supercharged111

Member

I left the shelf in and drilled holes in it.

How many/how big of holes did you drill? I'm getting the itch to do this but need to grab some main jets first.

supercharged111

Member

Yes a heated garaged is a must around here. I currently still have the green spring at 70 degrees. Thunder Clutching products has different helixes.

After the 20 minute call I had with them, I almost wish I would've just called them from the start for their set up for a piped redhead. If the next week of testing doesn't go well I'm not sure what I'll do next, winter is already half over, so it may just go back to stock for the third time.

I was also told that if you are removing the outer clutch cover, to pull the primary bolt out, and the spring/lock washer often will be the item damaging the outer bushing.

If you get a taste of 9000 you're never going to want to go back to a single pipe.

Go to TY Home tech pages and Snowmobile tech then EngineHow many/how big of holes did you drill? I'm getting the itch to do this but need to grab some main jets first.

All the instructions are there.

For the last couple decades the only place I get my Secondary Helixs is from Dalton....top quality and consistent angles.

supercharged111

Member

And there it is, I thought it was a bunch of 1" holes. Time to order jets. I ended up weighing the hardware store rivets on a more accurate scale today and here's what I've found:

aluminum rivet with aluminum washer 1.0g

Steel rivet 2.0g

Steel washer 1.3g

So last night I added 2.3g to the inner hole. Slapped it on, went for a rip, sled was right about 8700-8800. You'd think that's perfect but it wasn't very snappy, so off came the 47 degree helix and red spring at 70 degrees, on went the 45 degree helix with green spring wound up to 70, and it's a bit snappier but touching over 9000 again. I'm thinking the reason it felt off at first is because it was taking longer to get on the pipe with the lazier backshift having to slog through the bit where it doesn't want to be but it still hit triple digits at 8700-8800 so there's plenty of chooch there once it's wound up. I'm thinking I'll shoot for 8900 or so since it's cold out, I'll probably lose a little when it warms back up and the trails get sloppy. Plus should help it get on the pipe sooner. Off came the primary again and I swapped the outer 1.0g aluminum rivets with washers for steel rivets without washers, so I now have 3.3g in the inner hole and 2.0g in the outer hole. If 2.0 isn't quite enough I can combine an aluminum rivet with a steel washer to hit a touch over 2g. I'll see what that does tomorrow when the kids are in school. I'm currently waiting on 2.44g, 2.7g, 3.1g, and 3.6g Yamaha rivets to arrive in the mail.

aluminum rivet with aluminum washer 1.0g

Steel rivet 2.0g

Steel washer 1.3g

So last night I added 2.3g to the inner hole. Slapped it on, went for a rip, sled was right about 8700-8800. You'd think that's perfect but it wasn't very snappy, so off came the 47 degree helix and red spring at 70 degrees, on went the 45 degree helix with green spring wound up to 70, and it's a bit snappier but touching over 9000 again. I'm thinking the reason it felt off at first is because it was taking longer to get on the pipe with the lazier backshift having to slog through the bit where it doesn't want to be but it still hit triple digits at 8700-8800 so there's plenty of chooch there once it's wound up. I'm thinking I'll shoot for 8900 or so since it's cold out, I'll probably lose a little when it warms back up and the trails get sloppy. Plus should help it get on the pipe sooner. Off came the primary again and I swapped the outer 1.0g aluminum rivets with washers for steel rivets without washers, so I now have 3.3g in the inner hole and 2.0g in the outer hole. If 2.0 isn't quite enough I can combine an aluminum rivet with a steel washer to hit a touch over 2g. I'll see what that does tomorrow when the kids are in school. I'm currently waiting on 2.44g, 2.7g, 3.1g, and 3.6g Yamaha rivets to arrive in the mail.

Last edited:

Mine likes 9000 RPM with SLP Pipes, 8700-8800- is too low IMO.

Peak Seeker

Member

- Joined

- Oct 2, 2025

- Messages

- 50

supercharged111

Member

Mine likes 9000 RPM with SLP Pipes, 8700-8800- is too low IMO.

I wonder if the tach is off just a smidge? It does sound different at 9000 vs 8700. Today I got into it with the latest setup and the tach was right up on the 9 line, maybe on the low side of it, but didn't go past. Felt right on the money. Later in my journey I got into some slop and it was dragged down around 8800 or so. I think this is where it should stay though? 9000 for when it's good, then just live with it dragging a bit when there's extra resistance? Or maybe I just need to ride it more to better characterize it as it is now. I may need the same amount of weight, but a touch less in the tip.

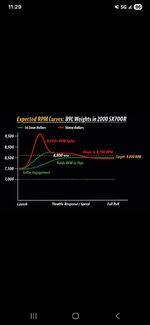

Just using ChatGPT to get some AI insight on my clutching and here's a graph in tossed together for me showing RPM curve change with the 89L weights and the different rollers. While I don't 100% agree with everything it says, it's definitely an excellent resource for troubleshooting. View attachment 68110

I'm not yet a fan of AI for this kind of stuff. All it does is google stuff and sometimes it can't even accurately repeat that, assuming what it found wasn't wrong in the first place. I really like using it to reword stuff.

