yamyrider

Active member

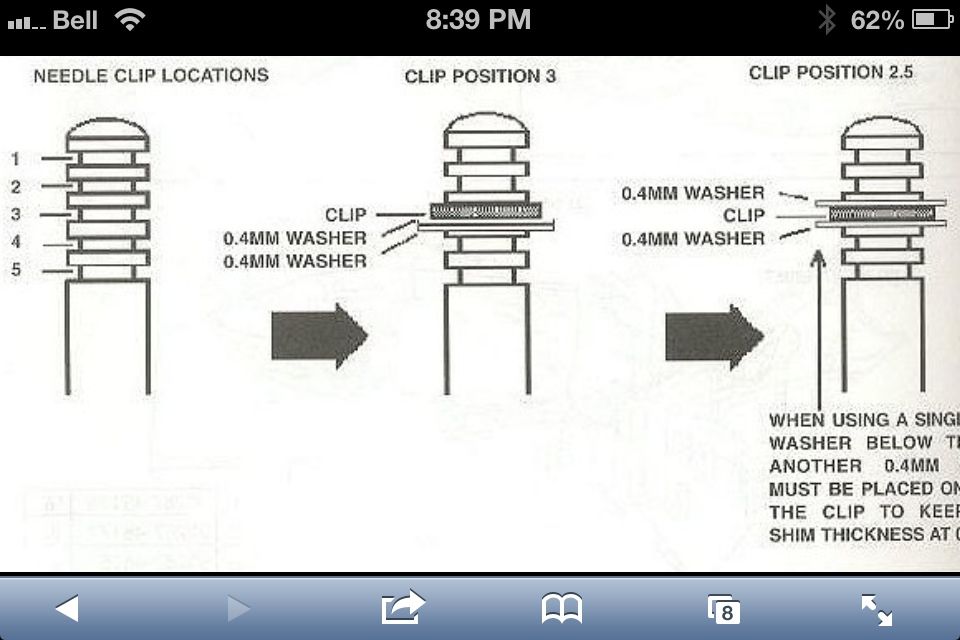

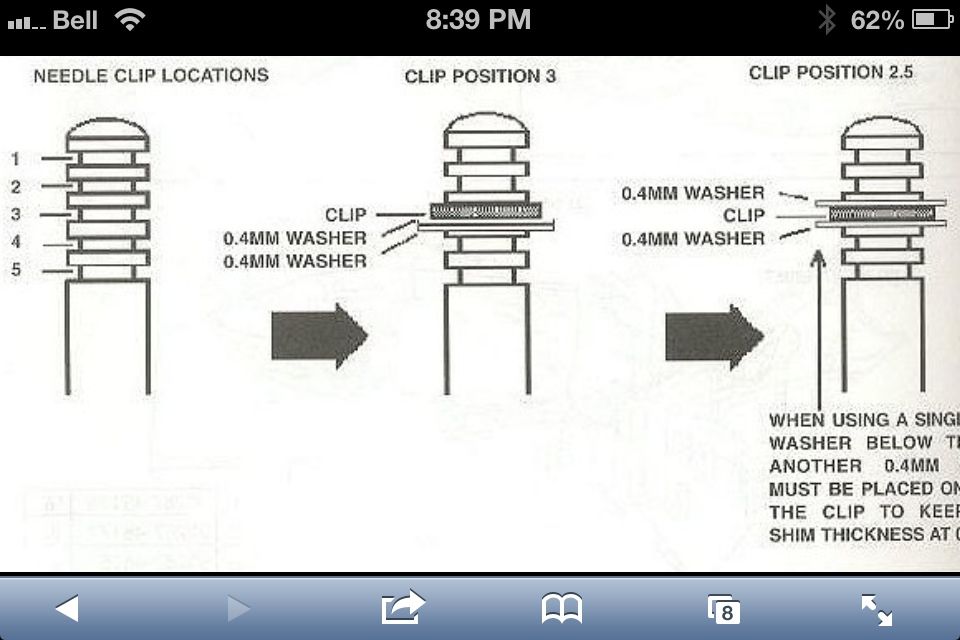

the clips on the needles are in position 3 with both washers under the clip.

