ceramic coated. It works great, though I thought I was getting a mass air set up when I chose the cam and wound up stuck with speed density, so the computer doesn't really know what to with the cam in start up and she hunts a little. People said it wouldn't work, I knew it would, its just a reciprocating assembly that doesn't know how it gets it air and fuel and doesn't care! I had a blast building it though and most people can't believe it when they see it.

I'm so glad to see someone out there seriously running an SSR, how is that working out for you? We have no tracks in these parts and would have to travel half the continent to the nearest one, so I'm way out of touch with the scene. I had heard though that Rotax was the dominant force, is that true? Back in the day as I recall, the only reason Rotax was winning stuff really was because there was so many of them and very few Yamaha's.

Here's a shot of my creation, not a sled, but cool I think. I call it a 6.6 EFI Cleveland. lol Thanks again. G.

Attachments

toydoc

Member

Thats a cool setup. Back in 83~84 I made a Bogus Boss 302. Used the 302 windsor with 351 Cleveland 4V heads.

Looks like you have the truck intake. That would use a ECM, throttle position sensor, MAP sensor, and EGO for injector control. Don't think it used a mass air with that. What ECM and wiring are you using to run the injection?

Looks like you have the truck intake. That would use a ECM, throttle position sensor, MAP sensor, and EGO for injector control. Don't think it used a mass air with that. What ECM and wiring are you using to run the injection?

RJH

New member

Ya..G..made a lot of money just from being protested by rotax racers.

That big engine stuff…you guys just leave me in the weeds..amazing to do all that stuff… very impressed.

Woke up about 3AM thinking about your balance tube…TD. Couple things..the engineering behind the balance connection ..is for it to hold a pocket of ready to use mixed fuel…recovered from the stuff that doesn’t make it in. The other problem you have is… the rigid connection. You may be upsetting the carb resonance..(must be the same in the big block stuff you guys do)

I think that big hole in your tube,,is just too big. You need to add rubber in between to isolate the vibration.. from each other. Maybe make a chamber in the middle as well.

Gorkon..why don’t you find an old set of jugs…any brand..and cut the reed blocks off and weld them to your 338 jugs.

Racing today..I think the only cost effective..class is Formula 500. A class where cheaters cannot win in. Or champ..if you have the talent.

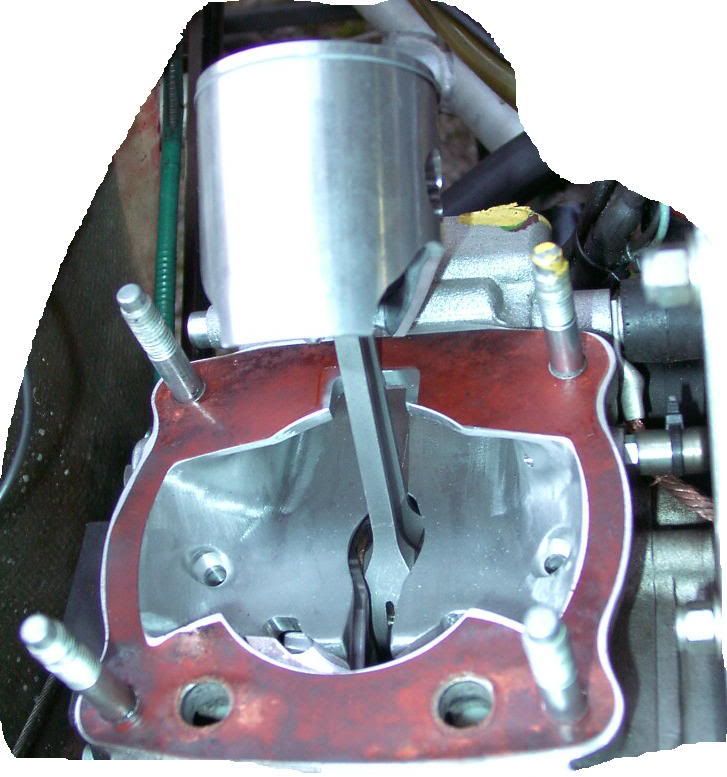

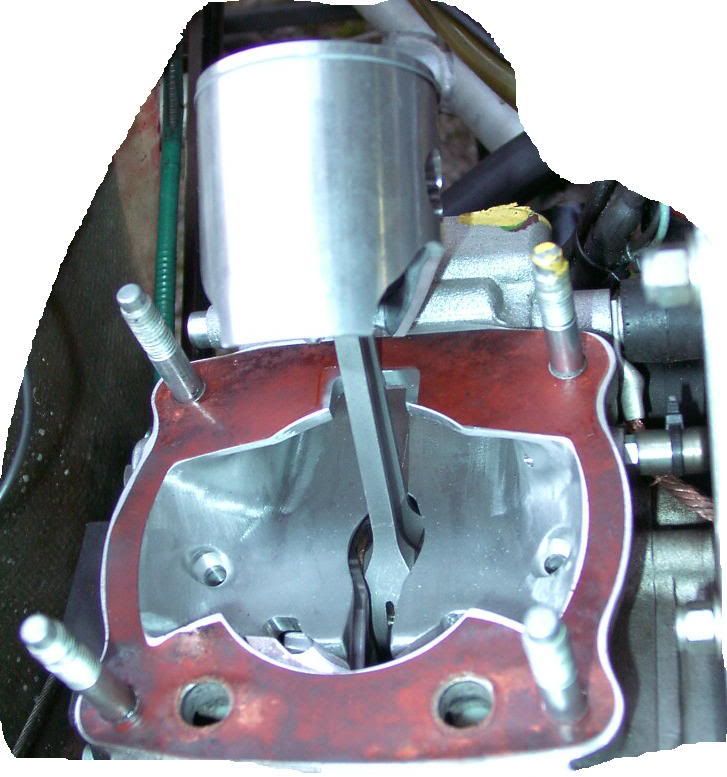

here is a good fast engine inside..no.. the gasket is not hanging in the case...notice the piston sides..

Exhaust side

That big engine stuff…you guys just leave me in the weeds..amazing to do all that stuff… very impressed.

Woke up about 3AM thinking about your balance tube…TD. Couple things..the engineering behind the balance connection ..is for it to hold a pocket of ready to use mixed fuel…recovered from the stuff that doesn’t make it in. The other problem you have is… the rigid connection. You may be upsetting the carb resonance..(must be the same in the big block stuff you guys do)

I think that big hole in your tube,,is just too big. You need to add rubber in between to isolate the vibration.. from each other. Maybe make a chamber in the middle as well.

Gorkon..why don’t you find an old set of jugs…any brand..and cut the reed blocks off and weld them to your 338 jugs.

Racing today..I think the only cost effective..class is Formula 500. A class where cheaters cannot win in. Or champ..if you have the talent.

here is a good fast engine inside..no.. the gasket is not hanging in the case...notice the piston sides..

Exhaust side

Gorkon

New member

It is a speed density set-up from an 89 460 5 sp. It was going/went into a 79 1 ton dually welding truck believe it or not. No I don't really have an "ID ten T" problem, though some people would argue that. Building a 70 Cleveland right now for my 70 Mustang, gonna use those new 3V alloy heads....too many projects or what?

Thought of welding on some reed blocks, but thought I could get away with the piston port if I could. I have had many suggest simply installing a newer 338, but it is a numbers matching unit and I would like to keep it that way if I can. Doesn't reconcile with being a restomod guy does it? lol

Making money from being protested by rotax racers, LMAO! That's funny. I don't recall how many times my GPX was protested and torn down to find nothing. lol Then I'd say something to them along the lines of the immortal words of my hero Kenny Roberts when asked for the reason for his dominance over Freddie Spencer, "Simple, my bike's a YAMAHA!" LOL!

As for aluminum welding projects, check out this clip! I'm pretty excited about it and already have it though I have not tried it out yet.

http://www.aluminumrepair.com/video_new.asp

Thanks guys. Best. G.

Thought of welding on some reed blocks, but thought I could get away with the piston port if I could. I have had many suggest simply installing a newer 338, but it is a numbers matching unit and I would like to keep it that way if I can. Doesn't reconcile with being a restomod guy does it? lol

Making money from being protested by rotax racers, LMAO! That's funny. I don't recall how many times my GPX was protested and torn down to find nothing. lol Then I'd say something to them along the lines of the immortal words of my hero Kenny Roberts when asked for the reason for his dominance over Freddie Spencer, "Simple, my bike's a YAMAHA!" LOL!

As for aluminum welding projects, check out this clip! I'm pretty excited about it and already have it though I have not tried it out yet.

http://www.aluminumrepair.com/video_new.asp

Thanks guys. Best. G.

RJH

New member

Kenny..a little over the top…but…I liked his practice style..using small engine powered bikes to practice on…you can feel when your putting load on the bike. Inventing the circle m..we could have done without that.

We have TIG and I can weld SS well..but not Aluminium..really have to do that soon. It was easier to give stuff to my buddy..to weld.

We have TIG and I can weld SS well..but not Aluminium..really have to do that soon. It was easier to give stuff to my buddy..to weld.

Gorkon

New member

In your articles you mentioned the 'wicked fast Circle M", yet everywhere they talk about how bad they were, that they did not last. What went on them exactly? Why would they work good for a bit then not? I don't really know anything about them, but it seems to me be another idea that could seriously benefit from modern tech. Just my two cents, I read the articles, but it gets a little deep for me, I didn't realize it was quite so complicated.

I have done tons of aluminum using every process and believe me, this HTS2000 is a godsend from what I can see. Should simplify many little jobs. Filling in that hole in the bottom of that can like is just about impossible to do anything like that otherwise!

Any ideas on which reed blocks to use or any pics of any examples done. You got me thinkin ya bugger. lol G.

I have done tons of aluminum using every process and believe me, this HTS2000 is a godsend from what I can see. Should simplify many little jobs. Filling in that hole in the bottom of that can like is just about impossible to do anything like that otherwise!

Any ideas on which reed blocks to use or any pics of any examples done. You got me thinkin ya bugger. lol G.

RJH

New member

Probably a 4 petal…its all just luck…when Bender got his factory big reed Pogo mod from Yamaha..the first thing he did was weld larger reed blocks The thing made substantially less HP. According to dynotech dyno.

A bad “M” would only be good for 4th maybe 3rd…they made me keep them on for most of my racing. The symptom..this is hard to comprehend..so just trust me…it was like a big mikini with too small high speed air jet. You just can’t get that crisp..it will seize before it goes faster. Balance is off.

We went thru several sets every year. Don’t give them another thought…lets go FI.

Up until last year or so..you never would have convinced me FI would work in bump machines..they have..we need to start to play with them…not aftermarket.

A bad “M” would only be good for 4th maybe 3rd…they made me keep them on for most of my racing. The symptom..this is hard to comprehend..so just trust me…it was like a big mikini with too small high speed air jet. You just can’t get that crisp..it will seize before it goes faster. Balance is off.

We went thru several sets every year. Don’t give them another thought…lets go FI.

Up until last year or so..you never would have convinced me FI would work in bump machines..they have..we need to start to play with them…not aftermarket.