Hi guys!

Viper Mountain 5000km on the clocks.

Yesterday my good old yammi let me down, it`s the first time a Yamaha has le me down.

I think I need to tell the whole story so here goes:

Last year I had some minor cooling problems, the cooling light came on a few times at the end of the season and I had to add some more water/glycol. But I only had to add water/glycol one time (last ride).

So when I ordered some parts from Rich due to my pre-season tuneup, I ordered all the gaskets/seals for the waterpump.

Since I have been building a trailer this fall I got delayed with my sled pre-season tuneup, so I decided to skip the waterpump and just have a look after the first startup. I held a mirror down under the waterpump and I could see drops coming out of the weep hole.

So I took the engine out of the sled, replaced all the seals in the waterpump

and put the engine back in.

After having filled it up with water/glycol I used my hands and "compressed" the cooling hoses and I could see that the water level in the expansion tank got lower, so air in the system was replaced with water. I did this alot on all the hoses I could see.

(I couldnt find any bleeding screws, and I read that the Viper ER had one buy my mtn didnt).

So I figured out that I needed to pay attention to the coolant level after I had started it, which I did, and I added coolant until the level was stabilized.

I also put my hands on running board coolers and the rear cooler to make sure they were hot and they were indeed hot.

So I thought I had aired it good enough, or ??

As for the oil pump I opened the bleeding screw before I started the sled, I made sure that oil came out of the screw. I could see that it drippled pretty good.

Then I started the sled and let it idle for a few minutes, I then opened the oilpump bleed screw again just to make sure it was aired properly.

As a part of my pre-season tuneup I bought a heelclicker kit. I used the red spring, 5 grams in tip 3.3 in heel. The engagement rpm was a little high (just below 5000) and "brutal" but I`ve heard that clickers act that way so I didnt care that much about it.

Last weekend we went riding in Sweden, it was about -22 celcius and the trails were freakin hard with very little cooling snow for the slides/engine.

I had new slides and my girlfriend also came along as my passenger.

After riding 500 meters we had to stop cause I was freezing my hands off, before I stopped I heard that the track/slides squeeled. When I then hit the throttle again the track had melted into the slides so the track didnt spin.

I had a friend lift the rear end of the sled and I blipped the throttle so that the track loosened.

We continued riding and it didnt take long before my cooling light came on.

I stopped and put snow on the runningboards.

Continued riding but the cooling light returned and I decided to try to keep out of the trail to get as much cooling snow as possible.

But I did ride with the cooling light on for some time.

I also noticed that the rews were kind of high, does the engagement rpm affect the rpms throughout the hole rpm scale? (I wonder this since my engagement rpm was just under 5000).

So my question is, could the fact that there was little cooling-snow which made the slides hot which again made the track heavy to turn, which again made the engine raise its rpm to keep the track spinning, that in turn made the engine run hotter and because of the lack of cooling snow for the coolers also made the engine run hot?.

Anyway later on the day the trail got softer and I had no problems when we went back to our trailers. We rode about 70km that day.

When we got home I put my sled in the garage to figure out what was wrong with my heated grips. I then noticed that the oil consumption seemed little, I did fill the tank up to the lid before I took my first ride this year, so I thought it had used little oil.

Therefor I aired the pump one more time.

Yesterday we went for a ride back home and the trail was alot softer then it was in Sweden. But due to little snow we had to ride a gnarly trail with low speed, so I did get my cooling light on. I stopped and put snow on the running boards then continued for a 150m and then the rest of the guys decided to stop for a few minutes and then when we continued my cooling light was gone.

We rode up a long hill and in the middle of the hill the sled made a little "boooo burble" but after a split second it was back to normal, and then after 100meters it stopped. I pulled the plugs and found out that the center plug had some aluminium bits on it, so I knew what had happened.

Towed the sled down to the trailer, went home and tore it apart.

Here are some pictures:

Used the oil trick to get the primary off, with a cut down puller.

Viper Mountain 5000km on the clocks.

Yesterday my good old yammi let me down, it`s the first time a Yamaha has le me down.

I think I need to tell the whole story so here goes:

Last year I had some minor cooling problems, the cooling light came on a few times at the end of the season and I had to add some more water/glycol. But I only had to add water/glycol one time (last ride).

So when I ordered some parts from Rich due to my pre-season tuneup, I ordered all the gaskets/seals for the waterpump.

Since I have been building a trailer this fall I got delayed with my sled pre-season tuneup, so I decided to skip the waterpump and just have a look after the first startup. I held a mirror down under the waterpump and I could see drops coming out of the weep hole.

So I took the engine out of the sled, replaced all the seals in the waterpump

and put the engine back in.

After having filled it up with water/glycol I used my hands and "compressed" the cooling hoses and I could see that the water level in the expansion tank got lower, so air in the system was replaced with water. I did this alot on all the hoses I could see.

(I couldnt find any bleeding screws, and I read that the Viper ER had one buy my mtn didnt).

So I figured out that I needed to pay attention to the coolant level after I had started it, which I did, and I added coolant until the level was stabilized.

I also put my hands on running board coolers and the rear cooler to make sure they were hot and they were indeed hot.

So I thought I had aired it good enough, or ??

As for the oil pump I opened the bleeding screw before I started the sled, I made sure that oil came out of the screw. I could see that it drippled pretty good.

Then I started the sled and let it idle for a few minutes, I then opened the oilpump bleed screw again just to make sure it was aired properly.

As a part of my pre-season tuneup I bought a heelclicker kit. I used the red spring, 5 grams in tip 3.3 in heel. The engagement rpm was a little high (just below 5000) and "brutal" but I`ve heard that clickers act that way so I didnt care that much about it.

Last weekend we went riding in Sweden, it was about -22 celcius and the trails were freakin hard with very little cooling snow for the slides/engine.

I had new slides and my girlfriend also came along as my passenger.

After riding 500 meters we had to stop cause I was freezing my hands off, before I stopped I heard that the track/slides squeeled. When I then hit the throttle again the track had melted into the slides so the track didnt spin.

I had a friend lift the rear end of the sled and I blipped the throttle so that the track loosened.

We continued riding and it didnt take long before my cooling light came on.

I stopped and put snow on the runningboards.

Continued riding but the cooling light returned and I decided to try to keep out of the trail to get as much cooling snow as possible.

But I did ride with the cooling light on for some time.

I also noticed that the rews were kind of high, does the engagement rpm affect the rpms throughout the hole rpm scale? (I wonder this since my engagement rpm was just under 5000).

So my question is, could the fact that there was little cooling-snow which made the slides hot which again made the track heavy to turn, which again made the engine raise its rpm to keep the track spinning, that in turn made the engine run hotter and because of the lack of cooling snow for the coolers also made the engine run hot?.

Anyway later on the day the trail got softer and I had no problems when we went back to our trailers. We rode about 70km that day.

When we got home I put my sled in the garage to figure out what was wrong with my heated grips. I then noticed that the oil consumption seemed little, I did fill the tank up to the lid before I took my first ride this year, so I thought it had used little oil.

Therefor I aired the pump one more time.

Yesterday we went for a ride back home and the trail was alot softer then it was in Sweden. But due to little snow we had to ride a gnarly trail with low speed, so I did get my cooling light on. I stopped and put snow on the running boards then continued for a 150m and then the rest of the guys decided to stop for a few minutes and then when we continued my cooling light was gone.

We rode up a long hill and in the middle of the hill the sled made a little "boooo burble" but after a split second it was back to normal, and then after 100meters it stopped. I pulled the plugs and found out that the center plug had some aluminium bits on it, so I knew what had happened.

Towed the sled down to the trailer, went home and tore it apart.

Here are some pictures:

Used the oil trick to get the primary off, with a cut down puller.

Did someone try to port it or??

Hmm so now I need to find out were to get parts the cheapest way evey cause I work as an apprentice and my salary sucks.

Gees why does this happen at the beginning of the season?

We havent had ant snow until now (still very little tho) but I guess the snow will come soon.

One thing I forgot to mention is that before yesterdays ride I sealed off the underhood air intakes and installed to flowrites in the gauge pod.

I did not rejet cause I run stock jets so my sled should be rich enough as it is.

And when it burned down we had only ridden about 2 kilometers and I only through those 2 kilometers I dont think I exceeded 7500 rpm or atleast I didnt pin it or anything, careful trail riding with my girlfriend.

