V-Max 600SX races at idle, bogging PART TWO PROBLEM FOUND

I`m in the need of more attention so I started a new thread with some more "consistent" facts.

Previous thread: http://www.totallyamaha.net/forums/showthread.php?t=18448

I`m working on a 1997 V-Max 600 SX for a friend, the problem is that it races on idle, from 2000rpm to 2500rpm, then when you hit the throttle it starts bogging when the primary engages (maybe just before it engages).

The sled will move forward slowly but when you get the rews above 5500rpm or so, it rews like hell and pulls strong.

I took the carbs off and cleaned them, looked good though. Know I have the carbs off again because the last time I didn`t remove the air screws due to a missing screwdriver in my workshop, so I took the carbs off again and removed the air jets, they were all clean.

Reeds looks fine, no broken blades, checked them visually without removing the inlet boots, also tryed pushing the blades with my fingers and they seemed fine.

I tried spraying CRC 5-56 (universal lubricant, I couldn`t find the can with starter fluid) around the crankseal PTO side , I also tried spraying around the inlet boots/carbs but I could not hear any differnce on the engine idle. I did not try so spray around the magneto side crankseal, I somehow forgot.

I will get a can with real starte fluid and do it again, will I reach the magneto side seal without removing anything?.

Since I have the carbs off now I checked the air/gas screw settings.

One screw was 2 turns out and the other one was around 1 and 6/8 turns out.

I remember on my moped when I fiddled with the air/gas screw, if I turned it too much out the engine would idle high and the throttle response was kind of boggish, when I turned the screw too much in the engine died.

Could the air/gas screws be to far out on the V-Max engine?.

Gees I feel like a dork, my friend hasn`t ridden the sled since she bought it, she brought me with her as a "technical expert" (hehe) so that she would know that she didn`t buy any crap. The sled seemed fine when I rode it into the trailer three months ago, but a month ago when I was going to ride the sled from my friend to my house (had been sitting since we bought it) it was hard to start, and when I finally got it running it had the symptoms described above.

Gees I`m clueless.. or what it`s called.. .

I know it might be stupid to start two threads about the same sled but I just felt that I needed to, sorry .

.

Joakim.

I`m in the need of more attention so I started a new thread with some more "consistent" facts.

Previous thread: http://www.totallyamaha.net/forums/showthread.php?t=18448

I`m working on a 1997 V-Max 600 SX for a friend, the problem is that it races on idle, from 2000rpm to 2500rpm, then when you hit the throttle it starts bogging when the primary engages (maybe just before it engages).

The sled will move forward slowly but when you get the rews above 5500rpm or so, it rews like hell and pulls strong.

I took the carbs off and cleaned them, looked good though. Know I have the carbs off again because the last time I didn`t remove the air screws due to a missing screwdriver in my workshop, so I took the carbs off again and removed the air jets, they were all clean.

Reeds looks fine, no broken blades, checked them visually without removing the inlet boots, also tryed pushing the blades with my fingers and they seemed fine.

I tried spraying CRC 5-56 (universal lubricant, I couldn`t find the can with starter fluid) around the crankseal PTO side , I also tried spraying around the inlet boots/carbs but I could not hear any differnce on the engine idle. I did not try so spray around the magneto side crankseal, I somehow forgot.

I will get a can with real starte fluid and do it again, will I reach the magneto side seal without removing anything?.

Since I have the carbs off now I checked the air/gas screw settings.

One screw was 2 turns out and the other one was around 1 and 6/8 turns out.

I remember on my moped when I fiddled with the air/gas screw, if I turned it too much out the engine would idle high and the throttle response was kind of boggish, when I turned the screw too much in the engine died.

Could the air/gas screws be to far out on the V-Max engine?.

Gees I feel like a dork, my friend hasn`t ridden the sled since she bought it, she brought me with her as a "technical expert" (hehe) so that she would know that she didn`t buy any crap. The sled seemed fine when I rode it into the trailer three months ago, but a month ago when I was going to ride the sled from my friend to my house (had been sitting since we bought it) it was hard to start, and when I finally got it running it had the symptoms described above.

Gees I`m clueless.. or what it`s called.. .

I know it might be stupid to start two threads about the same sled but I just felt that I needed to, sorry

.

.Joakim.