Peak Seeker

Member

- Joined

- Oct 2, 2025

- Messages

- 50

Alright I removed my primary, replaced the outer cover bushing and ran the whole primary through a few cycles in my ultrasonic cleaner.

Haven't used it for sled clutches before, it'll now become a spring maintenance item because it made a huge difference that an air compressor just can't.

It was -21C (-6F) this morning so my ride was a little crisp but it was at least sunny.

I can confidently say the bushing and clean helped. There was an overall improvement. It would peak at ~9000 rpm then fade to 8500 and hold it steady. I could get about 130km/hr before running out of straight space. Definitely feels like it's closer, but still not there. Backing off and punching it, the backshift felt lazy still.

Clutch settings currently:

Empty 8CR weights

BWB Spring

16mm rollers

Green secondary @ 70 degrees

51-43 RX1 helix.

I put new bushings into the 89L weights last night as well. I'm going to throw them in right now empty and see what that does for me shortly here this morning.

Haven't used it for sled clutches before, it'll now become a spring maintenance item because it made a huge difference that an air compressor just can't.

It was -21C (-6F) this morning so my ride was a little crisp but it was at least sunny.

I can confidently say the bushing and clean helped. There was an overall improvement. It would peak at ~9000 rpm then fade to 8500 and hold it steady. I could get about 130km/hr before running out of straight space. Definitely feels like it's closer, but still not there. Backing off and punching it, the backshift felt lazy still.

Clutch settings currently:

Empty 8CR weights

BWB Spring

16mm rollers

Green secondary @ 70 degrees

51-43 RX1 helix.

I put new bushings into the 89L weights last night as well. I'm going to throw them in right now empty and see what that does for me shortly here this morning.

Peak Seeker

Member

- Joined

- Oct 2, 2025

- Messages

- 50

I was yet again let down hoping for a miracle cure

So same clutch set up as before but with empty 89L's, resulted in:

Peak 8500rpm

Loaded rpm 7500rpm

Top speed 110km/hr

I preferred this shift curve a bit, felt more consisted, and pulled through the mid range vs the 8CR weights. However, I'm way short on rpm.

Next step is to throw in the new 14.5 mm Fett Bros rollers. And one more quick test ride, then I'll have to wait until Sunday, which will change things up a bit as it warms up to -6C.

The Turk clutch suggestions are 89Ls, 14.5 rollers stock springs so we'll see if I should've just gone with that all along.

So same clutch set up as before but with empty 89L's, resulted in:

Peak 8500rpm

Loaded rpm 7500rpm

Top speed 110km/hr

I preferred this shift curve a bit, felt more consisted, and pulled through the mid range vs the 8CR weights. However, I'm way short on rpm.

Next step is to throw in the new 14.5 mm Fett Bros rollers. And one more quick test ride, then I'll have to wait until Sunday, which will change things up a bit as it warms up to -6C.

The Turk clutch suggestions are 89Ls, 14.5 rollers stock springs so we'll see if I should've just gone with that all along.

Peak Seeker

Member

- Joined

- Oct 2, 2025

- Messages

- 50

Ok last test ride of the day done.

There was some improvement with the smaller rollers. It seemed to upshift a little faster, and it was a list less lazy with the backshift. Which makes sense, essentially smaller rollers just applies more force by letting the weights swing out further closing the primary sheave quicker.

The 14.5mm rollers brought me up to a slightly higher top speed, higher loaded rpm around 7800rpm, and it seemed to peak a little lower by a couple hundred rpm. Which I like.

It also dropped engagement rpm from 4900-5000 to 4700-4800.

If I can get it to have this shift curve but bump everything up 1000rpm I'd be perfect.

Not sure what to do for a next step here, I have another secondary spring that Thunder clutching sent me. I may try that, and then that with the 8CR weights. Or possibly just throw the YGY stock spring back in to drop engagement rpm a touch and final rpm.

When I had the clutch apart for cleaning I noticed the slider shoe thing on the primary had some slop, obviously there has to be some, just not sure what the limit on that would be.

I'l get back to troubleshooting this thing tomorrow or Sunday some time hopefully.

There was some improvement with the smaller rollers. It seemed to upshift a little faster, and it was a list less lazy with the backshift. Which makes sense, essentially smaller rollers just applies more force by letting the weights swing out further closing the primary sheave quicker.

The 14.5mm rollers brought me up to a slightly higher top speed, higher loaded rpm around 7800rpm, and it seemed to peak a little lower by a couple hundred rpm. Which I like.

It also dropped engagement rpm from 4900-5000 to 4700-4800.

If I can get it to have this shift curve but bump everything up 1000rpm I'd be perfect.

Not sure what to do for a next step here, I have another secondary spring that Thunder clutching sent me. I may try that, and then that with the 8CR weights. Or possibly just throw the YGY stock spring back in to drop engagement rpm a touch and final rpm.

When I had the clutch apart for cleaning I noticed the slider shoe thing on the primary had some slop, obviously there has to be some, just not sure what the limit on that would be.

I'l get back to troubleshooting this thing tomorrow or Sunday some time hopefully.

supercharged111

Member

Try to get your RPM out of the primary, that's where you should be getting it from. Only way up is a stiffer spring. I choked the secondary in a desperate attempt to shed RPM but wound it back up once I got the primary toned down.

Peak Seeker

Member

- Joined

- Oct 2, 2025

- Messages

- 50

I'll put the factory YGY spring back in and see. It has a stiffer total force. Remind me, what spring you do you currently have?Try to get your RPM out of the primary, that's where you should be getting it from. Only way up is a stiffer spring. I choked the secondary in a desperate attempt to shed RPM but wound it back up once I got the primary toned down.

supercharged111

Member

WSW with a short spring/cover. About to pull the trigger on a used SXR primary to get the longer spring, cover, and weights to play with.

Peak Seeker

Member

- Joined

- Oct 2, 2025

- Messages

- 50

Yeah mine came with the longer cover, as it's an SXR. Your wsw is lower initial and total force than either of my springs. But I don't know what affect the different springs has as far as length goes.WSW with a short spring/cover. About to pull the trigger on a used SXR primary to get the longer spring, cover, and weights to play with.

supercharged111

Member

Yeah mine came with the longer cover, as it's an SXR. Your wsw is lower initial and total force than either of my springs. But I don't know what affect the different springs has as far as length goes.

The problem with the shorter springs is I can only go up 1 from where I'm at and no options to bump engagement RPM. With the longer springs I have more options.

supercharged111

Member

I got more rivets in the mail today and weighed the hardware store stuff vs the Yamaha stuff. The way I see it the accuracy isn't what's important, rather the repeatability. I'm showing about 0.1g lighter than advertised on my scale, but to me it's all relative. So tomorrow I'll yoink the primary back off and press in about the same amount of weight but have it more evenly distributed. Right now there's 3.3g on the inner hole and 2.0g in the outer hole so 5.3g total. 2 of the 2.6g weights will give me 5.2g total but whack the engine in the nuts less in the midrange. We'll see how it shifts with that combo, hopefully it doesn't drag it down up top. But the only way to see is to put them in.

Peak Seeker

Member

- Joined

- Oct 2, 2025

- Messages

- 50

Test rip to the gas station and back with some more results.

Swapped out the BWB for a YGY. As expected it gained me ~200rpm when flat out. For about 8000rpm @115km/hr.

So I'm still almost 1000rpm short with empty 89L weights.

Now I'll try again with the empty 8CR weights and see what it gets me with the 14.5mm rollers and YGY spring. If the previous results all add up, my peak should be around 9000 rpm (was 9000 rpm with the empty 8CRs before, +200 rpm from the heavier spring, -200rpm from the 14.5mm rollers) and my WOT loaded pull should be up around 8800rpm.

Wish me luck, will report back in an hour.

Swapped out the BWB for a YGY. As expected it gained me ~200rpm when flat out. For about 8000rpm @115km/hr.

So I'm still almost 1000rpm short with empty 89L weights.

Now I'll try again with the empty 8CR weights and see what it gets me with the 14.5mm rollers and YGY spring. If the previous results all add up, my peak should be around 9000 rpm (was 9000 rpm with the empty 8CRs before, +200 rpm from the heavier spring, -200rpm from the 14.5mm rollers) and my WOT loaded pull should be up around 8800rpm.

Wish me luck, will report back in an hour.

Peak Seeker

Member

- Joined

- Oct 2, 2025

- Messages

- 50

Alright so YGY, empty 8CR's, 14.5mm rollers.

This tamed the initial peak, however vs the BWB spring and 16mm rollers I lost some top speed. Overall the shift curve was flat which I like. Though I still peaked at 8600rpm and 115-120km/hr after a long steady pull.

I'm running out of ideas on what to do. I will say I could run a Nascar pit crew on removing and swapping out the primary parts haha.

I have a Midnight Blue thunder products secondary spring to try out for my last possible improvement.

Attached is a photo of some sharpie on ny primary showing where it's shifting out to. Clearly it's not shifting all the way out by a fair margin.

This is after the last four or so test set ups, none of them are shifting all the way out.

This tamed the initial peak, however vs the BWB spring and 16mm rollers I lost some top speed. Overall the shift curve was flat which I like. Though I still peaked at 8600rpm and 115-120km/hr after a long steady pull.

I'm running out of ideas on what to do. I will say I could run a Nascar pit crew on removing and swapping out the primary parts haha.

I have a Midnight Blue thunder products secondary spring to try out for my last possible improvement.

Attached is a photo of some sharpie on ny primary showing where it's shifting out to. Clearly it's not shifting all the way out by a fair margin.

This is after the last four or so test set ups, none of them are shifting all the way out.

Attachments

supercharged111

Member

Too bad you weren't closer, you could just pop my clutch on and see if it doesn't flat out work. Today I picked up a tall clutch cover, a YGY spring, and some 16mm rollers. I also found some 8DF weights on eBay for $40 so snatched those. When they arrive I can try that combo. In the meantime I just need to see what happens when I redistribute the weight in the primaries I have now.