I had also added one gram to the heel and got the engagement down to about 4600-4700 which seemed much better. And the clutch setup seemed alot smoother.

As for oil consumption I think I have used about 30 liters of gas this season which should equal an oil consumption up to about 5-600ml I think?

And I have used only 2,5-300ml. I will try to measure this today to get an accurate number.

So my question is:

Is my burn down caused by lack of lubrication or air in the cooling system or both?

This sucks!!!!

I am very sorry for the long thread but I feel that you need all the information to get the right idea on what is going on.

:-)

Any opinions are very welcome!

Thanks

Joakim

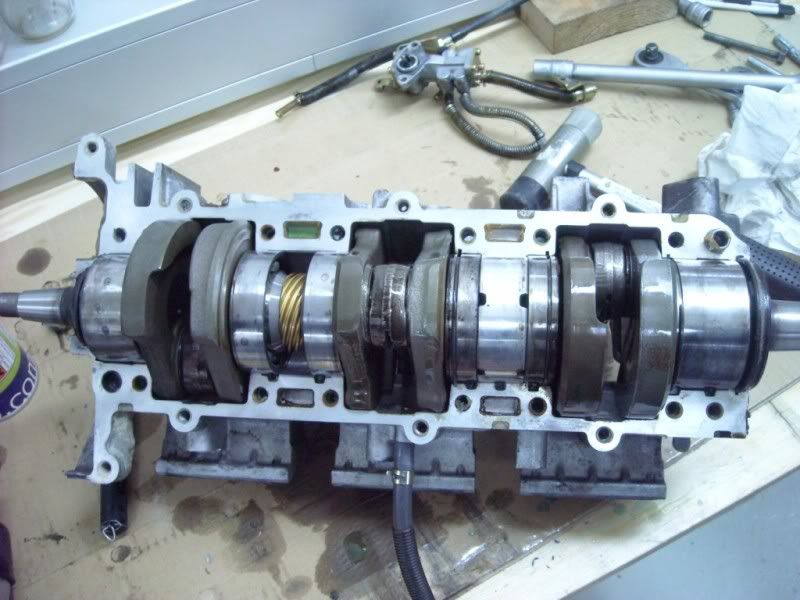

Also as for the crankshaft all the rods feel nice and are OK I think but

large bearing on the mag side seems dry and makes noise when I spin it.

But then again there seemed to be very little oil everywhere in the engine, so I tried to lube the bearing and the noise disappeared. The bearing the is next to the large outer bearing on the PTO side also seems dry and I can almost feel some movement up/down when I try to jiggle it up/down.

Gosh.

$$$$$$$$$ or can I live with it?

large bearing on the mag side seems dry and makes noise when I spin it.

But then again there seemed to be very little oil everywhere in the engine, so I tried to lube the bearing and the noise disappeared. The bearing the is next to the large outer bearing on the PTO side also seems dry and I can almost feel some movement up/down when I try to jiggle it up/down.

Gosh.

$$$$$$$$$ or can I live with it?

Sorry your sled is down. Lots of good pictures for people to diagnose possible causes + solutions.

Heres M.02c:

Engine Temperature:

Normally the jetting we all run in our sleds, to make safe reliable power, is all based and tested on your engine running at a safe coolant/engine temp. As the temp of the engine rises[especially the cylinder heads] the sled will begin to detonate much easier on what was previously a safe jetting. Jetting + engine temp must be balanced to prevent detonation. High engine temp can trigger detonation just like lean jetting can.

Oil Consumtion:

The harder an engine is working, and the higher its temp ,the more important the quality + quantity of oil supply becomes.

30ml of oil to 30 litres of fuel is approx - 100 : 1 The general concensis for oil useage for a trail sled is approx 50 : 1

IMO:

I think you have a few issues that have caused your problem:

-high engine temp combined with your current jetting caused detonation that erroded the piston crown on the exhaust side. Detonation is VERY HARD on the crankshaft rod bearings as well.

-marginal oil supply to the engine + crankshaft bearings that combined with detonation and the resulting very high internal engine temps can result in the crankshaft main +rod bearings failure.{Vipers seem to be prone to the Rod bearing failures as well] Although you said you don't have that problem, make sure you check all the crank bearings closely.

Heres M.02c:

Engine Temperature:

Normally the jetting we all run in our sleds, to make safe reliable power, is all based and tested on your engine running at a safe coolant/engine temp. As the temp of the engine rises[especially the cylinder heads] the sled will begin to detonate much easier on what was previously a safe jetting. Jetting + engine temp must be balanced to prevent detonation. High engine temp can trigger detonation just like lean jetting can.

Oil Consumtion:

The harder an engine is working, and the higher its temp ,the more important the quality + quantity of oil supply becomes.

30ml of oil to 30 litres of fuel is approx - 100 : 1 The general concensis for oil useage for a trail sled is approx 50 : 1

IMO:

I think you have a few issues that have caused your problem:

-high engine temp combined with your current jetting caused detonation that erroded the piston crown on the exhaust side. Detonation is VERY HARD on the crankshaft rod bearings as well.

-marginal oil supply to the engine + crankshaft bearings that combined with detonation and the resulting very high internal engine temps can result in the crankshaft main +rod bearings failure.{Vipers seem to be prone to the Rod bearing failures as well] Although you said you don't have that problem, make sure you check all the crank bearings closely.

Last edited:

2003VIPERER

New member

looked just like mine did went it blew. my problem was the crank seals- sorry to hear about the bad luck- i noticeted a couple guy got some cylinders for sale on hear. should get one around $175.00 us-how does the head look?

That sucks man, I feel for you.

Bob pretty much said it all. I remember when the Viper came out they were bragging about how it used even 25%(I think) less oil then previous sleds. With me I would rather have a little more and be safe.

Also, have you cleaned the carbs? I'm sure you did but as I skimmed through your msg I didn't see that. The only oil your engine will get is through your fuel/air mix in the carburetor. If one main jet is slightly dirty you will have more detonation AS well as less lubrication.

It looks as though someone was doing some grinding. If they did this and did not rejet than that could also be a big problem. Whether it runs more efficient now or not it will probably be passing more air though which means more fuel.

Hope I could help, I know it sucks and thi sis why I was a little worried buying a triple but my srx has been bulletproof. Good Luck!

Bob pretty much said it all. I remember when the Viper came out they were bragging about how it used even 25%(I think) less oil then previous sleds. With me I would rather have a little more and be safe.

Also, have you cleaned the carbs? I'm sure you did but as I skimmed through your msg I didn't see that. The only oil your engine will get is through your fuel/air mix in the carburetor. If one main jet is slightly dirty you will have more detonation AS well as less lubrication.

It looks as though someone was doing some grinding. If they did this and did not rejet than that could also be a big problem. Whether it runs more efficient now or not it will probably be passing more air though which means more fuel.

Hope I could help, I know it sucks and thi sis why I was a little worried buying a triple but my srx has been bulletproof. Good Luck!

you didn'tmake mention of cleaning the carbs. Did you clean them

no1chevyboy

New member

sorry dude! my two cents says that this happened from running hot, possibly lean on that cylinder

mod-it

Member

Sounds like a combination of overheating and waaay low oil consumption.

There is a bleeder for the coolant on Mnt. Vipers. It is under the black rubber plug on the back of the tunnel, right on top behind the seat. Remove the rubber plug and you'll see a bolt that goes down into the rear heat exchanger. There is also a bleeder at the carb heater knob, but this one is tricky to get coolant out of. Sounds like you have to remove the top bolt and then get the carb heater knob to slightly pull out before anyone is successful at getting coolant to flow out of it.

As for bleeding the oil pump, you'll have to do a search on here, I've never had to do that before.

There is a bleeder for the coolant on Mnt. Vipers. It is under the black rubber plug on the back of the tunnel, right on top behind the seat. Remove the rubber plug and you'll see a bolt that goes down into the rear heat exchanger. There is also a bleeder at the carb heater knob, but this one is tricky to get coolant out of. Sounds like you have to remove the top bolt and then get the carb heater knob to slightly pull out before anyone is successful at getting coolant to flow out of it.

As for bleeding the oil pump, you'll have to do a search on here, I've never had to do that before.

I am betting on dirty carbs causing detonation causing overheat. But thats just my theroy.

mopar1rules

Active member

i didn't read thru your first post, i just looked at the pictures and see that someone was trying to do some "PORTING", on the cylinders. in this picture, you can see where the "seal line" was/is, and its right next to there grinding, which was absolutly stupid in that area, as its doing nothing. maybe seeing as the grinding was so close to the "sealing line/area", that you were getting a slight air leak?? here is the pic and area i'm talking about....

Attachments

no1chevyboy

New member

heres the thing if it was an oiling problem it would effect all cylinders,if it was a fuel issue it would effect all cylinders. are there not cooling issues with the viper? along with the single pipe all exhaust flows to the center more heat there, i beleive this is the problem and low snow makes it worse just my 2 cents again!

Hi guys! Thanks SO much for all the replies I really appreciate it!

Yes I did clean my carbs before I took my first ride. I also completely cleaned the airbox and added a prefilter on the top.

I am shocked to find out that there acually is a bleeding screw for the coolant, wish I knew that. I did a search but I couldnt find any info on so I guess that`s my bad, only "guessing" that is was allright.

Is it likely that I had air in my system?

I cannot recall having the temperature light coming on all the time last year. (that said, there is little snow these days).

As for jetting I run stock jets, 156.3 if I remember correctly.

Today I filled up my gas tank to see how much gas I have used, about 22 liters.

So, 22 liters + the gas I used on my first ride, atleast 6-7 liters, makes a total of 29 liters of gas.

I then used a little cup to measure how much oil I had used, only got to add 200ml of oil into the oil tank. There was also some oil that got spilled away when I disconnected the oil line.

Which means: 200ml of oil used on 29liters of gas.

If I were to use 2% oil which is normal for a 2 stroke, I should have used 580ml oil on 29 liters of gas !.

I just discovered something else. I took a look at all the gas hoses that goes to the carbs. On the center hose there is a hole right through it just under an inch from the end (that connects to the carb). The hole barely enters the carb "nipple".

Is it possible that the hole could have let air into the carb and that the center cylinder therefor got a leaner mixture then the other ones?

Will post a picture of the hose later.

I spoke with 2 two stroke specialists and they both said that it must have been suffering from a lean mixture.

However, lack of oil lubrication, too high engine temperature which again causes HEAT inside the cylinder/piston will in turn make it look like it has run lean? Or am I wrong?

One of the guys I spoke with (who is a Yamaha dealer) said that when he had an engine ouf of a sled, he always filled the oil pump hoses with oil before he put the engine back into the frame . He didnt say if he aired while doing so but after the first startup whilst letting the sled idle, he opened the bleed screw and then used his finger to push the oil pump "lever" (that the cable connects to) into full position.

This was the best way to get the air out, he claimed.

However I find it tricky to reach the lever on the oilpump when the engine is fully mounted together, but I guess it can also be done by just pulling at the cable where the adjustment is done.

Also I dunno if I mentioned it before but I also discovered some air bubbles in the oil pump hoses. There is a bubble in the hose that goes up to the bleed screw.

Is it possible that there has been air inside the pump and then when I got it on the bench and rotated it in all kinds of directions, the bubble "loosened" ?

Or could the air have gotten in there after I disconnected the hoses? Hard to say.. .

I would like to comment every reply I get but it is very time consuming.

Thanks alot for the replies again!! :-)

I am now trying to figure out where to buy parts.. .

For 3 pistons, 3 piston pin bearings, pins, circlips, rings, seals, gaskets, cylinder I am looking at a cost around 1650$. Norwegian prices!

And this is for a re-nicasiled cylinder with wisecos.

Stock parts are way more expensive.

So I dunno wether I should get parts from the US (takes alot of time) or if I should buy them here. Hmm

Moparules: I dont think the porting could have caused an air leak, if I understood you correctly. The surfaces look OK.

Wellwell

Yes I did clean my carbs before I took my first ride. I also completely cleaned the airbox and added a prefilter on the top.

I am shocked to find out that there acually is a bleeding screw for the coolant, wish I knew that. I did a search but I couldnt find any info on so I guess that`s my bad, only "guessing" that is was allright.

Is it likely that I had air in my system?

I cannot recall having the temperature light coming on all the time last year. (that said, there is little snow these days).

As for jetting I run stock jets, 156.3 if I remember correctly.

Today I filled up my gas tank to see how much gas I have used, about 22 liters.

So, 22 liters + the gas I used on my first ride, atleast 6-7 liters, makes a total of 29 liters of gas.

I then used a little cup to measure how much oil I had used, only got to add 200ml of oil into the oil tank. There was also some oil that got spilled away when I disconnected the oil line.

Which means: 200ml of oil used on 29liters of gas.

If I were to use 2% oil which is normal for a 2 stroke, I should have used 580ml oil on 29 liters of gas !.

I just discovered something else. I took a look at all the gas hoses that goes to the carbs. On the center hose there is a hole right through it just under an inch from the end (that connects to the carb). The hole barely enters the carb "nipple".

Is it possible that the hole could have let air into the carb and that the center cylinder therefor got a leaner mixture then the other ones?

Will post a picture of the hose later.

I spoke with 2 two stroke specialists and they both said that it must have been suffering from a lean mixture.

However, lack of oil lubrication, too high engine temperature which again causes HEAT inside the cylinder/piston will in turn make it look like it has run lean? Or am I wrong?

One of the guys I spoke with (who is a Yamaha dealer) said that when he had an engine ouf of a sled, he always filled the oil pump hoses with oil before he put the engine back into the frame . He didnt say if he aired while doing so but after the first startup whilst letting the sled idle, he opened the bleed screw and then used his finger to push the oil pump "lever" (that the cable connects to) into full position.

This was the best way to get the air out, he claimed.

However I find it tricky to reach the lever on the oilpump when the engine is fully mounted together, but I guess it can also be done by just pulling at the cable where the adjustment is done.

Also I dunno if I mentioned it before but I also discovered some air bubbles in the oil pump hoses. There is a bubble in the hose that goes up to the bleed screw.

Is it possible that there has been air inside the pump and then when I got it on the bench and rotated it in all kinds of directions, the bubble "loosened" ?

Or could the air have gotten in there after I disconnected the hoses? Hard to say.. .

I would like to comment every reply I get but it is very time consuming.

Thanks alot for the replies again!! :-)

I am now trying to figure out where to buy parts.. .

For 3 pistons, 3 piston pin bearings, pins, circlips, rings, seals, gaskets, cylinder I am looking at a cost around 1650$. Norwegian prices!

And this is for a re-nicasiled cylinder with wisecos.

Stock parts are way more expensive.

So I dunno wether I should get parts from the US (takes alot of time) or if I should buy them here. Hmm

Moparules: I dont think the porting could have caused an air leak, if I understood you correctly. The surfaces look OK.

Wellwell

no1chevyboy

New member

if the other two pistons are in spec and undamaged they can be reused same with there pins and bearings you would only need rings ,

no1chevyboy

New member

as for the cylinder i would clean it with miriatic acid (spelling?) and see how bad it really is

02ViperMtn

Member

i have seen a ton of vipers running at 100:1 on oil. That is not good, but if you ran a decent quality oil i would say the lack of oil is not the primary cause. I would suggest the engine temp or a dirty center carb is the primary cause of failure. Do you have a rear heat exchanger? The engine will over heat with no cooling snow and an extra passenger and over heated hyfax sticking to the track even in -22deg. Were the carbs cleaned?

I guess I could use the other pistons but something tells me they have been hot too because I had a really hard time removing the piston pins.

Guess I can take them to work and measure them properly.

As for the cylinder I think it is shot, it looks really really messy.

Hmm I have to ask, what is a rear heat exchanger? Extra cooling?

Does anybody have a viper manual?

And yes the carbs were cleaned!

However I guess it is possible that something could have blocked the main jet and start the detonation and then get sucked into the engine leaving no evidence?

Hmm.

Where can I get a rear heat exchanger?

Guess I can take them to work and measure them properly.

As for the cylinder I think it is shot, it looks really really messy.

Hmm I have to ask, what is a rear heat exchanger? Extra cooling?

Does anybody have a viper manual?

And yes the carbs were cleaned!

However I guess it is possible that something could have blocked the main jet and start the detonation and then get sucked into the engine leaving no evidence?

Hmm.

Where can I get a rear heat exchanger?

yes heat exchanger is like the ones on the foot wells except it goes across the back of the tunnel ...viper were not made with these til 04 ....so most guys use the exchanger from a srx ....or can even be used from a sx ...but srx has the bigger cooler ...sounds like you need to be looking for one ....