hessracing

Member

I've already sucked dryer sheets into my reed cages your positive that none were broken you pulled all of them out and they are all installed properly? i want you to beat this thing too lol when I first got my SRX i had a wire rub through under neath the motor and was creating all kinds of hell.

yammitrip1

Member

Okay guys just changed the stator and it is doing the same thing. I am going to go out on a limb here and say it is not the electrical, because I have swapped spark plug caps, coils and now three stator...... all allotting the sled to act the same, runs good for a few mins and pulls like a sob and them let off and go to wack it bogs and cannot get it to come back most of the time. Allow sled to cool a few mins, like three to be real specific, fire it up and then it'll light on all three for a couple mins and die! so I am moving on the electrical side of things and going to start guessing its getting flooded out on that specific cylinder..

I do not beleive it is a stuck float because inhale had two different sets of crabs on it but hell ill check again.

Add to my list but to create a flooded cylinder is

Improper jetting

Don't plug the carbs into air box/or maybe a cracked vent line off carbs? NVR checked

Stuck float

Improper setting of floats

Bad reed valve/pedals

Bad powervalve cable or not installed properly

Anything else above I missed add to it, I am going to check tomorrow. I have such a sweet build here and this thing is really really starting to get to me.

I do not beleive it is a stuck float because inhale had two different sets of crabs on it but hell ill check again.

Add to my list but to create a flooded cylinder is

Improper jetting

Don't plug the carbs into air box/or maybe a cracked vent line off carbs? NVR checked

Stuck float

Improper setting of floats

Bad reed valve/pedals

Bad powervalve cable or not installed properly

Anything else above I missed add to it, I am going to check tomorrow. I have such a sweet build here and this thing is really really starting to get to me.

Since I'm the float valve advocate, and you probably already know this, but make sure the whole valve can move up and down. There's a little spring loaded pop-it on the top of the valve, but just because it's functioning, doesn't mean the valve is. The whole valve needs to slide up and down in it's "tube"

brethren

New member

I'm a big believer in swapping things, can you try swapping reed values and see if the dark plug moves to another cylinder?

Sent from my SGH-I337M using Tapatalk

Sent from my SGH-I337M using Tapatalk

Oh, I forgot, you tried multiple carb banks. Hmmm...... may not be the float valve. Just seems like you're flooding out some how.

A couple of bucks

VIP Member

How about a secondary grounding strap/wire on the PTO side.Mag is soaked

After reading it all again, I am leaning towards sh!tty spark on that side.

Last edited:

yammitrip1

Member

So your saying add a ground from the engine to the frame??

drew24

New member

If its not a tors issue it could be something in the clutching. Like its not back shifting. I was having problems with my stock viper last year bogging terribly bad. I threw a new secondary spring and a different helix in and it cured the problem. Not sure which it was but it was definitely one of the two. It was doing close to the same thing as you are stating.

yammitrip1

Member

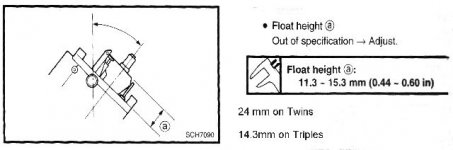

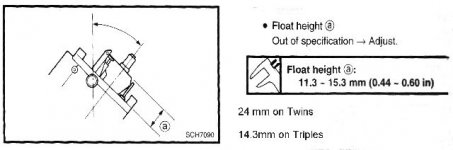

What's the spec for SX viper float height anyone? I think I found a problem!

yammitrip1

Member

Found the spec, where the heck do you measure the 13.3 mm from?

A couple of bucks

VIP Member

For Triples: take the carbs completely off the snowmobile. Remove the float bowls. Holding the carbs by the rack, looking at the carbs inlet needles and rotate the carbs till the float lightly rests on the needle(Approx. 45 degrees). Measure from the float bowl gasket surface to the top or highest most part of the float. Be sure to measure at both outer edges to make sure it's straight or even. If its out of spec, pry or bend very carefully the tab that rides in the center of the float to adjust the height. You might have to twist it to make it even on both sides of the float. After spec has been set, reassemble carbs.

Cut & pasted from Tech sec.

Cut & pasted from Tech sec.

Last edited:

yammitrip1

Member

Why does Yamaha spec say 13.3 + or - 2 and that spec says 14.3? Which do I follow, mine were at like 11.3

A couple of bucks

VIP Member

Where are the others?

A couple of bucks

VIP Member

Is the seat ok?

yammitrip1

Member

I got 11.7, 11.6, and 11.3, oddly enough seems on the rich side of things, I looked in the search and guys set there on some of these vipers to 13.5 to 14.5

yammitrip1

Member

Where do I set them is the better question

A couple of bucks

VIP Member

Actually .... O ring. 34,36 & 37.

https://partstream.arinet.com/Mobil...ypAICXl6umukGNMDADhXGVpFimb-8rPCrUHY0UA1.html

Those are the bowls "fuel cork".

https://partstream.arinet.com/Mobil...ypAICXl6umukGNMDADhXGVpFimb-8rPCrUHY0UA1.html

Those are the bowls "fuel cork".

Last edited:

Why does Yamaha spec say 13.3 + or - 2 and that spec says 14.3? Which do I follow, mine were at like 11.3

In my manual I only see 11.3 to 13.3. I don't have a + - 2mm. I may be missing a service bulletin or update.

With that said, some people just make sure the flat / top portion of the float is parallel with the float bowl mating surface at valve closing. I've done this on my vipers and haven't had a problem with fuel starvation.

yammitrip1

Member

It's stinking fixed fellas!!!!!!!!!! It's a ripper! With a mild port job and slps, good god it pulls!