BigMac

New member

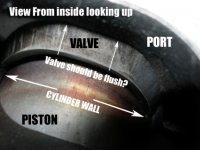

With the servo powered up, is it better to adjust to a gap between the two valve housings 2.0-3.5 mm , or better to adjust until the power valve can be felt exactly flush with the cylinder wall when feeling from inside the exhaust port?

The two are not necessarily the same...

The two are not necessarily the same...

98srx6

New member

You want the valves to be flush when completely open.

BigMac

New member

98srx6 said:You want the valves to be flush when completely open.

I assume that "completely open" means the servo energized with the tester cable and 12volt battery....

I note that getting the valves flush may very well mean substantially more cable housing gap than the 3.5 mm that Yamaha calls for. I just replaced my number 2 cable tonight. The other two cables are apparently stretched enough that 3.5 mm isn't even close to flush.

yamaholic22

Active member

yup it is better to get them flush when the servo is at full open, that is the best they can be. I adjusted mine to the spec (the larger end of the spec) and then felt if they were flush and they were way off, now i always feel the port to adjust them.

S.S.Viper

New member

Ok...Now I'm a tad confused...got the Powervalve tester...Hooked it up...felt inside the port...and it feels like my Valves are beyond the housing...like 2-4mm(to much)...So if I adjust them back to the "flush" position...wouldn't they be scraping against the piston when its back in idle position?...Oh..and the guys a Bender said

you could gain an extra 2-3hp if dialed in correctly...is this true?...

you could gain an extra 2-3hp if dialed in correctly...is this true?...

shortstop20

New member

- Joined

- Mar 6, 2005

- Messages

- 1,583

- Age

- 39

- Location

- Stickney, South Dakota

- Website

- www.snowmobilefanatics.net

Yes it makes a big difference if they're clean and synchronized!

vipertripplexxx

New member

I seem to remember that the

valve

bottoms out, it can't possibly hit the cylinder, from a misadjusted cable, correct?

valve

bottoms out, it can't possibly hit the cylinder, from a misadjusted cable, correct?

Correct.

Having a fatal design flaw like broken cables taking out a motor would not be very yamaha like.

Having a fatal design flaw like broken cables taking out a motor would not be very yamaha like.

S.S.Viper

New member

Sweet!!...thanks guys..I'll be adjusting them tomorrow...Nothing

like discovering a few extra HP's when doin simple maintenance

checks...hands down this site definetly rocks!!!

like discovering a few extra HP's when doin simple maintenance

checks...hands down this site definetly rocks!!!

Can someone tell me if you reach up in the exhaust port and the valves are "in" (twards the exaust port or the front of the sled) just a tad in comparision to the cylinder wall, should I be bringing them out (twards the cylinder) totally flush? This is an SRX but I would assume it's the same. I have mine apart now and want to finish it tonight. I had to replace all 3 valves and one cable.

Before I started, I did drop the RPM's below 1000 and the servo motor appeared to pull them open all the way. I then hit the kill swith. Someone on the site told me this is how to get them to full open. Did I do this correct? So as it sits the cables are pulled tight and the valves should be pulled all the way in (or out?). I guess I have the same confusion as to once the sled starts, wont the valves go in twards the piston when they release if you adjust them flush to the wall when they are pulled open thus hitting the piston?

I'm confused....

Before I started, I did drop the RPM's below 1000 and the servo motor appeared to pull them open all the way. I then hit the kill swith. Someone on the site told me this is how to get them to full open. Did I do this correct? So as it sits the cables are pulled tight and the valves should be pulled all the way in (or out?). I guess I have the same confusion as to once the sled starts, wont the valves go in twards the piston when they release if you adjust them flush to the wall when they are pulled open thus hitting the piston?

I'm confused....

Last edited:

S.S.Viper

New member

I'm kinda in the same boat...but from what I gather and noticed...I dropped my valves to flush mode(well kinda) and they are still clear from the piston...I've actually hand turned the primary to check and its fine...in fact...from what I noticed theirs some sorta stop in there to prevent them from goin any further...but I'm on a viper...but I'm sure the SRX would be the same...

Now here's my confusion...I'lll be taking a digital picture tomorrow...I've adjusted mine down right in to the last thread...BIG time slack on the cable!!!...and when I open them(tester cable)...they still have 1mm more until flush...is this acceptable?...Why so slack?...and not flush...?...I've taken my valves and cleaned everything off in November, so I know there's nothing wrong with them...

I'll send pict tomorrow..

YOP

Now here's my confusion...I'lll be taking a digital picture tomorrow...I've adjusted mine down right in to the last thread...BIG time slack on the cable!!!...and when I open them(tester cable)...they still have 1mm more until flush...is this acceptable?...Why so slack?...and not flush...?...I've taken my valves and cleaned everything off in November, so I know there's nothing wrong with them...

I'll send pict tomorrow..

YOP

anyone?

Millinocket Rocket

New member

that's what i did last night to mine-- last season i adjusted them the way the tech bulletin said- with the powervalve housings to 2- 3.5 mm. last night i idled it down under 1000 rpm's, waited for the servo to stop twitching and then the reference marks i made last season on the servo lined right up. so i shut it down, took off the y-pipe and felt the PV's in the exhaust port. two of them were recessed from the port and the middle one was flush. so i loosened the adjuster nut on the cables and adjusted them in flush. you can feel them moving as you adjust them. that's how i'm reading it should be done.

vipertripplexxx

New member

Too much book knowledge?