Last edited:

Sounds like the problem I had with a 96 Vmax 600 twin. It ended up being the fuel pump. check the output of the pump through the rpm range you are having problems with by T-ing into the line with a pressure gauge. Rev it and see if the pressure is dropping off in the rpm range which you are having issues with. If it is you may be starving the engine for fuel when it bogs and then the pump "kicks" back in outside that rpm range and brings the engine back to life.

Ok Mills thanks for the tip .

.

The idle is kind of wierd because when it drops from 2500 to 2000rpm it`s just like you shut off the engine with the ignition key and then turn it on before the engine has stopped.. if you see what I mean.. it might be firing in between but it seems kind of wierd.

What kind of pressure gauge should I use?. I`ve never tested a fuel pump before..

How does that pump work?.

.

. The idle is kind of wierd because when it drops from 2500 to 2000rpm it`s just like you shut off the engine with the ignition key and then turn it on before the engine has stopped.. if you see what I mean.. it might be firing in between but it seems kind of wierd.

What kind of pressure gauge should I use?. I`ve never tested a fuel pump before..

How does that pump work?.

kixx007

Member

Sounds like your throttle cable is misadjusted (too tight) and TORS is kicking on..

Hey kixx007 .

.

Sorry man, TORS is allready disabled... .

I was thinking, what if I feed the carbs with gas from two bottles with a hose connected to each bottle?.

.

.Sorry man, TORS is allready disabled... .

I was thinking, what if I feed the carbs with gas from two bottles with a hose connected to each bottle?.

daman

New member

kimoaj you still messing with this???? man you gota get that comp. test done dude buy a gauge if ya have to.

Hey daman yes I am  .

.

Gees you see I`m a poor guy, can`t afford a comp tester .

.

I know my friend has one I`m just hoping that he will remember to bring it the next time he comes home.

I did a little comp test, hehe, took the plugs out, put my thumb in one of the plug holes and then turned the engine by rotating the primary, both cylinders seemed to have lots of pressure.

Yeah I know it`s way to un-accurate so I will try to get that comp tester from my friend.. .

.

.Gees you see I`m a poor guy, can`t afford a comp tester

.

.I know my friend has one I`m just hoping that he will remember to bring it the next time he comes home.

I did a little comp test, hehe, took the plugs out, put my thumb in one of the plug holes and then turned the engine by rotating the primary, both cylinders seemed to have lots of pressure.

Yeah I know it`s way to un-accurate so I will try to get that comp tester from my friend.. .

TJ500

Member

yes..... the compression test??????...

was just thinking of spark plug boots and or ignition wires.... something else to check..

but first...

why is the idle set so high?.... should be around 1500 RPM, not 2500....

was just thinking of spark plug boots and or ignition wires.... something else to check..

but first...

why is the idle set so high?.... should be around 1500 RPM, not 2500....

Another friend of mine has a 1996 V-Max 600 DX, maybe I could borrow his coil and see if it made any difference, just to eliminate the coil.

I haven`t touched the idle screw so I don`t know why it is so high.. I can`t recall that it was that high when I rode it into the trailer when we picked the sled up.. .

Wierd.

I haven`t touched the idle screw so I don`t know why it is so high.. I can`t recall that it was that high when I rode it into the trailer when we picked the sled up.. .

Wierd.

TJ500

Member

your audio/video soooooo resembled a failing ignition cct.... using your buds coil/wire/boot assembly might be an inexpensive test...

just hope he doesn't live 400 miles away!!!!

we all want to see this solved for you SOON...

tj..

just hope he doesn't live 400 miles away!!!!

we all want to see this solved for you SOON...

tj..

ok TJ500 .

.

When listening to the idle it sounds more like a "real error" then false air or something because the idle racing is so "on/off" so maybe I should ask my friend about borrowing that coil. And, he only lives 2kilometers away from me and I`m sure he`d like to help me.

Nice to hear that you also want to see this solved soon .

.

I think I will be reassembling the carbs tomorrow and put them back on the sled. I`m also going to put fresh gas in the tank.

When you empy your tank, how do you usually do it?. Physically remove the tank or drain it through the fuel line that goes to the pump?.

.

.When listening to the idle it sounds more like a "real error" then false air or something because the idle racing is so "on/off" so maybe I should ask my friend about borrowing that coil. And, he only lives 2kilometers away from me and I`m sure he`d like to help me.

