Schocker65

New member

So I went back to the settings/components per the tech page, but with new springs in both clutches, all new rollers and bushings on the primary (no lube anywhere), cleaned shaft and bushings on secondary (left dry), with small amount of grease on secondary helix.

Far worse now than it was. WTF. It actually was much better before with the 8AB weights. Backshifting is terrible now, as it was before I started working on it. Let off the gas from a cruise and it almost needs full throttle to begin accelerating again. Engine HATES this setup. Lots more spitting and sputtering in the midrange. Just awful. I forgot how bad it was before I started working on it.

Am I wrong to leave the bushings/shaft on the secondary dry? I'm wondering if I go back to the 8AB's maybe I can improve things by messing with the spring setting? Before I throw in the towel on this thing, I'll be verifying alignment, motor mount integrity and try a good abrasive cleaning of the clutch faces and scuffing the belt itself.

I'm just flailing at this point. I hate not being able to figure it out.

Far worse now than it was. WTF. It actually was much better before with the 8AB weights. Backshifting is terrible now, as it was before I started working on it. Let off the gas from a cruise and it almost needs full throttle to begin accelerating again. Engine HATES this setup. Lots more spitting and sputtering in the midrange. Just awful. I forgot how bad it was before I started working on it.

Am I wrong to leave the bushings/shaft on the secondary dry? I'm wondering if I go back to the 8AB's maybe I can improve things by messing with the spring setting? Before I throw in the towel on this thing, I'll be verifying alignment, motor mount integrity and try a good abrasive cleaning of the clutch faces and scuffing the belt itself.

I'm just flailing at this point. I hate not being able to figure it out.

LIT-12468-00-99

Undo the grease on the helix. Both clutches should be dry... except... grease the jackshaft splines a little so the secondary slides back and forth smoothly, and it allows easier removal down the road. Clean the rust and gunk off of the jackshaft and ID of the secondary spline hub first though. With the bolt and spacers installed, the secondary should slide back and forth on the jackshaft about 1/16" give or take, seems most I've seen are a bit more than that.

Are you certain that the secondary spring is twisted properly? Without a belt on the sled, you should be able to twist and push the helix (like when removing the belt) and feel the spring tension when doing so, and it should then snap back into position when you let go.

Undo the grease on the helix. Both clutches should be dry... except... grease the jackshaft splines a little so the secondary slides back and forth smoothly, and it allows easier removal down the road. Clean the rust and gunk off of the jackshaft and ID of the secondary spline hub first though. With the bolt and spacers installed, the secondary should slide back and forth on the jackshaft about 1/16" give or take, seems most I've seen are a bit more than that.

Are you certain that the secondary spring is twisted properly? Without a belt on the sled, you should be able to twist and push the helix (like when removing the belt) and feel the spring tension when doing so, and it should then snap back into position when you let go.

Schocker65

New member

I assume I have it twisted correctly; I was careful to note how it came out. It is definitely preloaded.

I have read varying opinions on whether to lube the helix, but the primary reason not to is to avoid belt dust collection, right? I'm assuming the grease being there would not be negatively impacting performance right away.

I did not grease the splines - I will go ahead and do that, though it does seem to move freely through its play, which seems like 1-2 mm, which I believe to be correct.

With those 8CR's, BTW, the RPM's at WOT are still 8000-8100, and weren't coming down. Honestly, I was not happy with the performance of the sled with the 8AB's in it, but it was really much better than with the 8CR's.

I will be putting the 8AB's back in and maybe reducing the helix twist to 40 degrees to see what that does. That would leave me with just a 43 degree helix vs. 45 degree as called out in my service manual.

One thing is for sure - my sled, with me on it, does not like the setup detailed on the tech pages. I still could have some other as yet undiagnosed problem going on, but I think I'll try the above combo to see if I can creep up on something more rideable.

I have read varying opinions on whether to lube the helix, but the primary reason not to is to avoid belt dust collection, right? I'm assuming the grease being there would not be negatively impacting performance right away.

I did not grease the splines - I will go ahead and do that, though it does seem to move freely through its play, which seems like 1-2 mm, which I believe to be correct.

With those 8CR's, BTW, the RPM's at WOT are still 8000-8100, and weren't coming down. Honestly, I was not happy with the performance of the sled with the 8AB's in it, but it was really much better than with the 8CR's.

I will be putting the 8AB's back in and maybe reducing the helix twist to 40 degrees to see what that does. That would leave me with just a 43 degree helix vs. 45 degree as called out in my service manual.

One thing is for sure - my sled, with me on it, does not like the setup detailed on the tech pages. I still could have some other as yet undiagnosed problem going on, but I think I'll try the above combo to see if I can creep up on something more rideable.

Grease on the clutches will collect belt dust and dirt, even year round. Your 12 month sled care program may be ideal to keep it clean, but every year I see more of these sleds with pigsty engine bays from much more than just the belt and 2stroke oil. Grease can also get slung around at higher rpms depending on how much is applied, or if it is squeezed out during operation. Could end up on the sheaves/belt. I'm sure lube has been used on clutches many times to try to "tune out" issues (yours doesn't sound like that based on all the work you've done), but the opinion that I'd go with is Yamaha's.

Not sure if this has any bearing, but in your pic is an 89L belt, the original spec is 8CJ. I don't know how these compare, but it's not uncommon for a different belt to require changes in clutch tuning. Maybe someone here knows the difference between them, or how an 89L belt would typically act in place of the 8CJ.

It certainly seems that if the clutches are in good operating condition, and with all of the factory spec parts installed, that the sled would perform like normal or very close to it. Unless it's the belt or something else out of whack. Something else that you can try is to see if there are any user clutching/tuning setups for a 500 twin similar to yours in the Tech Pages here. There won't be as much data as the 700cc sleds, but you may find something that helps. Always keep track of any changes you make and how the sled runs with those changes. If nothing else, you can change rivet weight in either or both of your 8AB's or 8CR's to bring your 8100rpms down. Also, as you mentioned above, can try different secondary spring settings to see how the sled reacts, that's quick and easy.

Are you certain the engine is running properly, good clean carbs, jetted & adjusted properly, good compression, good spark? You had mentioned spitting/sputtering, these engines might have a little bit of that in the low-mid range - it's been awhile since I've put any miles on a twin, maybe it's more like a burble, but it shouldn't effect drivability.

Not sure if this has any bearing, but in your pic is an 89L belt, the original spec is 8CJ. I don't know how these compare, but it's not uncommon for a different belt to require changes in clutch tuning. Maybe someone here knows the difference between them, or how an 89L belt would typically act in place of the 8CJ.

It certainly seems that if the clutches are in good operating condition, and with all of the factory spec parts installed, that the sled would perform like normal or very close to it. Unless it's the belt or something else out of whack. Something else that you can try is to see if there are any user clutching/tuning setups for a 500 twin similar to yours in the Tech Pages here. There won't be as much data as the 700cc sleds, but you may find something that helps. Always keep track of any changes you make and how the sled runs with those changes. If nothing else, you can change rivet weight in either or both of your 8AB's or 8CR's to bring your 8100rpms down. Also, as you mentioned above, can try different secondary spring settings to see how the sled reacts, that's quick and easy.

Are you certain the engine is running properly, good clean carbs, jetted & adjusted properly, good compression, good spark? You had mentioned spitting/sputtering, these engines might have a little bit of that in the low-mid range - it's been awhile since I've put any miles on a twin, maybe it's more like a burble, but it shouldn't effect drivability.

Schocker65

New member

Great response - thank you. I went with the 89L belt as it looks to be the replacement for the 8CJ which seems to be unavailable.

Carbs are stock jets and I've cleaned them thoroughly, and replaced pilot screw o-rings, needle valves, etc. Compression test is 115 both sides. Starts easily. It does have V-Force reeds which looked good when I had it apart.

I'm anticipating that the poor engine performance will stop when I go back to the 8AB's. If not, I will check my plug caps, as I had them off to check plug appearance in between clutch changes.

Thank you again for sharing your experience. I really appreciate it. I'll keep you posted.

Carbs are stock jets and I've cleaned them thoroughly, and replaced pilot screw o-rings, needle valves, etc. Compression test is 115 both sides. Starts easily. It does have V-Force reeds which looked good when I had it apart.

I'm anticipating that the poor engine performance will stop when I go back to the 8AB's. If not, I will check my plug caps, as I had them off to check plug appearance in between clutch changes.

Thank you again for sharing your experience. I really appreciate it. I'll keep you posted.

FredrikMoström

New member

Nice sled����

Schocker65

New member

Conditions heavy and warm today; similar behavior with the revised helix setting and the 8AB's. revs were at 7800-7900. Better, but perhaps conditions related.

Still running like crap unless squeezed hard. Thought I might have plug cap problems; even saw some sooty looking stuff under the caps. Replaced them and put in new plugs. No difference.

I'm starting to lose hope. Very discouraged.

Still running like crap unless squeezed hard. Thought I might have plug cap problems; even saw some sooty looking stuff under the caps. Replaced them and put in new plugs. No difference.

I'm starting to lose hope. Very discouraged.

Schocker65

New member

Still playing around with this V-Max 500 - just cleaned the carbs again and re-synced them (eccentric adjuster nut/screw on left carb had come loose late last year and I had eyeballed the synchronization from the top of the slides at that time). Synced this time by even-ing up the bottom of the slides to the top of the carb throats.

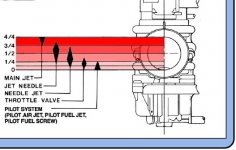

Also set the pilot screws 2-1/4 turns out instead of 1-3/4 turns out. I recall that when I originally had cleaned the carbs in advance of the first season that I had it, the pilot screws were more than three turns out. Wondering if it's possible that the pilot screw adjustment is meant to be more turns out with the V-force reeds? Had I made it run worse by returning to the stock 1-3/4 turns?

End result is just a minor improvement from what was happening last year. Still a dead zone in the 35-50 MPH cruise range - nothing seems to happen when I add throttle until I get to about 3/4 full throttle, and then it takes off like a scalded cat.

Also - experienced the odd stuck brakes sensation again. Let off the gas and it slowed as if the brake was on - this only happened once today, but I am baffled by it. I carefully serviced the brakes last season in an attempt to eliminate this, but it still has reared its head. I also replaced all three rear idlers last year, so they are new.

I've read much about how these 500's use lots of gas - it's very easy to understand if what I am experiencing is anything close to normal for these sleds - much heavier throttle inputs and higher revs needed for just routine riding compared to my other sleds ('99 MXZ 440 and '03 Viper).

Also set the pilot screws 2-1/4 turns out instead of 1-3/4 turns out. I recall that when I originally had cleaned the carbs in advance of the first season that I had it, the pilot screws were more than three turns out. Wondering if it's possible that the pilot screw adjustment is meant to be more turns out with the V-force reeds? Had I made it run worse by returning to the stock 1-3/4 turns?

End result is just a minor improvement from what was happening last year. Still a dead zone in the 35-50 MPH cruise range - nothing seems to happen when I add throttle until I get to about 3/4 full throttle, and then it takes off like a scalded cat.

Also - experienced the odd stuck brakes sensation again. Let off the gas and it slowed as if the brake was on - this only happened once today, but I am baffled by it. I carefully serviced the brakes last season in an attempt to eliminate this, but it still has reared its head. I also replaced all three rear idlers last year, so they are new.

I've read much about how these 500's use lots of gas - it's very easy to understand if what I am experiencing is anything close to normal for these sleds - much heavier throttle inputs and higher revs needed for just routine riding compared to my other sleds ('99 MXZ 440 and '03 Viper).

A couple of bucks

VIP Member

Schocker65

New member

Went for a ride on the V-Max today - only 9F at the time. Got more miles in this time with more varied conditions than I've previously been able to - sled performed better than I thought it would. I might be a little rich at higher temps based on what I experienced today. I am still experiencing an intermittent drag issue of some sort - either sticking brake or perhaps bearing somewhere intermittently binding up. Can definitely feel it coming and going once in a while. When it's happening, the sled will slow to a stop as if I'm giving a light squeeze on the brake. No weird noises that I can notice - the brake also doesn't seem to be getting overheated. I'm thinking if it were a driveshaft bearing, I would either be hearing it or feeling it. Maybe I'll spit an idler wheel out the side some day and my problem will be gone!

Did you check your brake pads? How about the brake disk? I guess you haven't seen a dyno test for this sled, not much happens before half throttle at least. I put tempaflow and reeds from a viper, and now I have to re-clutch due to the increase in power.

Schocker65

New member

Pads and rotor are good - I replaced many brake parts last year and carefully re-assembled with cleanup and lube in the right places (sliding surfaces).

I will keep an eye/ear on things and look for anything else that might be causing the drag. From a clutching/engine standpoint, just coming to the conclusion that this is a very high strung drivetrain that needs a lot of revs to get things done. It really does rip when you ask for it, at least for a 500. After all that, I have to say that I really enjoyed my ride on it yesterday, and my 14 year old son enjoyed it today while I rode my Viper. It was 10 degrees when we set out; 5 degrees when we got home. BRRRRR

I will keep an eye/ear on things and look for anything else that might be causing the drag. From a clutching/engine standpoint, just coming to the conclusion that this is a very high strung drivetrain that needs a lot of revs to get things done. It really does rip when you ask for it, at least for a 500. After all that, I have to say that I really enjoyed my ride on it yesterday, and my 14 year old son enjoyed it today while I rode my Viper. It was 10 degrees when we set out; 5 degrees when we got home. BRRRRR

You could try gearing it down 1 tooth.

it could be the track tension is too tight on it. i have also heard of a bad clip causing drag. i know the origonal ripsaws clipped every 3rd where horrible for this as i fought with the one i had on my 01 sx500r as it would burn the belt on accel as well.

Schocker65

New member

Thanks for the input, guys.

Gearing down a tooth might address some of the concerns that I have. The intermittent drag thing is another matter, of course. My track tension is pretty loose - I had loosened it last season in hopes of freeing things up. It actually did help a bit; actually it eliminated a bit of a ratcheting that I had at take off previously. It now hangs quite a bit looser than what the manual calls for. The track itself is a Kimpex Ultimate Traxxion I believe? It is in fair shape, but does seem to be a bit of a stiff roller.

The weather has been so freaking cold here that I have not been willing to go out in the garage to look at anything else. I will keep an eye on things and look for any other signs of binding bearings, etc.

Gearing down a tooth might address some of the concerns that I have. The intermittent drag thing is another matter, of course. My track tension is pretty loose - I had loosened it last season in hopes of freeing things up. It actually did help a bit; actually it eliminated a bit of a ratcheting that I had at take off previously. It now hangs quite a bit looser than what the manual calls for. The track itself is a Kimpex Ultimate Traxxion I believe? It is in fair shape, but does seem to be a bit of a stiff roller.

The weather has been so freaking cold here that I have not been willing to go out in the garage to look at anything else. I will keep an eye on things and look for any other signs of binding bearings, etc.

A couple of bucks

VIP Member

Kind of a ...... fluttering type of drag? Like something is sloppy and flopping/fluttering around. Does it decrease with engine speed or decrease w/ sled speed?

Schocker65

New member

Not fluttering. Feels just like brake dragging, comes and goes. Causes revs to climb due to the resistance - assuming it could be anything from a jackshaft bearing to an idler wheel bearing, or the brake itself, but not seeing any heat evidence on the brake. Let off the throttle while it's happening and the sled will come to a stop as if the brake is being applied lightly. When the problem is NOT present, the sled coasts much more freely.

Maybe it doesn't have time enough to heat up.

A couple of bucks

VIP Member

Does the speedometer act up?

Schocker65

New member

Sled has been plenty warmed up when behaving like that. Speedometer is smooth. I re-packed the speedo side bearing before last "season". Winter sucked last year.

FWIW, I just ordered a couple of new 8CJ belts because I have more money than sense (that reflects VERY poorly on my sense). I know it won't do anything to the drag situation, but wondering if it will help the high revs at low speed condition. Going to first try a thorough cleaning of the clutch faces to see if that has any effect.

FWIW, I just ordered a couple of new 8CJ belts because I have more money than sense (that reflects VERY poorly on my sense). I know it won't do anything to the drag situation, but wondering if it will help the high revs at low speed condition. Going to first try a thorough cleaning of the clutch faces to see if that has any effect.