O.K. let me get this straight.. You guys are opening the P.V.'s and then setting them too a tight clearance on the cylinder?

When you use the tester or let it idle down, this opens the power valves, which is tightening up the cable. This is the method of measuring clearance on the valve housing, which is the way the manual says to do it, and the only way I have ever done it.

This new method of feeling the cylinder wall would require the valves to be fully closed, i assume,... So now using the tester, or idling down would not be required.? I would mark the cable winder with a scribe when idling, so if the servo motor moves when you shut down the machine you can turn it back to the mark. Then adjust the valves with the "feel method"

S.S.viper and Snowdog, don't take my word for it, but you sound right in Questioning this method. Heck even the Bender PDF file says to do it the wrong way. I think bender was smoking something!!! Adjust to fully open then put zero clearance on the cylinder wall?? WHAT THE F***

Here's the linkhttp://www.benderracing.com/Default.cfm?SubPage=CustomerSupport_SupportDocuments

O.K. let me get this straight.. You guys are opening the P.V.'s and then setting them too a tight clearance on the cylinder?

When you use the tester or let it idle down, this opens the power valves, which is tightening up the cable. This is the method of measuring clearance on the valve housing, which is the way the manual says to do it, and the only way I have ever done it.

This new method of feeling the cylinder wall would require the valves to be fully closed, i assume,... So now using the tester, or idling down would not be required.? I would mark the cable winder with a scribe when idling, so if the servo motor moves when you shut down the machine you can turn it back to the mark. Then adjust the valves with the "feel method"

S.S.viper and Snowdog, don't take my word for it, but you sound right in Questioning this method. Heck even the Bender PDF file says to do it the wrong way. I think bender was smoking something!!! Adjust to fully open then put zero clearance on the cylinder wall?? WHAT THE F***

Here's the linkhttp://www.benderracing.com/Default.cfm?SubPage=CustomerSupport_SupportDocuments

vipertripplexxx

New member

O.K. got it

Bender says to adjust so the valve is flush with the top of the port, not flush to the cylinder wall. Theres the misunderstanding. Flush to the cylinder wound be fully closed position, flush with top of port is fully open.

Bender says to adjust so the valve is flush with the top of the port, not flush to the cylinder wall. Theres the misunderstanding. Flush to the cylinder wound be fully closed position, flush with top of port is fully open.

Millinocket Rocket

New member

tripplex- that's right - as far as i know. at first i stuck my finger into the cylinder and couldn't feel anything but cylinder wall, so i came back to the port and could barely feel anything on the middle one, because it was flush with the top. i felt the other two and you could feel the difference- they were recessed (and those were the ones that needed to be adjusted) am i on the right track here??

vipertripplexxx

New member

Yes, feel the top of the port, not the cylinder wall.

BigMac

New member

Millinocket Rocket said:that's what i did last night to mine-- last season i adjusted them the way the tech bulletin said- with the powervalve housings to 2- 3.5 mm. last night i idled it down under 1000 rpm's, waited for the servo to stop twitching and then the reference marks i made last season on the servo lined right up. so i shut it down, took off the y-pipe and felt the PV's in the exhaust port. two of them were recessed from the port and the middle one was flush. so i loosened the adjuster nut on the cables and adjusted them in flush. you can feel them moving as you adjust them. that's how i'm reading it should be done.

The thing I noticed with Yamaha's method of measuring the clearance between the block halves is that it assumes there's been no cable stretch. Measuring that way, with each block gap at exactly 3mm, there was a wide variation in how much each of my power valves was recessed. Likewise, if I adjusted the cables so that all the valves were flush, there was wide variation in the amount of gap at the block halves, with one of mine at almost 4.5 mm. If people, including Yamaha service techs, are using Yamaha's recommended methods, there are a lot of misadjusted power valves out there if we're using flush-with-the-port as the TRUE criterion.

I conclude that these minor variations in power valve adjustment have little effect on performance in the real world. I read here on TY about people whose SRX's and Vipers are running fantastic all year, only for them to find out at the end of the season that one or two of their power valve cables have pulled through and the valves weren't working at all. I'm not saying we shouldn't keep them adjusted, but I've kind of decided that obsessing over flush vs recessed a little is probably unwarranted.

S.S.Viper

New member

Okay...now I hafta go back outside and check again...I just took this pick of the servo...cable screws are set right in...and you can see the cables just loose and hanging(I don't think this is right)...hmmm..I'm gunna hafta reread above and check em...

Rocket...I'm pretty sure your right...I swear I'm doin it right..Im not feeling the cylinder...but the port...and I'm still a 1mm from being flush from top on all 3...

ServoSettings.jpg

Rocket...I'm pretty sure your right...I swear I'm doin it right..Im not feeling the cylinder...but the port...and I'm still a 1mm from being flush from top on all 3...

ServoSettings.jpg

Attachments

Last edited:

S.S.Viper

New member

Here's another pict to see if I got this right...I'm sure I do...basically the pict shows

the valve in its "closed" state....and the front of the valve(facing piston) should be towards the tips of the arrows(port wall)...correct?...All and all I guess Big Mac is right...They where recessed a lil far...maybe its good...but

adjuster nuts seem to far to me...

I'll check again tomorrow

the valve in its "closed" state....and the front of the valve(facing piston) should be towards the tips of the arrows(port wall)...correct?...All and all I guess Big Mac is right...They where recessed a lil far...maybe its good...but

adjuster nuts seem to far to me...

I'll check again tomorrow