Nice to hear that you also want to see this solved soon

.

. I think I will be reassembling the carbs tomorrow and put them back on the sled. I`m also going to put fresh gas in the tank.

When you empy your tank, how do you usually do it?. Physically remove the tank or drain it through the fuel line that goes to the pump?.

TJ500

Member

jack the rear of the sled as high as possible and then siphon the fuel out of the tank with a hose that is placed strategically where the gas has collected...

don't remove the tank!

tj

don't remove the tank!

tj

daman

New member

Yes.... try the coil too!!!

dootime

New member

I posted eariler in the week about a 96 vmax 600 I was working on and I finally resolved my problem, so I have something for you to check. I found that the carbs were out of sync. The throtle rod between the carbs has a adjustment screw on the clutch side carb. The set screw had vibrated loose and would catch the rod sometimes and not keep the carbs shuting properly.

mulderdad

New member

Did you do a compression test yet?

Most auto parts stores have a vacuum/pressure gage kit for around $15-20 US. I got mine at Napa. The kits usually come with several fitting and flexible hose so that you can “tap” into the vacuum or pressurized system you want to monitor. Make sure that what ever gage you buy says it can be used for fuel pressure testing or you may damage the internal parts of the gage if it cannot handle pressurized fuel.

Once you get the gage, take your air box off and use a T-fitting to tap into the lines leading from your pump to the carbs (pressure side of pump) and connect the T-fitting to the gage using the SAME diameter tubing the runs from the pump to the carbs. Start the sled and rev it through a wide rpm range to see if it varies. More than a 5 psi change and you probably have problems in your pump/lines/float valve/vacuum line from crank case to pump. Check the lines to each carb separately. While you are doing this take a look at the rubber coated aluminum clips that hold and locate your fuel lines. Make sure one of them isn’t pinching off a fuel line.

The pumps usually work off of the pressure differential created in the crank case. This pressure differential actuates a diaphragm in the pump sucking it back and forth to create a pumping action that sucks fuel in and sends it out to your carbs. There will be a rubber hose running from the bottom of the crank case to the pump. If it has a crack or hole in it, it could be causing some issues with your fuel pump. So, if you do find a fuel pressure problem this hose may be a good (cheap) way to find out what the problem with the pump is.

If you don’t find any problems with the fuel delivery system then I would try a couple of the other suggestions like checking to make sure the carbs are sync’d and replacing the ignition with your buddies.

Hope you get the problem figured out soon.

Mills

Once you get the gage, take your air box off and use a T-fitting to tap into the lines leading from your pump to the carbs (pressure side of pump) and connect the T-fitting to the gage using the SAME diameter tubing the runs from the pump to the carbs. Start the sled and rev it through a wide rpm range to see if it varies. More than a 5 psi change and you probably have problems in your pump/lines/float valve/vacuum line from crank case to pump. Check the lines to each carb separately. While you are doing this take a look at the rubber coated aluminum clips that hold and locate your fuel lines. Make sure one of them isn’t pinching off a fuel line.

The pumps usually work off of the pressure differential created in the crank case. This pressure differential actuates a diaphragm in the pump sucking it back and forth to create a pumping action that sucks fuel in and sends it out to your carbs. There will be a rubber hose running from the bottom of the crank case to the pump. If it has a crack or hole in it, it could be causing some issues with your fuel pump. So, if you do find a fuel pressure problem this hose may be a good (cheap) way to find out what the problem with the pump is.

If you don’t find any problems with the fuel delivery system then I would try a couple of the other suggestions like checking to make sure the carbs are sync’d and replacing the ignition with your buddies.

Hope you get the problem figured out soon.

Mills

Last edited:

Hey guys !

Thanks alot for the replys ! .

TJ500 I used the gravity method when I drained the tank.

Mulderdad, no compression test yet, will not be necessary.

Dootime, the carbs are not out of sync but thanks for the tips.

Mills, thanks alot for the tip but it isn`t the fuel pump.

I figured out what the problem is. Keep on reading.

Today cleaned the carbs, removed all jets and the air screw + air/gas mixture screw. Blew through everywhere with compressed air. Turned air/gas screw 1,5 turns out according to the specs on the tech side.

I measured the float height. 22mm when not compressing the little nob, 20mm when compressed.

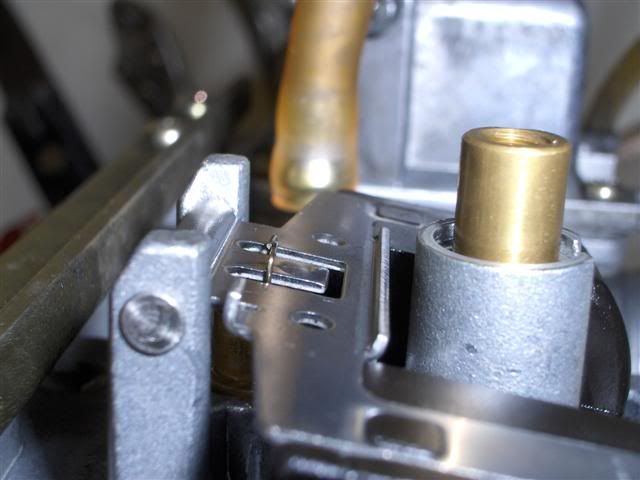

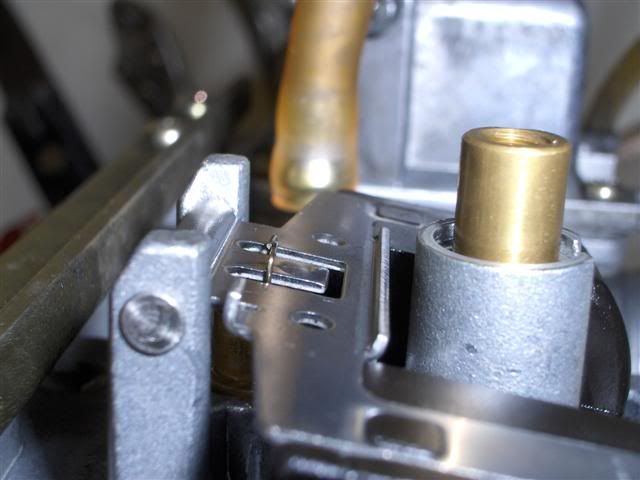

I attached a whose to the fuel connector and blew through it while I slowly pushed the float down, it closed when it was in the position that you see in the picture.

Does the floats get bent and get out of adjustment?. I have never adjusted a float in my life.

Now it`s time to drink some coke, notice the professional opening method.

When draining the tank I simply put a wood "support" under the rear of the sled so that the fuel would gather in the front of the tank.

I then put my mouth on the end of the hose and sucked until the gas reached my mouth and then the gas started flowing.

It was about 15liters of gas in the tank, kind of wierd I thought because the needle was below 1/4 full.

However.

I pulled the plugs and started pulling so that I would get the gas into the carbs faster. Put the plugs in and pulled 7-8 times then it started.

It idled just like before and I also took it for a short ride just to get the new fuel into the system. No difference, still bogging from 3000rpm to 4500rpm.

I drove the sled right back into the garage so that I could test the magneto side crank seal. (my father found the start gas in our old Fordson Dexta tractor, was hard to start the last time hehe). So now I had real start gas to use as a tester.

Here is a video clip of the results.

vmaxvideoclip (1,8mb)

Sorry for the pinnacle logo in the beginning, trial version.

I put my thumb up when I spray. The can was almost empty so it was kind of hard but I did get a little out of it.

For those who doesn`t bother to download the video clip, I can unveil that it was infact the crank seal that has been causing my problems. When I sprayed the starter fluid into the little hole that leads into the seal (or near the seal) the engine rewed up and it was easy to notice.

So I guess the problem is a faulty crank seal.

Right now I`m sitting her listenting to the boss (Bruce Springsteen) , drinking some Pepsi Max and looking forward to digging into that V-Max engine.

I would appreciate it if you guys can help me / guide me through this.

I`ve wrenched quite much throughout the years but I have never digged into a sled engine. I`ve worked on a few 4cyl 4stroke motorcycle engines, (totally apart and then reassembled), some boat outboards, some car engines (replacing timing belts/adjusting valves/seals) so I feel that I should be up to the job and I am really looking forward to getting some more experience.

I bet the sled has been run in this condition by the previous owner so I guess it will be best to tear it apart and inspect the cylinders/pistons?.