I am assuming this is position 3.

To raise the needles do I put clip in 4 and put one washer under and one on top to make that 3.5

Want to make it safe of the kaboom

I am assuming this is position 3.

To raise the needles do I put clip in 4 and put one washer under and one on top to make that 3.5

Want to make it safe of the kaboom

yamyrider

Active member

3.5 is needle groove #4 with 1 shim on top, 1 on bottom of clip

roughly 3.25 fine tuning is 4th on needle but both shims on top of clip, richer then stock

stock 3.0 is 3rd groove down with both shims under clip.

Above posted by Mr Viper in another thread.

I should have looked a little harder.

roughly 3.25 fine tuning is 4th on needle but both shims on top of clip, richer then stock

stock 3.0 is 3rd groove down with both shims under clip.

Above posted by Mr Viper in another thread.

I should have looked a little harder.

srxguy

Member

I just put mine at 3.5 after my wife melted a piston

yamyrider

Active member

im gonna try 3.25 with rear heat exchanger and opticool gasket. Hopfully it wont melt

Suprx125

New member

I'd run at least 3.5, better safe than sorry.

3.25..... setting good for all around riding, if your a guy who rides fairly hard or at least gets on and off the gas a fair amount this will be good and yield off the ruined mag and center cylinder problems in the viper with good premium fuel.

3.5 setting... This is the set up for the slower riders, if you have a wife or kids who ride a viper this is the safe set up. They tend to hold the trottle in the needle section for longer periods of time to run 45-55mph on roads,railroad beds,etc, this where most of the damage always occurs the vipers are way lean right in that area, this 3.5 setting will help cool off the pistons. Still would use premium fuel no matter what.

I use octane boost even in a bone stock sled these days, you have no idea what your getting from that pump, its junk gas no way around it. So to keep your 2 stroke safe, raise the needles in them vipers and add some booster. No problems to report since doing so in likely more then 75 vipers I have done here... it works! No return burndowns is a good thing!

junk gas no way around it. So to keep your 2 stroke safe, raise the needles in them vipers and add some booster. No problems to report since doing so in likely more then 75 vipers I have done here... it works! No return burndowns is a good thing!

Just to reitterate the settings:

3.25 setting- 4th groove down from top of needle(non tapered part), both plastic shims on TOP of the clip

3.5 setting- 4th groove down on the needle, 1 plastic shim on TOP of the clip, and 1 plastic shim UNDER the clip, raising the needle up in the slide by the 1 plastic shim.

3.5 setting... This is the set up for the slower riders, if you have a wife or kids who ride a viper this is the safe set up. They tend to hold the trottle in the needle section for longer periods of time to run 45-55mph on roads,railroad beds,etc, this where most of the damage always occurs the vipers are way lean right in that area, this 3.5 setting will help cool off the pistons. Still would use premium fuel no matter what.

I use octane boost even in a bone stock sled these days, you have no idea what your getting from that pump, its

junk gas no way around it. So to keep your 2 stroke safe, raise the needles in them vipers and add some booster. No problems to report since doing so in likely more then 75 vipers I have done here... it works! No return burndowns is a good thing!

junk gas no way around it. So to keep your 2 stroke safe, raise the needles in them vipers and add some booster. No problems to report since doing so in likely more then 75 vipers I have done here... it works! No return burndowns is a good thing!

Just to reitterate the settings:

3.25 setting- 4th groove down from top of needle(non tapered part), both plastic shims on TOP of the clip

3.5 setting- 4th groove down on the needle, 1 plastic shim on TOP of the clip, and 1 plastic shim UNDER the clip, raising the needle up in the slide by the 1 plastic shim.

mrviper700 said:3.25..... setting good for all around riding, if your a guy who rides fairly hard or at least gets on and off the gas a fair amount this will be good and yield off the ruined mag and center cylinder problems in the viper with good premium fuel.

3.5 setting... This is the set up for the slower riders, if you have a wife or kids who ride a viper this is the safe set up. They tend to hold the trottle in the needle section for longer periods of time to run 45-55mph on roads,railroad beds,etc, this where most of the damage always occurs the vipers are way lean right in that area, this 3.5 setting will help cool off the pistons. Still would use premium fuel no matter what.

I use octane boost even in a bone stock sled these days, you have no idea what your getting from that pump, itsjunk gas no way around it. So to keep your 2 stroke safe, raise the needles in them vipers and add some booster. No problems to report since doing so in likely more then 75 vipers I have done here... it works! No return burndowns is a good thing!

Just to reitterate the settings:

3.25 setting- 4th groove down from top of needle(non tapered part), both plastic shims on TOP of the clip

3.5 setting- 4th groove down on the needle, 1 plastic shim on TOP of the clip, and 1 plastic shim UNDER the clip, raising the needle up in the slide by the 1 plastic shim.

Awesome, very descriptive.

But why does it need to be in the 4th groove from the top

To be at a 3.25 or 3.5 setting? Wouldn't it be te 3rd groove?

I'm no expert on carbs... Just would like to know, cuz I don't want to screw anything up

3rd groove is the 3 spot. Anything higher (3.25, 3.5) requires going to the 4 spot. If you wanted less you could stay at 3 and then move the washer to over/under (2.5) or both over (2.25).

Clear as mud right?

Clear as mud right?

Mysledblows said:3rd groove is the 3 spot. Anything higher (3.25, 3.5) requires going to the 4 spot. If you wanted less you could stay at 3 and then move the washer to over/under (2.5) or both over (2.25).

Clear as mud right?

lol dont know how clear mud is but...

ya that makes sense, ill put them at 3.25

thanks!

bADa$$ SRX

New member

totally lost on this, so your saying 4th groove is essentially 3.25 and then the shims are .25 each so 4th groove and one shim underneath would be 3.25+.25=3.5? and then 4th groove with 2 shims underneath would be 3.25+.25+.25=3.75 correct? or am i just a lost cause? lolmrviper700 said:3.25..... setting good for all around riding, if your a guy who rides fairly hard or at least gets on and off the gas a fair amount this will be good and yield off the ruined mag and center cylinder problems in the viper with good premium fuel.

3.5 setting... This is the set up for the slower riders, if you have a wife or kids who ride a viper this is the safe set up. They tend to hold the trottle in the needle section for longer periods of time to run 45-55mph on roads,railroad beds,etc, this where most of the damage always occurs the vipers are way lean right in that area, this 3.5 setting will help cool off the pistons. Still would use premium fuel no matter what.

I use octane boost even in a bone stock sled these days, you have no idea what your getting from that pump, itsjunk gas no way around it. So to keep your 2 stroke safe, raise the needles in them vipers and add some booster. No problems to report since doing so in likely more then 75 vipers I have done here... it works! No return burndowns is a good thing!

Just to reitterate the settings:

3.25 setting- 4th groove down from top of needle(non tapered part), both plastic shims on TOP of the clip

3.5 setting- 4th groove down on the needle, 1 plastic shim on TOP of the clip, and 1 plastic shim UNDER the clip, raising the needle up in the slide by the 1 plastic shim.

what you have to remember is the groove number is only that exact groove number setting IF BOTH of the plastic washers are UNDER the clip raising the needle up in the slide.

so, if you want number 2, its the 2nd groove down but both shims have to be UNDER the cip to be a true number 2 setting. If you place the clip in groove 2 but only use 1 of the shims under the clip youd drop it back to 1.5, because you only used 1 shim under the clip, hope that makes you understand ghow it works.

so, if you want number 2, its the 2nd groove down but both shims have to be UNDER the cip to be a true number 2 setting. If you place the clip in groove 2 but only use 1 of the shims under the clip youd drop it back to 1.5, because you only used 1 shim under the clip, hope that makes you understand ghow it works.

bADa$$ SRX

New member

ok its alot more clearer now mr viper, thanks lolmrviper700 said:what you have to remember is the groove number is only that exact groove number setting IF BOTH of the plastic washers are UNDER the clip raising the needle up in the slide.

so, if you want number 2, its the 2nd groove down but both shims have to be UNDER the cip to be a true number 2 setting. If you place the clip in groove 2 but only use 1 of the shims under the clip youd drop it back to 1.5, because you only used 1 shim under the clip, hope that makes you understand ghow it works.

bADa$$ SRX said:totally lost on this, so your saying 4th groove is essentially 3.25 and then the shims are .25 each so 4th groove and one shim underneath would be 3.25+.25=3.5? and then 4th groove with 2 shims underneath would be 3.25+.25+.25=3.75 correct? or am i just a lost cause? lol

Now im confused

Now I'm so comfused about the needle settings

This is from the tech section

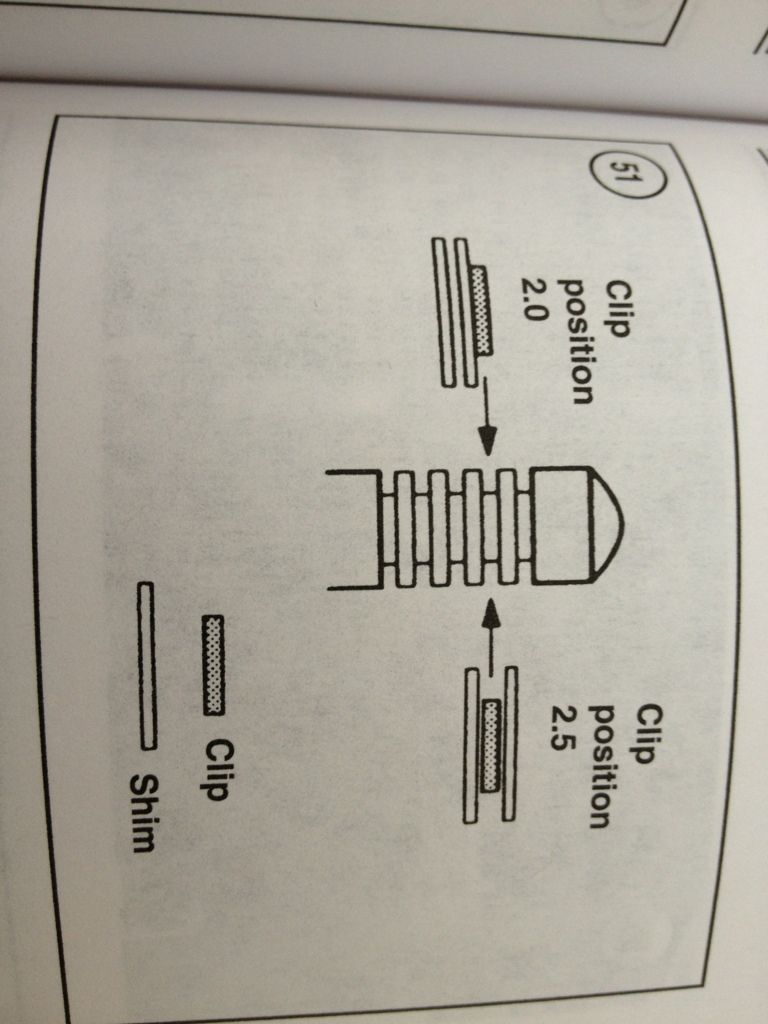

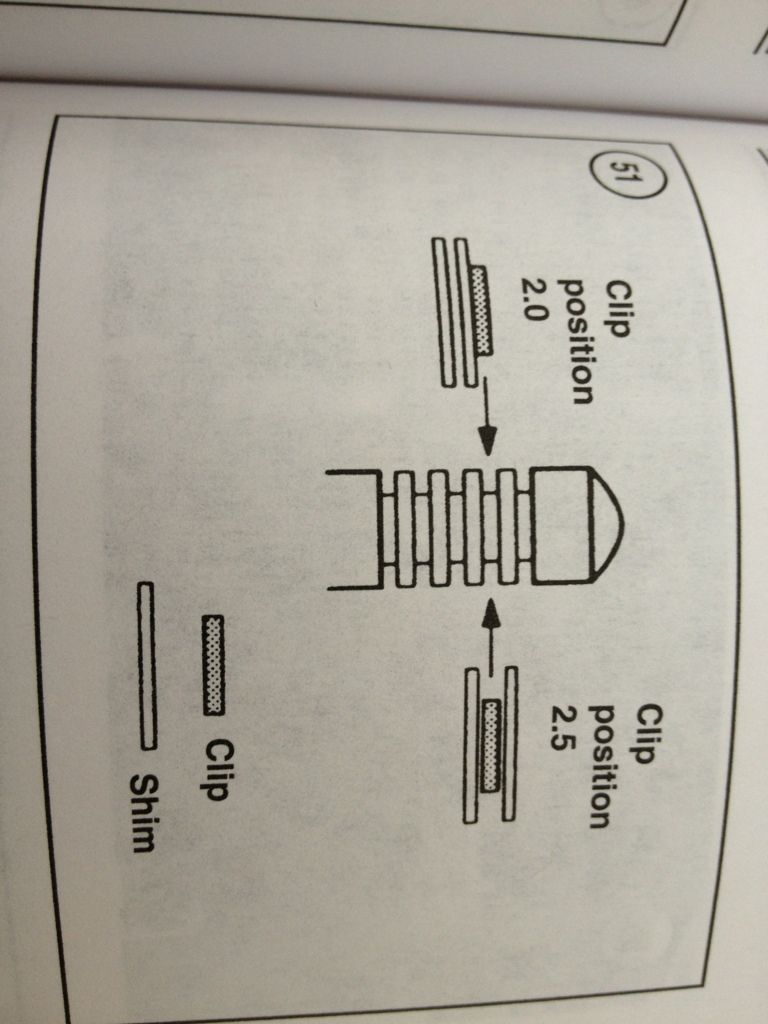

And this is in my clymer manual

They are basically saying the opposite of each other

Can u help me out on this mrviper? I would like to put them at 3.25

This is from the tech section

And this is in my clymer manual

They are basically saying the opposite of each other

Can u help me out on this mrviper? I would like to put them at 3.25

Last edited:

obviously the clymer manual is flat out wrong.

I listed it as clear as i could in this thread, its listed there where to place the shims and the clip.

I listed it as clear as i could in this thread, its listed there where to place the shims and the clip.

mrviper700 said:obviously the clymer manual is flat out wrong.

I listed it as clear as i could in this thread, its listed there where to place the shims and the clip.

X2. Just look at the Clymer manual pictures. They have it correct on the left side of the page with the clip in position 2 and both washers underneath. If you remove one of those washers and place on top, you are lowering the needle since it will sit further down in the carb. So they are clearly wrong in stating it is position 2.5, should be stating it is 1.5.

mrviper700 said:obviously the clymer manual is flat out wrong.

I listed it as clear as i could in this thread, its listed there where to place the shims and the clip.

You are right,

After taking it it apart and looking at the needles it all makes sense to me.

It's just with with so much different information just confused the heck out of me

Thanks so much for clearing things up.

Next time I should take things apart and understand them better