i know here we go again with the old question but i'm just curious and new to the blue game. what i've got and what is recommended on here in the tech pages are two way different things and only having a small amount of snow to do small amount of testingso it really doesn't help, so here's what's in the sled. primary has y-w-y spring and 8dg-17605-00 weights with 2.4 gram rivet inner hole and .8 gram outer hole. secondary has hauck 49/41 helix with black spring red mark on spring and set at 3-3 or 60 degrees. i did just a 5-10 min short runs around grape-fields maybe hit 60 mph a few times not really hitting hard because of new belt but still hooked up really good, but this is the very first time on this machine so i really don't know what i should expect. i mean i know it should be fast lord knows i've watched enough you-tube video's but i was just curious of what you thought of this set-up. these short runs that i did where maybe 100 yards long and only half to three quarter throttle and it seemed to shift just fine. i guess my question is would this set-up do ok on the trails and an occassional field. i've already ordered the 51/43 helix, green sec. spring, y-s-y primary spring, 4.5 gram rivets and 8-dn weights so i'm just curious if this original crazy set-up would be fine. thanks for any help. p.s. i just want to ride the trails with the sled not drag race and i'm also running 144 studs up middle of track. thanks again

bluemonster1

LIFE MEMBER ONLY ONCE!!!

on my 02 srx I have stock weight 8DN-20's with stock primary spring.I have 4.5 inner hole and 5 g outer hole(added washer to rivet)I am now using stock 47 helix wrapped at 80.Pulls like a raped ape all the way to 100.I am geared down 1 tooth upper and do spin alot on take off..but when it hooks up..hang on.I tried my 51/43 in this cold weather and I started to over rev to much.I use the 51/43 when the temps get warm like close to 0 Celcius and rpm's drop back down,colder day I go back to 47 helix.I am really impressed on the way sled pulls.I have tried all different weights,springs,helix's over the years,I am happy with the stock setup as an overall setup.I gave up already to try and get an extra 1 to 3 mph and spending tons on money.Stock SRX with slight weight added to clutch and getting it to climb to 8500 on wot is perfect for me..I had the primary actually loaded up a little to heavy and motor would sort of lug and wouldn't open up right away..once I reduced some weight from tip ..total 53.2 grams down to 52.8 grams..she screams again.Worked for me.

hey thanks blue for the info. so just wondering, are you saying that you finally ended up at 4.5 inner and 5.0 at tip and that came out to be 52.8 total grams? and if so you say you added a washer to the stock rivet to get 5.0 how? i read somewhere on here that someone was using a 1/4" 28 thread bolt and washers' to get the right weight is this true? if so could i do the same to my current 8dg weights but add alittle to each weight to make up the 3 gram difference between 8 dg's and 8 dn's. i really like the profile of the 8 dg's but have not hit a full throttle run yet. it may make sense on paper but until you get to try it you never know right ? once again thanks and hope to hear from you.

bluemonster1

LIFE MEMBER ONLY ONCE!!!

SRX's should be running 8dn-00,or 8dn-10 or 8dn-20 weight.8dg's are in my SXR600 which are a lighter weight.What year is your SRX?

bluemonster1

LIFE MEMBER ONLY ONCE!!!

SRX 700

1998...8DN-00 -13.3 tip and 17.2 inner--use 15.6mm rollers

1999...8DN-10 -13.3 tip and 17.2 inner--use 15.0mm rollers

2000...8DN-20 -17.2 tip and 13.9 inner--use 15.6mm rollers

2001...8DN-20 -17.2 tip and 13.9 inner--use 15.6mm rollers

2002...8DN-20 -17.2 tip and 13.9 inner--use 15.6mm rollers

usually you get an over rev from factory stock setup.Today I was still over reving about 100 to 8600 rpm wot.But I am geared down so maybe that's why.If I put my stock top gear back on..it may be dead on.I could add a washer to my inner weight maybe because from a standstill when I punch it I still rev up past 8500 to 8600.Would like to hit 8200 and climb to 8500.Gonna be hard to get dead on..conditions change,temps change..etc.I now get a real good hole shot lifting ski's slightly and pulls like freight train to 100 to 105 on speedo.I know if I put my stock top gear back I may climb to 110..but the arm stretching pull in great.I don't do any racing,so the few extra mph is not important..getting to 100 quick is a great awesome feeling.

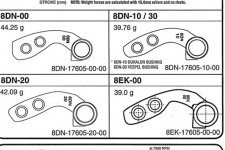

Here is the weight,rivet chart for you to check also.

1998...8DN-00 -13.3 tip and 17.2 inner--use 15.6mm rollers

1999...8DN-10 -13.3 tip and 17.2 inner--use 15.0mm rollers

2000...8DN-20 -17.2 tip and 13.9 inner--use 15.6mm rollers

2001...8DN-20 -17.2 tip and 13.9 inner--use 15.6mm rollers

2002...8DN-20 -17.2 tip and 13.9 inner--use 15.6mm rollers

usually you get an over rev from factory stock setup.Today I was still over reving about 100 to 8600 rpm wot.But I am geared down so maybe that's why.If I put my stock top gear back on..it may be dead on.I could add a washer to my inner weight maybe because from a standstill when I punch it I still rev up past 8500 to 8600.Would like to hit 8200 and climb to 8500.Gonna be hard to get dead on..conditions change,temps change..etc.I now get a real good hole shot lifting ski's slightly and pulls like freight train to 100 to 105 on speedo.I know if I put my stock top gear back I may climb to 110..but the arm stretching pull in great.I don't do any racing,so the few extra mph is not important..getting to 100 quick is a great awesome feeling.

Here is the weight,rivet chart for you to check also.

Attachments

Last edited:

ok here's the deal it's a 99 srx 700 and when i bought it i didn't know very much about them but spending the last 3 months reading all the tech spots and clutch charts' etc. i've learned alot. anyways the sled had been rode and not maintained and being ex. military maint. is like wiping your *** after a dump it's a good habit to have. anyways the clutch had stress cracks, lots of them, so i got on ebay and bought a clutch that was from a mountain max 700 not knowing the weights would be so lite so the old clutch is still usable for stock weights and rollers just the sheaves are shot. so anyways i was just curious about the current weights in the good clutch and cool thing is the primary spring is the same so no change there. but i'm still curious on how you added the .5 gram washer to your 4.5 gram rivet at the tip. and thanks for taking the time for the charts and pictures i've already found those in the tech area and stared at them for so long it hurts. but once again thanks for the help and if you could let me know about the added weight via the washer i'll swap mine out for the stock one's.

bluemonster1

LIFE MEMBER ONLY ONCE!!!

slip your rivet thru the hole in the weight,on the exposed side sticking out..slide a washer over it and let it slide down.Then hammer the rivet end and flatten it and the washer is seated between that and the weight.Warning..sometimes when you start to hit the rivet ,the washer will jump off..be ready for it until you can flatten enough that washer can't leap out.Best is to hit the rivet on the edge all around first and then washer can't jump out then proceed normally by hammering the top of rivet.If you find sometimes you have to my rivet weight in the arms,you can take it to your drill press and drill in the center of the rivet and remove a small amount of material right thru and then weigh it..if you need more off,go to next size bt.But start off with a 1/16" bit first and go up.

HAVE FUN catching them washers when they fly off..lol

HAVE FUN catching them washers when they fly off..lol

Devilin AblueDress!

New member

If old clutch worked/shifted out fine, couldnt you have gotten an empty clutch, or taken the MM weights/springs out and put yours out of old clutch in the new one? Have you checked what original clutch was set up at? Good place to start from.

yes that's what i am doing is using the stock 8dn weights from the bad clutch and putting them in the good mm clutch. i guess my main question was could i add some weight to the 8dg weights to get close to the stock 8 dn weights because i like the profile of the dg weight better and was curious if anyone out there had maybe done something like this. so to make it easy i'll do a quick swap and have an extra set of weights laying around for back-up maybe.

Devilin AblueDress!

New member

Anything is possible. Just seems like the info on this thread is kind of all over the place, like the question being asked has changed a few times as more info comes out. In your first post you stated you already ordered new springs/helix/weights. Now your gonna have 8dg,8dn (old and new ones) 3 differnt sets of helixs, 3 different primary springs, 2 different secondary springs....for quick changing back ups? When you ask all over the place questions with info left out your gonna get all over the place answers with info left out as well.

i thought that was what this forum was for , to ask and exchange ideas and info . i'm sorry if i have more than just one question to ask and yes the original idea or question did eventually get answered by bluemonster 1 and i said thank you to him . thanks but no thanks i'll do just fine without your negative comments.

Last edited:

staggs65

Moderator

this forum is for asking questions and exchanging ideas. You're fine Kyle, ask away.

thanks staggs65 and i am very greatful for this website. has saved tons of time when it comes to problems with the blue beast. thanks again.

bluemonster1

LIFE MEMBER ONLY ONCE!!!

did you get a chance to assemble your clutch and go for a ride??If and when you do,let us know what your rpm's are at...then we will know whether or not to have to add or subtract or move around weight in the arms.

not yet had to work late today so tomorrow, saturday will be the test and tune day. we finally got some snow to ride on and temp in 28 to 31 degree range. wish it was colder but i'll take it over 45 and sunny. yes hopefully i should be able to update tomorrow night with good results.

bluemonster1

LIFE MEMBER ONLY ONCE!!!

kyle..here is the set up I went with today and am almost spot on.

8DN-20'S

4.9 grams inner hole (4.5 rivet and .4g washer)

5.6 grams outer hole (4.5 rivit and 2-.4g washers and 1-.2g washer)

TOTAL ARM WEIGHT---->53.8 grams

w-w-w primary spring

47 helix

Red Spring wrapped at 80.

I am now not over reving today.WOT at about 100mph on speedo my rpm's are at 8350-8400.I just need to grind just a tad off outer rivets to get to sweet spot..but she hauls the goods.

When the temps get warmer like to near 0 C..I will switch over to my 51/43 helix as it seems to keeps rpms down on the warm days.

Good Luck!!!

8DN-20'S

4.9 grams inner hole (4.5 rivet and .4g washer)

5.6 grams outer hole (4.5 rivit and 2-.4g washers and 1-.2g washer)

TOTAL ARM WEIGHT---->53.8 grams

w-w-w primary spring

47 helix

Red Spring wrapped at 80.

I am now not over reving today.WOT at about 100mph on speedo my rpm's are at 8350-8400.I just need to grind just a tad off outer rivets to get to sweet spot..but she hauls the goods.

When the temps get warmer like to near 0 C..I will switch over to my 51/43 helix as it seems to keeps rpms down on the warm days.

Good Luck!!!

Pauljones

New member

Blue, that set-up above must have lower gearing then stock, or you have an incredibly strong engine.

bluemonster1

LIFE MEMBER ONLY ONCE!!!

actually Paul I had smaller upper sprocket on this season,but changed it back to stock a few days ago.Strange things eh..motor now seems to have picked up a bunch of extra power..just like that about a week ago.Three weeks back I had 53.2 grams total and was having trouble to pull that.Maybe after 2500 miles my rings finally sealed.I am interested to check the compression to see what I get..and even the sled starts much easier now also...go figure...

staggs65

Moderator

I want some of that horsepower in a can youre using