This will be an economical rebuild, only things that HAS to be changed will be changed. I dislike to change parts that not has to be changed.

I will need the new seals, gaskets to rebuild the engine and, the question is wether to change pistons or atleast rings?.

If it was my sled I would do it without a doubt but it isn`t my sled.

Well guys that`s all for now!.

Joakim.

Thanks alot for the replys ! .

TJ500 I used the gravity method when I drained the tank.

Mulderdad, no compression test yet, will not be necessary.

Dootime, the carbs are not out of sync but thanks for the tips.

Mills, thanks alot for the tip but it isn`t the fuel pump.

I figured out what the problem is. Keep on reading.

Today cleaned the carbs, removed all jets and the air screw + air/gas mixture screw. Blew through everywhere with compressed air. Turned air/gas screw 1,5 turns out according to the specs on the tech side.

I measured the float height. 22mm when not compressing the little nob, 20mm when compressed.

I attached a whose to the fuel connector and blew through it while I slowly pushed the float down, it closed when it was in the position that you see in the picture.

Does the floats get bent and get out of adjustment?. I have never adjusted a float in my life.

Now it`s time to drink some coke, notice the professional opening method.

When draining the tank I simply put a wood "support" under the rear of the sled so that the fuel would gather in the front of the tank.

I then put my mouth on the end of the hose and sucked until the gas reached my mouth and then the gas started flowing.

It was about 15liters of gas in the tank, kind of wierd I thought because the needle was below 1/4 full.

However.

I pulled the plugs and started pulling so that I would get the gas into the carbs faster. Put the plugs in and pulled 7-8 times then it started.

It idled just like before and I also took it for a short ride just to get the new fuel into the system. No difference, still bogging from 3000rpm to 4500rpm.

I drove the sled right back into the garage so that I could test the magneto side crank seal. (my father found the start gas in our old Fordson Dexta tractor, was hard to start the last time hehe). So now I had real start gas to use as a tester.

Here is a video clip of the results.

vmaxvideoclip (1,8mb)

Sorry for the pinnacle logo in the beginning, trial version.

I put my thumb up when I spray. The can was almost empty so it was kind of hard but I did get a little out of it.

For those who doesn`t bother to download the video clip, I can unveil that it was infact the crank seal that has been causing my problems. When I sprayed the starter fluid into the little hole that leads into the seal (or near the seal) the engine rewed up and it was easy to notice.

So I guess the problem is a faulty crank seal.

Right now I`m sitting her listenting to the boss (Bruce Springsteen) , drinking some Pepsi Max and looking forward to digging into that V-Max engine.

I would appreciate it if you guys can help me / guide me through this.

I`ve wrenched quite much throughout the years but I have never digged into a sled engine. I`ve worked on a few 4cyl 4stroke motorcycle engines, (totally apart and then reassembled), some boat outboards, some car engines (replacing timing belts/adjusting valves/seals) so I feel that I should be up to the job and I am really looking forward to getting some more experience.

I bet the sled has been run in this condition by the previous owner so I guess it will be best to tear it apart and inspect the cylinders/pistons?.

This will be an economical rebuild, only things that HAS to be changed will be changed. I dislike to change parts that not has to be changed.

I will need the new seals, gaskets to rebuild the engine and, the question is wether to change pistons or atleast rings?.

If it was my sled I would do it without a doubt but it isn`t my sled.

Well guys that`s all for now!.

Joakim.

Last edited:

daman

New member

yup definitly a seal, you got some work to do now.

Glad you finaly found the damn thing. good luck!!

good luck!!

Glad you finaly found the damn thing.

good luck!!

good luck!! .

.Let`s say that I only need to replace the seals and all the gaskets and put new rings on the piston, how much will it cost me?. Maybe I should talk with Rich.

I took a look at the microfiche, the crankshaft bearing was quite expensive so I hope I wount have to change any of them.

I don`t have to remove any of the bearings from the crank?.

Since those seals sits 50% in the upper part and 50% in the lower part, should it be installed on the crank, then let the crank slip down into the upper crankhouse, then install the lower part?.

Or, should the crankcases be put together and the seal installed afterwords?.

daman

New member

I'm shure all you need is seals(do all of them) and gaskets, but wile you are in ther look at everything good mabie re ring it too... IF things

look good put her back to gether. $.02

look good put her back to gether. $.02

Last edited: