Motodeficient

New member

2003 SX Viper-

Going to clean the powervalves this weekend, but have a question or two about adjustment afterwards.

This thread is very helpful:

http://www.totallyamaha.net/forums/showthread.php/55400-Setting-Your-Power-Valves

But I would like to ask for clarification on these points please:

Step 2. loosen the cables all the way up @ the servo cable adjusters

Does this mean screw the adjuster all the way into the servo body after loosening the locknut? (will probably be more obvious once I start the process)

Step 4. Insert the 2.5mm Allen wrench’s (or other suitable spacer), go back up to the servo and GENTLY tighten the cable adjusters so it pulls the two P/V housings together, so it just touches the wrench (chosen spacer), then pull out wrench and tighten the two bolts and the cable adjuster lock nut.

How do the two bolts that hold the powervalve into the housing tighten after the 2.5mm spacer is removed? How do they tighten without closing the 2.5mm gap?

Thanks in advance for helping a n00b out!

Going to clean the powervalves this weekend, but have a question or two about adjustment afterwards.

This thread is very helpful:

http://www.totallyamaha.net/forums/showthread.php/55400-Setting-Your-Power-Valves

But I would like to ask for clarification on these points please:

Step 2. loosen the cables all the way up @ the servo cable adjusters

Does this mean screw the adjuster all the way into the servo body after loosening the locknut? (will probably be more obvious once I start the process)

Step 4. Insert the 2.5mm Allen wrench’s (or other suitable spacer), go back up to the servo and GENTLY tighten the cable adjusters so it pulls the two P/V housings together, so it just touches the wrench (chosen spacer), then pull out wrench and tighten the two bolts and the cable adjuster lock nut.

How do the two bolts that hold the powervalve into the housing tighten after the 2.5mm spacer is removed? How do they tighten without closing the 2.5mm gap?

Thanks in advance for helping a n00b out!

Last edited:

drew24

New member

The 2.5mm spacer give the cable the correct amount of slack so the valve opens all the way but doesn't pull it tight. If the cable is too tight it will wear the end of the valve out where the cable connects and pull the cable through the end. it will all make sense once you get into it. And yes, screw the adjusters in to the servo which essentially makes the cable longer.

Motodeficient

New member

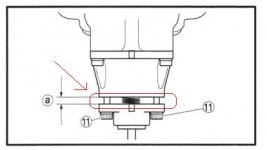

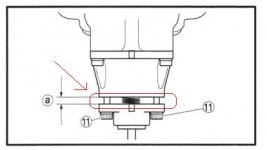

Thank you for the reply. I just don't understand how you tighten the two bolts (item 11) as per the instructions without it closing the 2.5mm gap once the spacer is removed?

Also some people mention removing the exhaust and header pipe to feel the position of the valves in the opening in order to adjust the valves- this is not 100% necessary?

Also some people mention removing the exhaust and header pipe to feel the position of the valves in the opening in order to adjust the valves- this is not 100% necessary?

Last edited:

drew24

New member

You want to close the gap after the spacer is removed. That will make the valve open the proper amount. You can remove the exhaust and do it that way but most will say the 2.5mm gap will be good. Basically the valve will be as far back as it can go with the 2.5mm space and then when you take the spacer out and tighten the bolts the valve will move forward 2.5mm and that should be good.

super1c

Super Moderator

That's guys got ya. The space is strictly to set cable slack. The. You tighten housing back down.

Motodeficient

New member

Ah, that makes perfect sense now. Told you they were dumb questions! Thanks for the help.

super1c

Super Moderator

Ah, that makes perfect sense now. Told you they were dumb questions! Thanks for the help.

No dumb questions. That's how we all learn this stuff!

Motodeficient

New member

Well I guess I need some more help.

I got the two outer valves adjusted with no problem. However for the center valve, even with the adjuster at the servo screwed all the way in, I can only get maybe 1mm gap at the power valve housing. It was already adjusted almost all the way in when I took the servo cover off, so I guess that previous owner had the same issue? What does this mean?

View attachment 61884

I got the two outer valves adjusted with no problem. However for the center valve, even with the adjuster at the servo screwed all the way in, I can only get maybe 1mm gap at the power valve housing. It was already adjusted almost all the way in when I took the servo cover off, so I guess that previous owner had the same issue? What does this mean?

View attachment 61884

Last edited:

Pretty sure you put at least one in the wrong slot. Never had a problem with them, and I learned the hard way, just like you. You'll have to re-read the manual again.

Last edited:

Motodeficient

New member

I didn't remove the cables from the servo housing. Maybe the previous owner did?

Motodeficient

New member

I think you are right though.

Last edited:

Yeah, the number 2 and 3 cross each other on the lower pic. They aren't supposed to do that. I guess you did check for pull throughs when you cleaned your valves? You will need to take off that pulley ( I think) and set them in the right order. Unfortunately, it means you have to do the adjustment over again because you change the pulley slots and the cables therefore need to be adjusted again. Both 2 and 3 also seem to be on the very same notch, that's nothing short of incredible if you ask me.

Motodeficient

New member

Yes I edited my last post.

Last edited:

You are looking for whether the cable end will chew itself out of the notch soon. Should be easy enough to see. Many people have upgraded their valves to a steel tip insert. Since you are going to take they off the pulley anyway, it's not that much of a job to unscrew from the holder.

Last edited:

Motodeficient

New member

Ok, I'll take a look at them and report back what I find. Thanks for the help.

Motodeficient

New member

Well the good news is the valves look completely fine to me.

Last edited:

Motodeficient

New member

What the hell that wheel isn't even it's own part on the parts diagram lol. I really have no idea how someone could break that piece

Last edited:

Can you take more pics of the servo wheel?

Motodeficient

New member

Not at the moment

Last edited: