Backwoods M Max

New member

That bowl wasn't that bad for ethanol. I didn't get around to winterizing my sled until late May and all 3 had ethanol poo in the plugs that cover the main jets. This stuff was like a big ball of goo, hopefully ethanol goes away soon.

Agpetro

Member

That bowl wasn't that bad for ethanol. I didn't get around to winterizing my sled until late May and all 3 had ethanol poo in the plugs that cover the main jets. This stuff was like a big ball of goo, hopefully ethanol goes away soon.

I hope the ethanol goes away. All my jets had goo in them, even though I use ethanol treatment in every tank of gas I have. I just put the picture up because there are people out there that still don't think you need to clean you're carbs every year.

Agpetro

Member

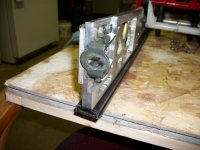

Got my extensions back last night. I give credit to my neighbor Cash for doing such a great job fixing me up. The skid went it so easy having the right length extensions. Before it was a pain it the a$$. Did get the sled back together not to long ago and went for a ride. Still have a few things to do on it but should be done soon.

Attachments

C-Biscuit14

New member

I don't believe its in the sled tolerances, Its the extensions were made too long. Think about it, a 144in track is 23in longer then a 121in. That means the extesions should be 11.5in not their 12 3/8in. That's almost an inch too long they were made.

I see what you are trying to say, but I believe you have to account for the tip up, which is why they are longer than the 11.5in you calculated. An 11.5in tip up would require a shorter track than an 11.5in straight. It's kind of difficult to explain without being able to draw it out, but ultimately, the angle in the tip up reduces the distance the top part of the track has to travel back to the drive shaft. So by tipping up, you actually need a slightly longer extension than you would if it were straight. Hope that makes sense!

Agpetro

Member

I see what you are trying to say, but I believe you have to account for the tip up, which is why they are longer than the 11.5in you calculated. An 11.5in tip up would require a shorter track than an 11.5in straight. It's kind of difficult to explain without being able to draw it out, but ultimately, the angle in the tip up reduces the distance the top part of the track has to travel back to the drive shaft. So by tipping up, you actually need a slightly longer extension than you would if it were straight. Hope that makes sense!

Let me put it this way. I had my neighbor machine it to 11.5in which is what it should be. He has been a machinist his whole life and he said that tip up is not going to make much of a difference in the length of the extension. I explained my measurements to him and he thought the same as I did. They are just way too long... I put the modified extensions in that he fixed for me and they worked perfect. The skid went in so easy. Look at the picture I attached and thats as far as the skid would go up. The track was super tight at that point so tell me how having it longer would even work. Even putting in the skid was a pain before I had them redone. The w arm didn't want to clear the drivers. I actually had to have my dad hold the track up in the back and spin it as i was spinning the track upfront so the w arm would actually spin past the drivers. From all the problems I had with these extensions all I can say is the rail extensions are machined wrong.

Attachments

Devilin AblueDress!

New member

I see where he was going with that theory but I am with you and the neighbor that the 6 or 8 degree tip up isn't going to add up in needs to be the extra length. Seems to me it would need to be double the degree to really start adding length. I would imagine the "exact answer" would have something to do with parts/components from 3 different manufactures (skid/track/extension) each having a "window" of tolerances. In your case they may have added up to machining necessary. Weird how some go right together and others......not so much. Either way.......Got some snow on those new parts Looking good!

Looking good!

Looking good!

Looking good!Agpetro

Member

I see where he was going with that theory but I am with you and the neighbor that the 6 or 8 degree tip up isn't going to add up in needs to be the extra length. Seems to me it would need to be double the degree to really start adding length. I would imagine the "exact answer" would have something to do with parts/components from 3 different manufactures (skid/track/extension) each having a "window" of tolerances. In your case they may have added up to machining necessary. Weird how some go right together and others......not so much. Either way.......Got some snow on those new partsLooking good!

Thanks! Should be going out riding this week sometime. I took a short ride today out in a field to see how it floats. I did find I need to add a hair of ski pressure on it. It turns but needs a hair more pressure I think. To me it handles way better then when it was a shorty. Got to go on a ride to tell out it will handle. I see petoskey snowmobile club has been out grooming already. Saturday I saw the trail was groomed going to the casino. Chris was telling me you guys are going to start grooming sometime this week. Hope the snow keeps coming. If it does we can all thank Chris for it

Lol

LolDevilin AblueDress!

New member

I was told "the week before Christmas" a few times. (primarily due to paperwork/DNR) Got a text this morning wanting to know If I was available to go groom......Busy plowing so I couldn't. I started grooming mid season last year and am a little hesitant on the whole " Hey...go be the first guy out" I assumed one of the other 3 guys would be......Not as of yet. Should be any time now.

A couple of bucks

VIP Member

What the issue on a groomer being the 1st guy out ?am a little hesitant on the whole " Hey...go be the first guy out"

Backwoods M Max

New member

I have found with my mountain max that it never wanted to really cut in and turn on hard packed snow, and on powder forget about it. It wants to be put on its side and carved. Puuuuuuush is the word of the day. I'm even running powder hounds which have a real aggressive keel and it still likes to go straight. Does your sled have multiple holes in the drop bracket? dropping the back of the skid to the lower holes would give you some more ground pressure up front. I went with the hartman spec of 25mm on the limiter strap bolts, but I'm also looking for float.

Devilin AblueDress!

New member

What the issue on a groomer being the 1st guy out ?

I started mid season last year and only have 10-12 under my belt (first 3 was with another groomer riding shot gun). The other 3 guys have 7-10 years experience so I am for sure the nube. Mainly has to due with Pisten bully has ben sitting 8 months (has ben checked over but hasn't ben driven) and the Dubie groomer we pull is AGGRESSIVE. Could easily ruin a trail with it instead of making it better with the snow we have on the ground.

Agpetro

Member

I have found with my mountain max that it never wanted to really cut in and turn on hard packed snow, and on powder forget about it. It wants to be put on its side and carved. Puuuuuuush is the word of the day. I'm even running powder hounds which have a real aggressive keel and it still likes to go straight. Does your sled have multiple holes in the drop bracket? dropping the back of the skid to the lower holes would give you some more ground pressure up front. I went with the hartman spec of 25mm on the limiter strap bolts, but I'm also looking for float.

I dont have drop brackets on it. I know my limiter straps need to be tighten. I've always had them on the long side so I could pull off wheelies. Its really not pushing the sled on the road or in the deep snow. To me it just needs that extra pressure up front. I will be getting some different skis for it next season though so it will float better upfront.

C-Biscuit14

New member

I see where he was going with that theory but I am with you and the neighbor that the 6 or 8 degree tip up isn't going to add up in needs to be the extra length. Seems to me it would need to be double the degree to really start adding length. I would imagine the "exact answer" would have something to do with parts/components from 3 different manufactures (skid/track/extension) each having a "window" of tolerances. In your case they may have added up to machining necessary. Weird how some go right together and others......not so much. Either way.......Got some snow on those new partsLooking good!

Even only a 6 degree tip up can make a surprising difference. (Enough to justifiy a slightly longer rail extension than a straight one would be). Now I think Devilin is probably right with the manufacturer tolerances. While the odds of it happening are slim, you could have the "perfect storm"... a skid at the maximum tolerance, a track at the minimum tolerance, and the rails at the maximum tolerance. Even if they aren't at the maximum tolerance levels, they still add up and could cause problems.

Backwoods M Max

New member

I started mid season last year and only have 10-12 under my belt (first 3 was with another groomer riding shot gun). The other 3 guys have 7-10 years experience so I am for sure the nube. Mainly has to due with Pisten bully has ben sitting 8 months (has ben checked over but hasn't ben driven) and the Dubie groomer we pull is AGGRESSIVE. Could easily ruin a trail with it instead of making it better with the snow we have on the ground.

I've been grooming with my father in law a couple of times over the past few years and driven a little bit here and there. It's easy to scrape too much and fill the pan up. Early season for sure, minimal snow and a questionable base you could bury the drag right down to bare ground. Up in Vermont they go out and pack for days with just the machines before they even take out a drag, and there is so much trail that is in-excess able during the fall that they do a lot of stopping and sawing just to get through.

Agpetro

Member

Even only a 6 degree tip up can make a surprising difference. (Enough to justifiy a slightly longer rail extension than a straight one would be). Now I think Devilin is probably right with the manufacturer tolerances. While the odds of it happening are slim, you could have the "perfect storm"... a skid at the maximum tolerance, a track at the minimum tolerance, and the rails at the maximum tolerance. Even if they aren't at the maximum tolerance levels, they still add up and could cause problems.

I find it very odd that the first post you did on here was about my rail extensions and how my figuring is wrong. Im guessing you work for tracks USA or had a part in machining them since you keep telling me they should be longer with the tip up. How can you justify on inch longer for a little 6 degree tip up?? I also measured my track and it was a 144, measurements were right on. If the skid was off why would my 121in track go in so easy?? I measured the 121 track and of course right on too! From the front of my rail slot to the front of the new rail slot on the extension was 12 3/8in so an inch longer. I called tracks usa and they came up with the same measurement as I did. Its simple math they were machine too long end of story...

Look at these pics and look at the difference on the rails with the idler wheels. My adjustment is all the way forward too!!!

The red one is mine and look at how far back the idlers are in the first pic ( before i got them machined)

The other pictures are from Super1c same rail extensions as me but from last fall.

See how his and mine look the same now on the top since I had it machined. The third triangle on the top part of the rail is just showing.

Attachments

Last edited:

super1c

Super Moderator

WOW i see what you mean now. They are not even close before and after machine done. Ill be up next weekend again for a ride and just for $hit$ and giggles i try to get a measuring tape in there and take some measurements for you to compare. I would have this last weekend but i didnt even think about it as you got it squared away. By the way awesome job, it looks great. To help with the ski pressure i would put some more preload on the front shocks. You are not going to be able to get a lot of ski pressure back from adjusting the skid, the geometry is different. I would set it up with no preload rear center shock and rear shock preload for 40/60 gap (40 gap on top) and pulling the limiters up will help some. I am also running my limiters at the hartman specs of 25mm. I found the key is to get some deep keel skis and nice carbides to get your front end back. I run c&a's with bergstroms and this thing will do circles on a dime. I am thinking of letting the limiters out a bit to get rid of some of the ski pressure now. I also run transfer rods per hartman specs (dont remember off hand). The stock viper skis with short keel are a killer after long tracking!

Agpetro

Member

WOW i see what you mean now. They are not even close before and after machine done. Ill be up next weekend again for a ride and just for $hit$ and giggles i try to get a measuring tape in there and take some measurements for you to compare. I would have this last weekend but i didnt even think about it as you got it squared away. By the way awesome job, it looks great. To help with the ski pressure i would put some more preload on the front shocks. You are not going to be able to get a lot of ski pressure back from adjusting the skid, the geometry is different. I would set it up with no preload rear center shock and rear shock preload for 40/60 gap (40 gap on top) and pulling the limiters up will help some. I am also running my limiters at the hartman specs of 25mm. I found the key is to get some deep keel skis and nice carbides to get your front end back. I run c&a's with bergstroms and this thing will do circles on a dime. I am thinking of letting the limiters out a bit to get rid of some of the ski pressure now. I also run transfer rods per hartman specs (dont remember off hand). The stock viper skis with short keel are a killer after long tracking!

I dont know if you recall but before Tracks usa had the website redone I thought they said 11.5in rail extensions not 12in. We will find out once you measure up yours. Then we will know. I know the guy I talked to said this is the third version I have.

C-Biscuit14

New member

I find it very odd that the first post you did on here was about my rail extensions and how my figuring is wrong. Im guessing you work for tracks USA or had a part in machining them since you keep telling me they should be longer with the tip up. How can you justify on inch longer for a little 6 degree tip up?? I also measured my track and it was a 144, measurements were right on. If the skid was off why would my 121in track go in so easy?? I measured the 121 track and of course right on too! From the front of my rail slot to the front of the new rail slot on the extension was 12 3/8in so an inch longer. I called tracks usa and they came up with the same measurement as I did. Its simple math they were machine too long end of story...

I don't work for Tracks USA nor am I affiliated with them in any way. Everybody has to make a first post at some point, I guess everyone must work for some company in order to make a first post? I digress.... I was simply offering you an explanation of why the rail was longer than the 11.5 you said it should be. I agree with you that you clearly got a bad rail extension. Especially if it was 12.5" when they should be only 12". But just for the sake of making a snarky comment.... math, math is how I can justify a longer extension with a 6 degree tip up. I just did a rough calculation and found that about a 0.5" longer extension would be needed with the tip up. 11.5 + 0.5 = 12.0

You got a bad extension, you got it fixed, I guess that's all that really matters.

I just got my rail extension in from them and I am hoping it will go better for me than it did for you.

Last edited:

Agpetro

Member

I don't work for Tracks USA nor am I affiliated with them in any way. Everybody has to make a first post at some point, I guess everyone must work for some company in order to make a first post? I digress.... I was simply offering you an explanation of why the rail was longer than the 11.5 you said it should be. I agree with you that you clearly got a bad rail extension. Especially if it was 12.5" when they should be only 12". But just for the sake of making a snarky comment.... math, math is how I can justify a longer extension with a 6 degree tip up. I just did a rough calculation and found that about a 0.5" longer extension would be needed with the tip up. 11.5 + 0.5 = 12.0

You got a bad extension, you got it fixed, I guess that's all that really matters.

I just got my rail extension in from them and I am hoping it will go better for me than it did for you.

I didn't get a bad extension, it actually measured the same as what they had. I called Tracks USA and my measurement was the same as what they had. So I have what they got at the warehouse. I just thought how you were talking sounded like you were one of the guys from Tracks USA. But anyways welcome to the site. Hope you don't have to go through all the trouble I had to. What are you long tracking by the way??

C-Biscuit14

New member

I didn't get a bad extension, it actually measured the same as what they had. I called Tracks USA and my measurement was the same as what they had. So I have what they got at the warehouse. I just thought how you were talking sounded like you were one of the guys from Tracks USA. But anyways welcome to the site. Hope you don't have to go through all the trouble I had to. What are you long tracking by the way??

I don't understand why they would advertise it as 12" and then machine it to almost half an inch longer, but I guess they have their reasons. I forgot to check what mine was last night... I'm sure it will be the 12 3/8 like you if that's what they are selling.

I'm long tracking my 99 Vmax SX 600. Hopefully start on it tonight....who knows how long it will take if I have to get it machined somewhere!