30 mm. with 10 kg. weight, that sounds awfully tight to me. Do you just use a scale and hook it to the track?

caravanman

New member

Yup.

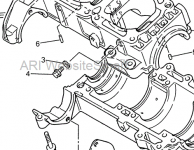

PS: I used to use the head of my Mag-lit instead of a steel ruler.

View attachment 61025

After you get the hang of it you don't even use any of these measuring tools.

Put it to just under 25 mm. with a 7 kg. weight, hope that's not too tight. It was a bit tricky to get it equal on both sides since the track wandered sideways back and forth but I think it's reasonable straight. I figured that as long as the guiding knobs never touched the slides it was ok. I'm not sure but it feels like the jerk was reduced almost to the point of vanishing but I'll have to wait for the snow to come before I can test more.

braindead1684

Member

Sounds about right I want to say we set my dads to 1" at 20lbs which sounds like you did just under an inch at 15lb.

How much did you have to turn it to get there?

How much did you have to turn it to get there?

Sounds about right I want to say we set my dads to 1" at 20lbs which sounds like you did just under an inch at 15lb.

How much did you have to turn it to get there?

I would say roughly 2 turns. Since I was missing 3 kg. I kind of eyeballed it. If I had it loaded with 7 kg. I did not need any force to speak of two get to the 30 mm mark. I could use my little finger and I know I can not lift 3 cartons of milk that way so...

Tried a bit, it's better. It didn't go away entirely but it's better. I also tried braking and there is no "delay and chunk!" so I don't believe it's the chain. Now I'm waiting for the belt I ordered.

On another not, how sensitive are these sleds to overheating? I was riding on the lake at a very sedate pace and when I stopped too look around and idled for maybe 30 seconds I noticed the temp red light. I don't know how long it's been on but I shut down immediately, waited with raised hood 10 min and rode him, no problem. I've never encountred this with this sled or the Exciter II I previously owned. It's been warm and now cold so it's like running on concrete but still... It shouldn't bee any ill effects or?

On another not, how sensitive are these sleds to overheating? I was riding on the lake at a very sedate pace and when I stopped too look around and idled for maybe 30 seconds I noticed the temp red light. I don't know how long it's been on but I shut down immediately, waited with raised hood 10 min and rode him, no problem. I've never encountred this with this sled or the Exciter II I previously owned. It's been warm and now cold so it's like running on concrete but still... It shouldn't bee any ill effects or?

Vincent

Well-known member

In those conditions ( snow is hard like concrete) an engine can easily be overheated and damage. We're experienceing the same thing around here lately. All the liquid sleds new or old have been overheating and care must be taken to avoid damage.

Last edited:

In those conditions ( snow is hard like concrete) an engine can easily be overheated and damage. We're experienceing the same thing around here lately. All the liquid sleds new or old have been overheating and care must be taken to avoid damage.

The light didn't go on, on my return trip and then engine had to work a bit harder in the forest than on the lake so maybe temp was on the limit and went on due to the short time standing there idling.

braindead1684

Member

2 turns don't really seem like that much, you may have to go a little tighter but hard to say for sure.

I have only had the light come on a couple times once the snow was deep but the thermostat broke and well no coolant flow kinda makes it hard to stay cool.

The second time was hard pack ads for 1-2 miles around 32* and it was on for a second when i drove off the side for a bit and it brought it back down.

Hard pack is really hard on these as the heat exchanges are all in the tunnel online the late 90's Vmax that have them under the running boards and will get dust from the ski's.

I have only had the light come on a couple times once the snow was deep but the thermostat broke and well no coolant flow kinda makes it hard to stay cool.

The second time was hard pack ads for 1-2 miles around 32* and it was on for a second when i drove off the side for a bit and it brought it back down.

Hard pack is really hard on these as the heat exchanges are all in the tunnel online the late 90's Vmax that have them under the running boards and will get dust from the ski's.

Maybe it's time to change the coolant after this season. I've never done it before so here is the plan: My block does not seem to have a bleeder screw so I remove the seat and a hose from the radiator in the back. Then I raise the front and let it flow out. After that I Use a garden hose to flush the system. Making sure most of the water is gone I reattach the hose. Raise the front maybe even more and put in new coolant via the filler cap. Air should come out through the expansion bottle or? Anything I missed?

braindead1684

Member

caravanman

New member

Yes the XT rear exchanger has bleeders. There is a bleeder on the T-stat housing as well.

PS:The screws in the block below the export ports are the coolant drains.

PS:The screws in the block below the export ports are the coolant drains.

Got the new drive belt today. It squealed a lot so I removed the secondary clutch and removed the washers for the three screws in the back, it got better but it still feels a bit tight. It doesn't squeal but when I hoist the back end the track turns on idle. I can stop it with one hand, barely (I'm not a strong guy) Is it supposed to be like this with a new belt?

I also disassembled the secondary and I think I did something wrong. My manual didn't mention the 600XT only Vmax 600 and 600-long (called ST in Europe) along with the 500. Since I figured the 600 short was closest to mine I put the spring at positions 1 on the inner sheave and position 3 at the "hub". It feels a lot softer though but I don't feel any big difference when riding. If it's the wrong position and the spring isn't preloaded enough does that mean it shifts out sooner?

Finally On my ET it's easy to change the belt but on the Vmax it's hell. I tried to do as in the manual (grab inner sheave, twist clockwise and push) but it wouldn't budge and it's almost impossible to get a grip on it with the belt on. Is there some trick to it? I had to do it with brute force and the belt kept getting stuck at the "hinge" for the clutch cover.

I also disassembled the secondary and I think I did something wrong. My manual didn't mention the 600XT only Vmax 600 and 600-long (called ST in Europe) along with the 500. Since I figured the 600 short was closest to mine I put the spring at positions 1 on the inner sheave and position 3 at the "hub". It feels a lot softer though but I don't feel any big difference when riding. If it's the wrong position and the spring isn't preloaded enough does that mean it shifts out sooner?

Finally On my ET it's easy to change the belt but on the Vmax it's hell. I tried to do as in the manual (grab inner sheave, twist clockwise and push) but it wouldn't budge and it's almost impossible to get a grip on it with the belt on. Is there some trick to it? I had to do it with brute force and the belt kept getting stuck at the "hinge" for the clutch cover.

drew24

New member

I push on the helix and shove the belt down in the secondary while pushing and twisting the helix. Once the belt is down you can take the belt off around the bottom of the secondary and then slowly work the belt out of it so the sheaves don't slam together.

A couple of bucks

VIP Member

A 40* twist opens the secondary sooner than a 30* twist. By upping the degrees, you a making it easier for the secondary sheave to open. At 30* the secondary probably didn't start to open until 50 or 60 mph.

I push on the helix and shove the belt down in the secondary while pushing and twisting the helix. Once the belt is down you can take the belt off around the bottom of the secondary and then slowly work the belt out of it so the sheaves don't slam together.

I'll try that, thanks.

A 40* twist opens the secondary sooner than a 30* twist. By upping the degrees, you a making it easier for the secondary sheave to open. At 30* the secondary probably didn't start to open until 50 or 60 mph.

It's 40* now as far as I can tell from the manual but supposed to be 60. It says position 1-3 and 40* for Vmax 600 and Vmax 600E, i just saw in the supplement it says position 3-3 60* for Vmax 600XT. Are you sure it isn't the other way around? Now with 40* It's much easier to separate the sheaves by hand. In any case what's the effect, it shifts up earlier now?

Weatherbyman

Member

Sorry, but the advice you're getting is exactly the opposite of the effect of secondary preload. The more degrees preload of the secondary spring, the more force it takes to up shift. 60 degrees preload will require more force than 50 degrees. The more preload, the more rpm it takes to upshift provides all other factors remain unchanged.

Weatherbyman

Member

Provided. Sorry for the typo.

A couple of bucks

VIP Member

Boy o boy you weren't kiddin there. I had it completely @ss backwards.Sorry, but the advice you're getting is exactly the opposite.