I have a 1997 Venture 600 twin that lost the mag side piston last week when the skirt broke. I tore the engine down and inspected the crank and all seemed fine.

I replaced both pistons. I spoke to some sledheads at work and they told me the sled was lean as there was no piston wash but I always heard these sleds were pig rich.

I increased the main jet from 160 to 170 and raised the needle 1/2 a notch.

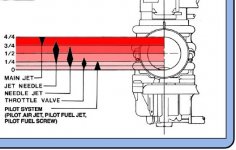

Low end and mid range are perfect, 3/4 throttle and above is dirty- wont rev up right and runs like crap. Mid range sled runs great sled will do 70 mph at 3/4 throttle.

When I did the engine rebuild I did pull the carbs and cleaned the heck out of them.

My understanding is that 3/4 throttle and above is all the main jet. Should I return them to the stock 160?

I replaced both pistons. I spoke to some sledheads at work and they told me the sled was lean as there was no piston wash but I always heard these sleds were pig rich.

I increased the main jet from 160 to 170 and raised the needle 1/2 a notch.

Low end and mid range are perfect, 3/4 throttle and above is dirty- wont rev up right and runs like crap. Mid range sled runs great sled will do 70 mph at 3/4 throttle.

When I did the engine rebuild I did pull the carbs and cleaned the heck out of them.

My understanding is that 3/4 throttle and above is all the main jet. Should I return them to the stock 160?

I will also add that this sled was known for bad factory pistons so I believe that was the reason for the broken skirt. The sled only has 2,000 miles on it.

I changed the mains back to stock. No change.

Can anyone comment as to the piston wash?

A couple of bucks

VIP Member

drew24

New member

How did the crank seals look?

The crank seals looked good.

I put about 150 miles on this since rebuilding it last week, here's what I noticed:

No change in performance with the original 160 main jets vs the 170 main jets. I re-installed the 170's.

Anything over 3/4 throttle results in a drop in RPM and it will not build back up.

Performance is great anywhere below 3/4 throttle.

I can build to 7,000 rpms eventually, if I go full throttle it will drop, and eventually settle at 6,000 rpms.

Any advice would be really appriciated guys. I will say that, my fuel mpg went from 7 mpg to 10 mpg after the rebuild even with the larger main and the increase in needle jet height.

I put about 150 miles on this since rebuilding it last week, here's what I noticed:

No change in performance with the original 160 main jets vs the 170 main jets. I re-installed the 170's.

Anything over 3/4 throttle results in a drop in RPM and it will not build back up.

Performance is great anywhere below 3/4 throttle.

I can build to 7,000 rpms eventually, if I go full throttle it will drop, and eventually settle at 6,000 rpms.

Any advice would be really appriciated guys. I will say that, my fuel mpg went from 7 mpg to 10 mpg after the rebuild even with the larger main and the increase in needle jet height.

A couple of bucks

VIP Member

Just spitballing here......if the top of your air box comes off, see if running w/o it changes anything. There is nothing blocking up the exhaust?

Good idea- but no change (tried it out a couple days back during tuning). The exhaust seems clear, when I did the rebuild I shook it out and nothing was loose.

I need to throw this out there as I failed to do so earlier- when I did the rebuild I installed a thinner head gasket (took 3 layers out leaving 2) and did the reed notch. I thought I had stated this, not sure if any of it makes a difference as to this problem.

I need to throw this out there as I failed to do so earlier- when I did the rebuild I installed a thinner head gasket (took 3 layers out leaving 2) and did the reed notch. I thought I had stated this, not sure if any of it makes a difference as to this problem.

A couple of bucks

VIP Member

Blip the choke up around 6-7000.

I will do that and report back. Are you thinking that with the head gasket mod and reed notch it is lean at WOT?

A couple of bucks

VIP Member

drew24

New member

How does the float adjustment look? When was the fuel filter last changed?

I'm not sure what to look for in float adjustment to be honest. I know before the rebuild I never had this issue.

I pulled the carbs off again for another look. I found nothing abnormal, and they are spotless.

One thing that I did realize, is that the impluse line going to the fuel pump was replaced at time of engine rebuild. I used standard blue fuel line. I have replaced it with rubber hose. I dont think this was a problem but maybe it was collapsing during high RPM.

One thing that I did realize, is that the impluse line going to the fuel pump was replaced at time of engine rebuild. I used standard blue fuel line. I have replaced it with rubber hose. I dont think this was a problem but maybe it was collapsing during high RPM.

A couple of bucks

VIP Member

The reason he mentioned float adjustment is that it sounds like it might be starving above 3/4 throttle.

drew24

New member

Did you get the motor properly aligned with the proper specs for clutch distance and offset. Possible it is a binding problem. I'm also just throwing stuff out there as I think of it.

Before I pulled the motor I made alignment marks on all 4 motor mounts, when reinstalling I matched them up. Not perfect but it has to be very, very close.

I did check the floats in the carbs, very limited range of movement. I tweaked the tabs a bit allowing the needles to drop more, I am leary of fuel seeping by but so far so good.

I also replaced the impluse line with a hard rubber that can't collapse.

Sled is warming up now and I will report back in a few minutes.

I did check the floats in the carbs, very limited range of movement. I tweaked the tabs a bit allowing the needles to drop more, I am leary of fuel seeping by but so far so good.

I also replaced the impluse line with a hard rubber that can't collapse.

Sled is warming up now and I will report back in a few minutes.

ls No change. Sled falls on it's face if you go wide open at anypoint- from idle, from a cruise speed, or from 3/4 throttle.

This has smart carbs, I think I am going to disconnect some of the sensors and see what happens- unless someone thinks that's a bad idea.

This has smart carbs, I think I am going to disconnect some of the sensors and see what happens- unless someone thinks that's a bad idea.

A couple of bucks

VIP Member

Make sure the rubber impulse line you used is reinforced w/ ply. If not, it could collapse under load. I usually use the Dayco stuff because that's readily available.